Section 04 ENGINE (2-STROKE)

Subsection 05 (BOTTOM END)

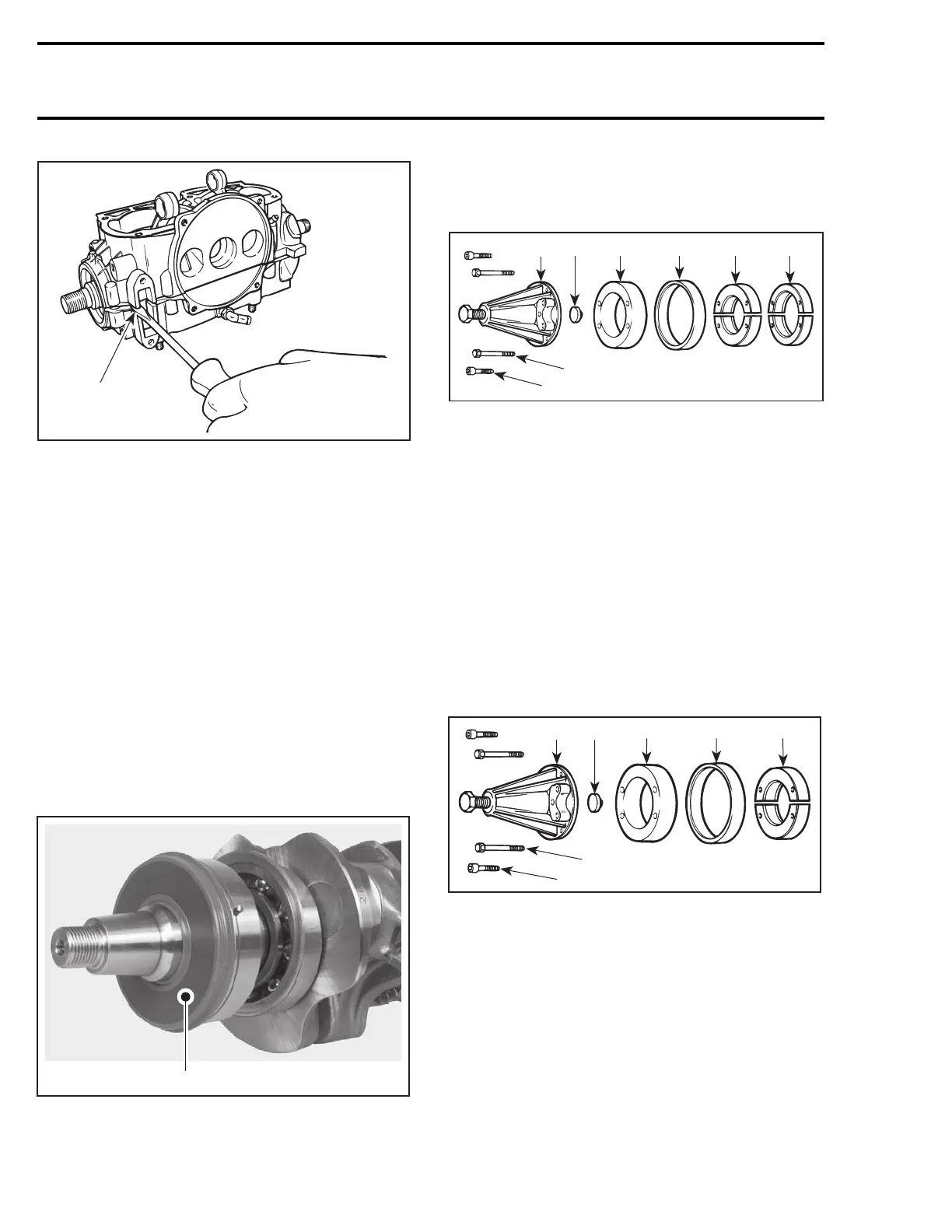

F01D1LA

1

TYPICAL

1. Separate halves by prying at provided lugs

Remove crankshaft and counterbalance shaft (787

RFIand947DIengines).

947 DI Engines

Open air compressor and disconnect the piston as

described in ENGINE MANAGEMENT.

Crankshaft Bearing and Seal

All Engines

If a crankshaft end seal no. 5 hastobereplaced,

bottom end must be opened (except for the MAG

side seal on the 787 RFI engines, which is mount-

ed on the magneto housing).

NOTE: Do not needlessly remove crankshaft bear-

ings.

Remove end seal(s).

