Section 05 ENGINE (4-TEC)

Subsection 08 (ENGINE BLOCK)

NOTE: It is recommended to apply this specific

sealant as described here to get an uniform appli-

cation without lumps. If you do not use the roller

method, you may use your finger to uniformly dis-

tribute the sealant (unlike the Drei Bond sealing

compound, using a finger will not affect the adhe-

sion).

Use the silicone-based Loctite 5910 (P/N 293 800

081) on mating surfaces.

CAUTION: Do not use Loctite 515 or 518 to seal

crankcase. Do not use Loctite Primer N with

the Loctite 5910. Using these products or non

silicone-based sealant over a previously sealed

crankcase with Loctite 5910 will lead to poor

adhesion and possibly a leaking crankcase.

These products are chemically incompatibles.

Even after cleaning, the Loctite 5910 would

leave incompatible microscopic particles.

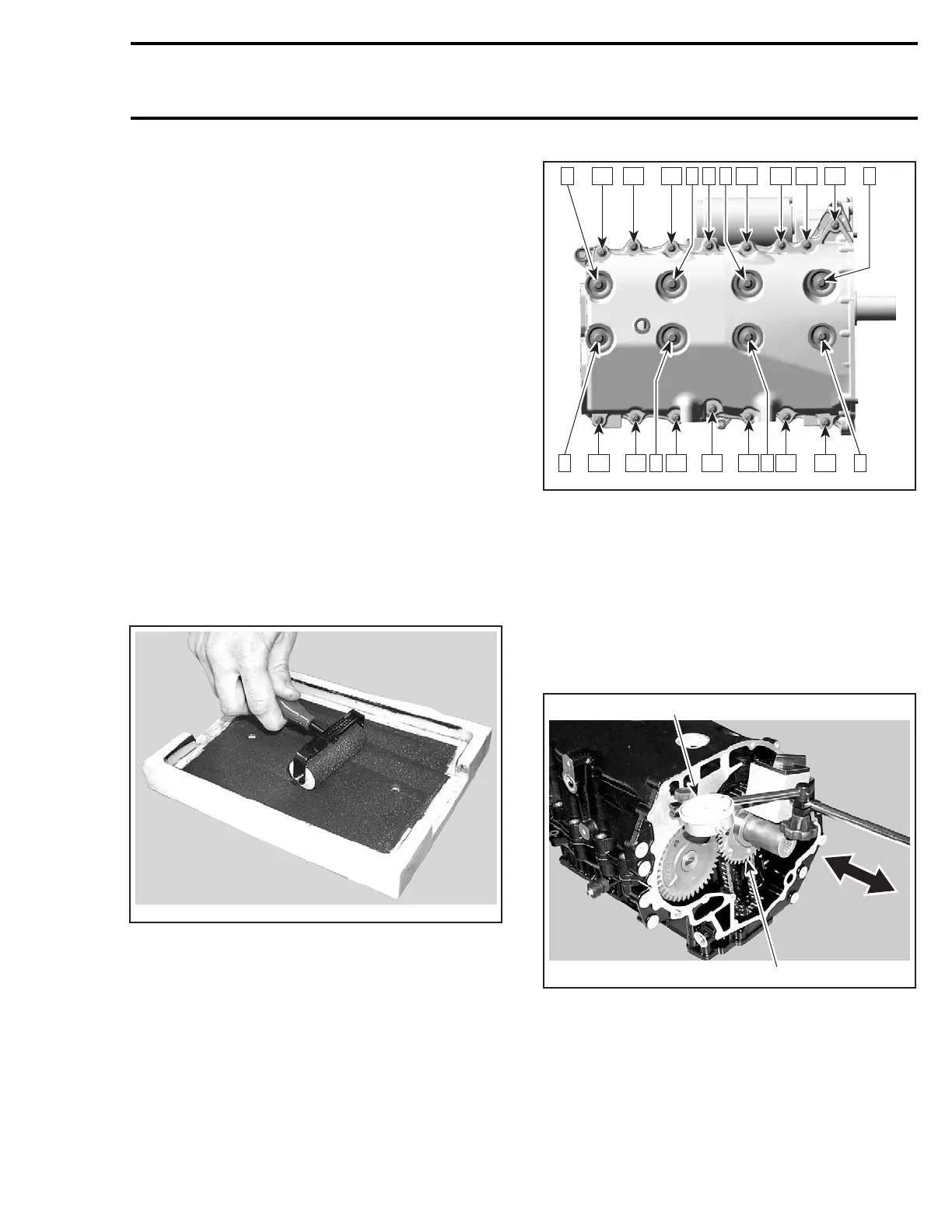

Use a plexiglass plate and apply some sealant on

it. Use a soft rubber roller (50 - 75 mm (2 - 3 in))

(available in arts products suppliers for printmak-

ing) and roll the sealant to get a thin uniform coat

on the plate (spread as necessary). When ready,

apply the sealant on crankcase mating surfaces.

