Section 04 ENGINE (2-STROKE)

Subsection 02 (REMOVAL AND INSTALLATION)

F02D09B

1

2

1

Loctite

243

Loctite

243

Loctite

243

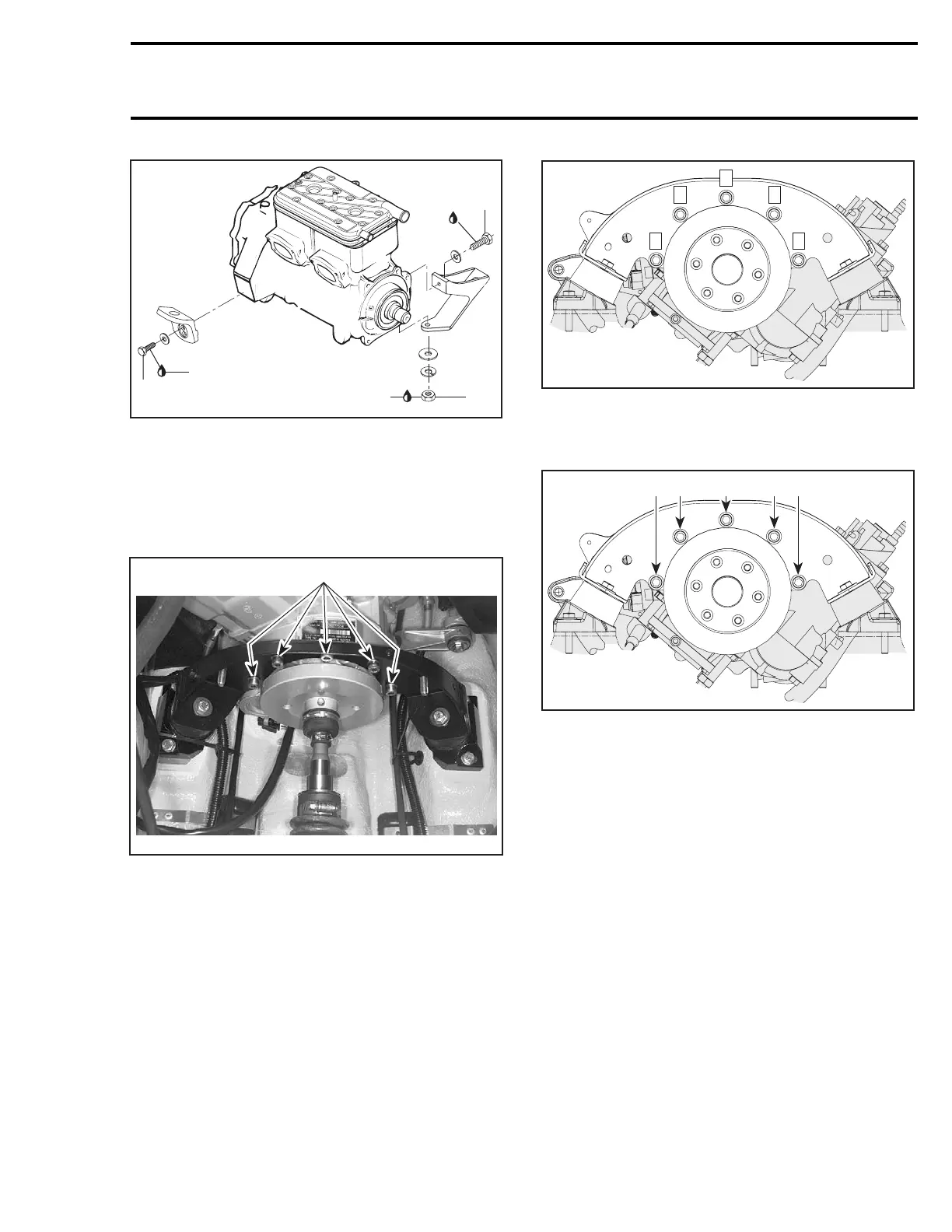

1. Torque screws to 22 N•m (16 lbf•ft)

2. Torque nuts to 39 N•m (29 lbf•ft)

787 RFI Engines

Apply Loctite 243 (blue) to rear engine support

screws and install them with flat washers and

torque to 24 N•m(17lbf•ft).