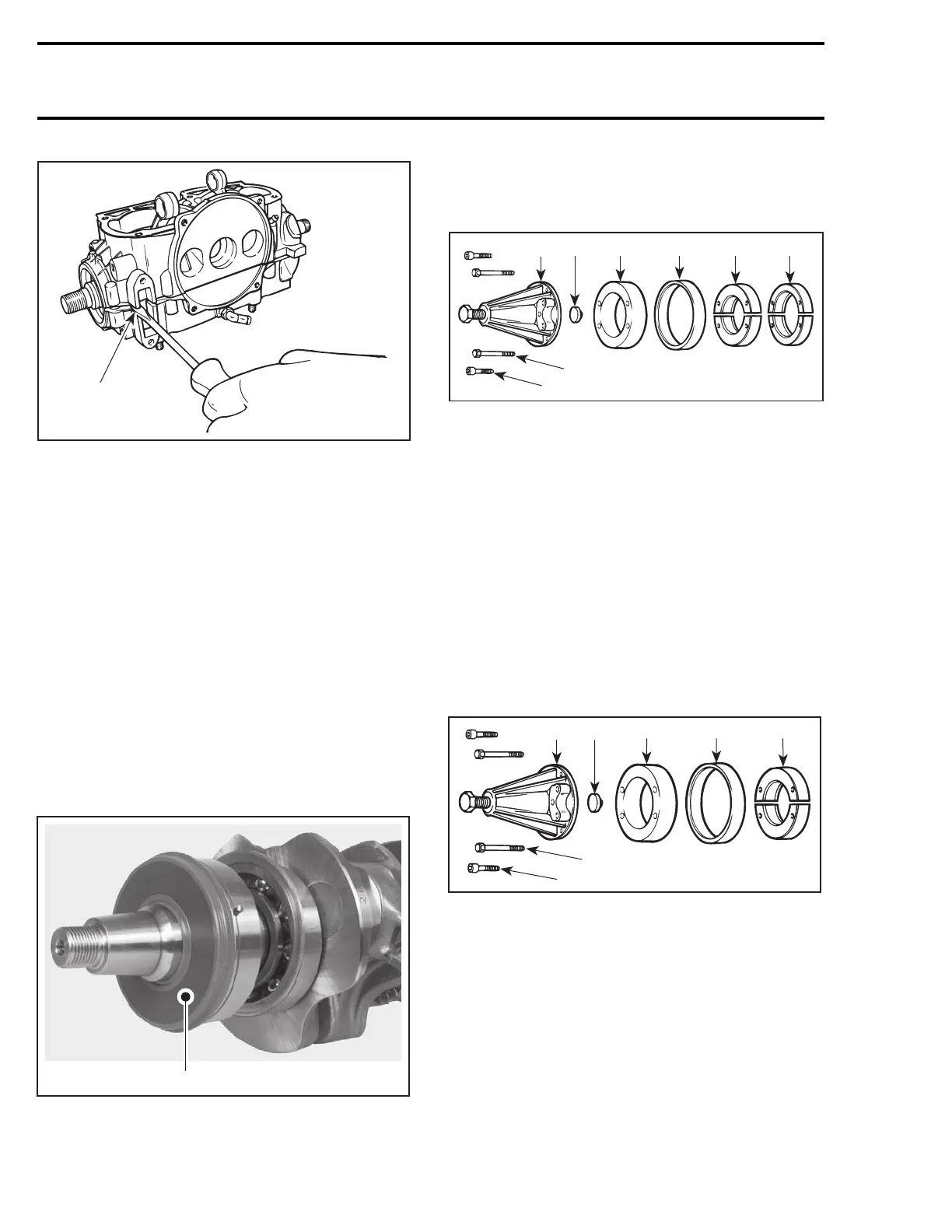

F06D1GA

1

TYPICAL

1. End seal

717 Engines

To remove end bearings no. 4 from crankshaft,

use the following tools.

1

5

3

2

7

8

F01B09A

4

6

717 ENGINES

1. Puller (P/N 420 877 635)

2. Protective cap (P/N 420 876 557)

3. Distance ring, MAG side only (P/N 420 876 569)

4. Ring (both sides) (P/N 420 977 490)

5. MAG side ring halves (P/N 420 276 025)

6. PTO side ring halves (P/N 420 977 475)

7. Screw M8 x 40 (P/N 420 840 681)

8. Screw M8 x 70 (P/N 420 841 201)

NOTE: To facilitate ring or distance ring installa-

tion, lubricate their inside diameters.

787 RFI Engines

To remove end bearings no. 4 from crankshaft,

use the following tools.

NOTE: The outer PTO bearing and crankshaft gear

can be removed in one step using another puller.

See CRANKSHAFT GEAR no. 18.

F01B2MA

12 3 5

7

6

4

787 RFI ENGINES

1. Puller (P/N 420 877 635)

2. Protective cap (P/N 420 876 557)

3. Distance ring (P/N 420 876 569)

4. Ring (P/N 420 977 490)

5. Ring halves (P/N 420 977 475)

6. Screw M8 x 40 (P/N 420 840 681)

7. Screw M8 x 70 (P/N 420 841 201)

NOTE: To facilitate ring or distance ring installa-

tion, lubricate their inside diameters.

947 DI Engines

To remove end bearings from crankshaft, use the

following tools.

136 smr2004-Complete Line Up

Loading...

Loading...