F12R17A

Do not apply in excess as it will spread out inside

crankcase.

NOTE: Do not use Loctite Primer N with this

sealant. The sealant curing time is similar to the

Loctite 518 without using the Primer N, which is

4to24hours.

Tighten engine block screws as per following se-

quence.

3 1 7

R1503motr06B

235 21 17 18 19 2022

16 15 14 9 2 10 11 12 136 84

Apply Loctite 243 (blue) on threads. Torque

engine block screws no. 3 at first to 40 N•m

(29 lbf•ft) and in a second sequence to 55 N•m

(41 lbf•ft).

Torque engine block screws no. 7 to 22 N•m

(17 lbf•ft).

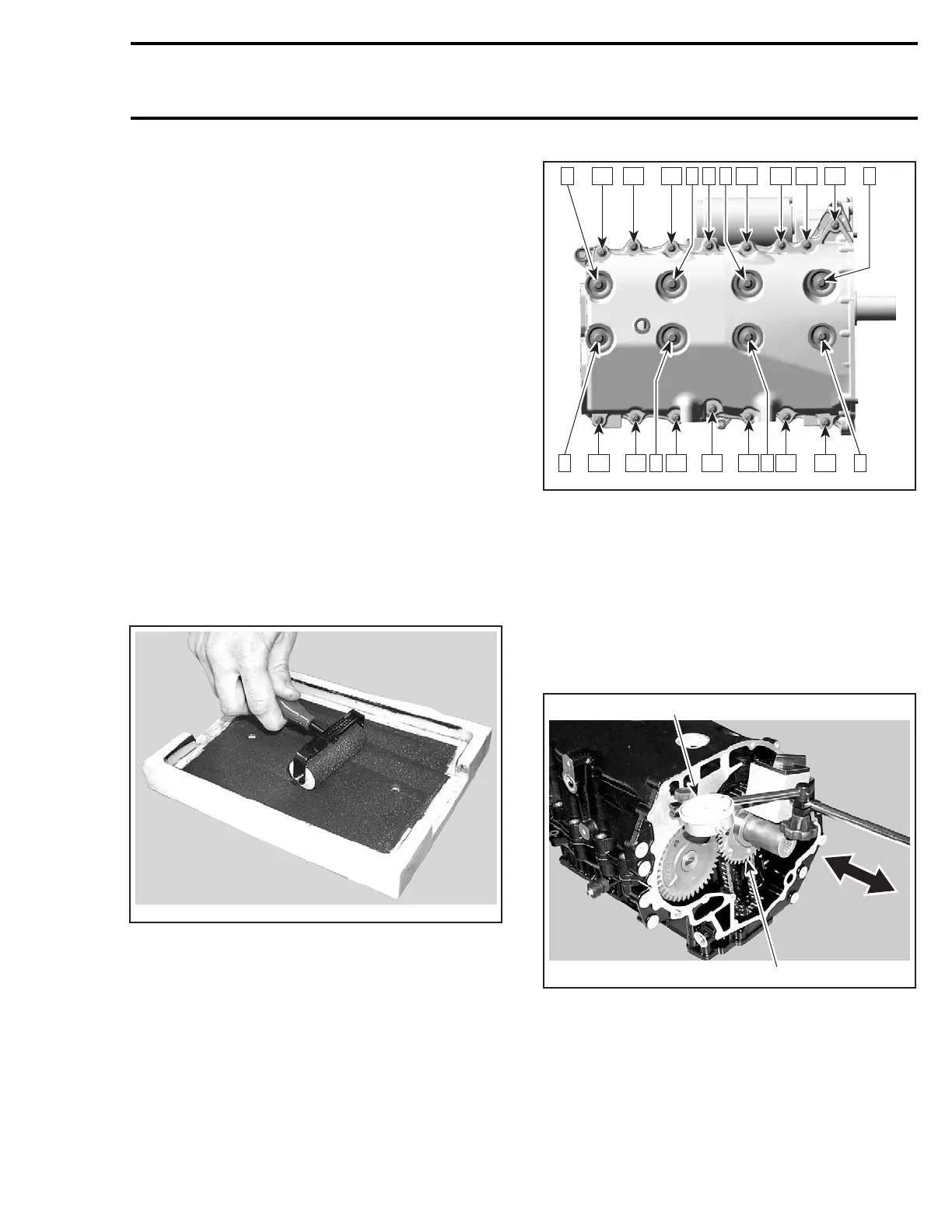

Before continuing the installation process, the ax-

ial clearance of balancer shaft and crankshaft has

to be checked.

1

R1503motr41A

2

1. Dial gauge

2. Crankshaft

smr2004-Complete Line Up 287

Loading...

Loading...