1

F07F12B

TYPICAL

1. Torque engine support screws to 24 N•m(17lbf•ft)

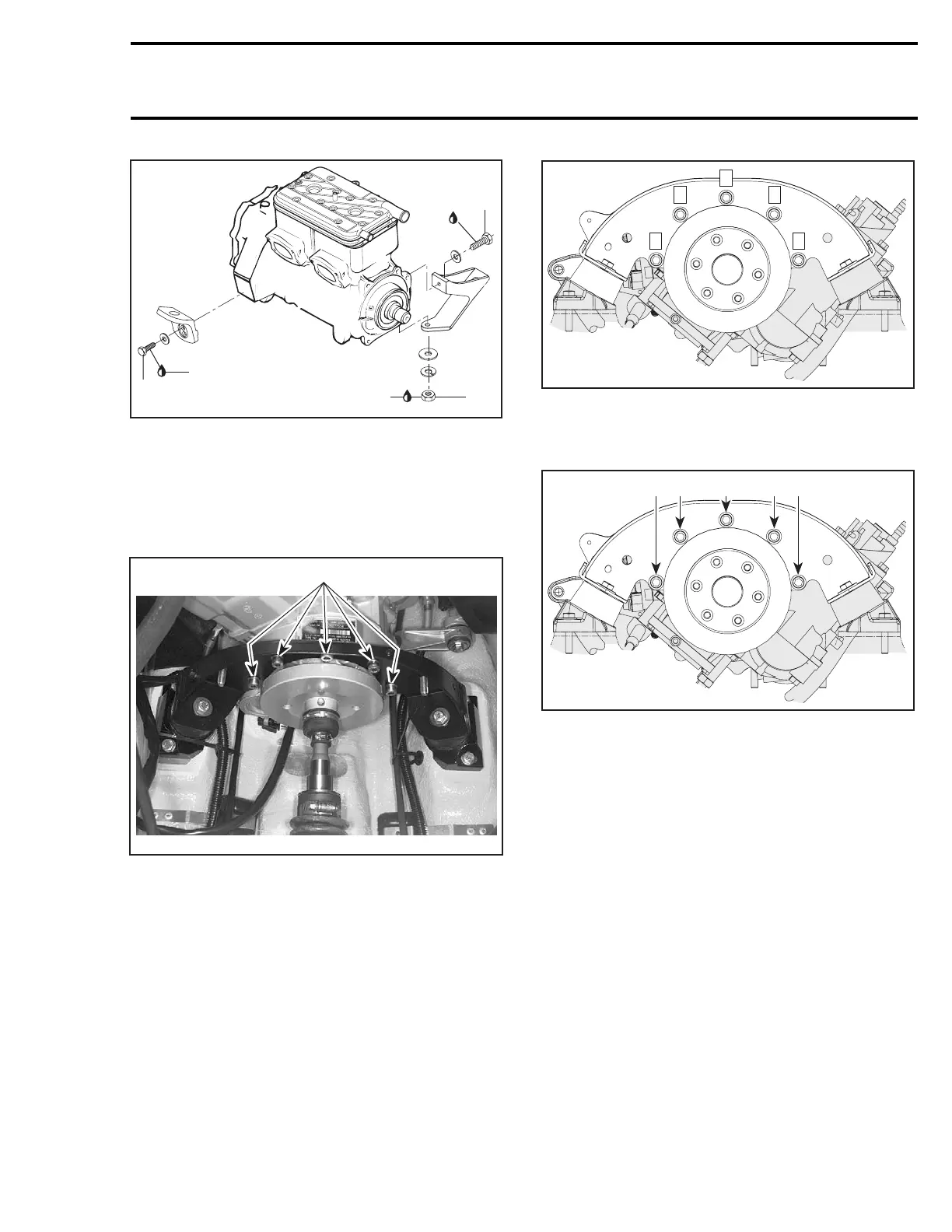

947 DI Engines

Install and torque the engine support screws to

24 N•m(17lbf•ft) in the indicated order. Refer to

the following illustration.

3

F12D13A

1

4

2

5

TORQUE TO 24 N•M(17LBF•FT) AS PER SEQUENCE

NOTE: Remember to install sleeves and flat wash-

ers.

F12D13B

2 1 212

1. Sleeves

2. Flats washers

Oil Injection Hoses

717 and 787 RFI Engines

Make sure to reinstall hoses before completely

lowering engine in bilge.

Positive Starter Cable

Torque nut of positive starter cable to 6 N•m

(53 lbf•in). Apply dielectric grease on nut.

Engine/Jet Pump Alignment

Alignment is necessary to eliminate possible vi-

bration and/or damage to components. Check

alignment of engine using the following alignment

tools.

Support plate kit (P/N 529 035 506).

Use plate (P/N 529 035 507).

smr2004-Complete Line Up 77

Loading...

Loading...