Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

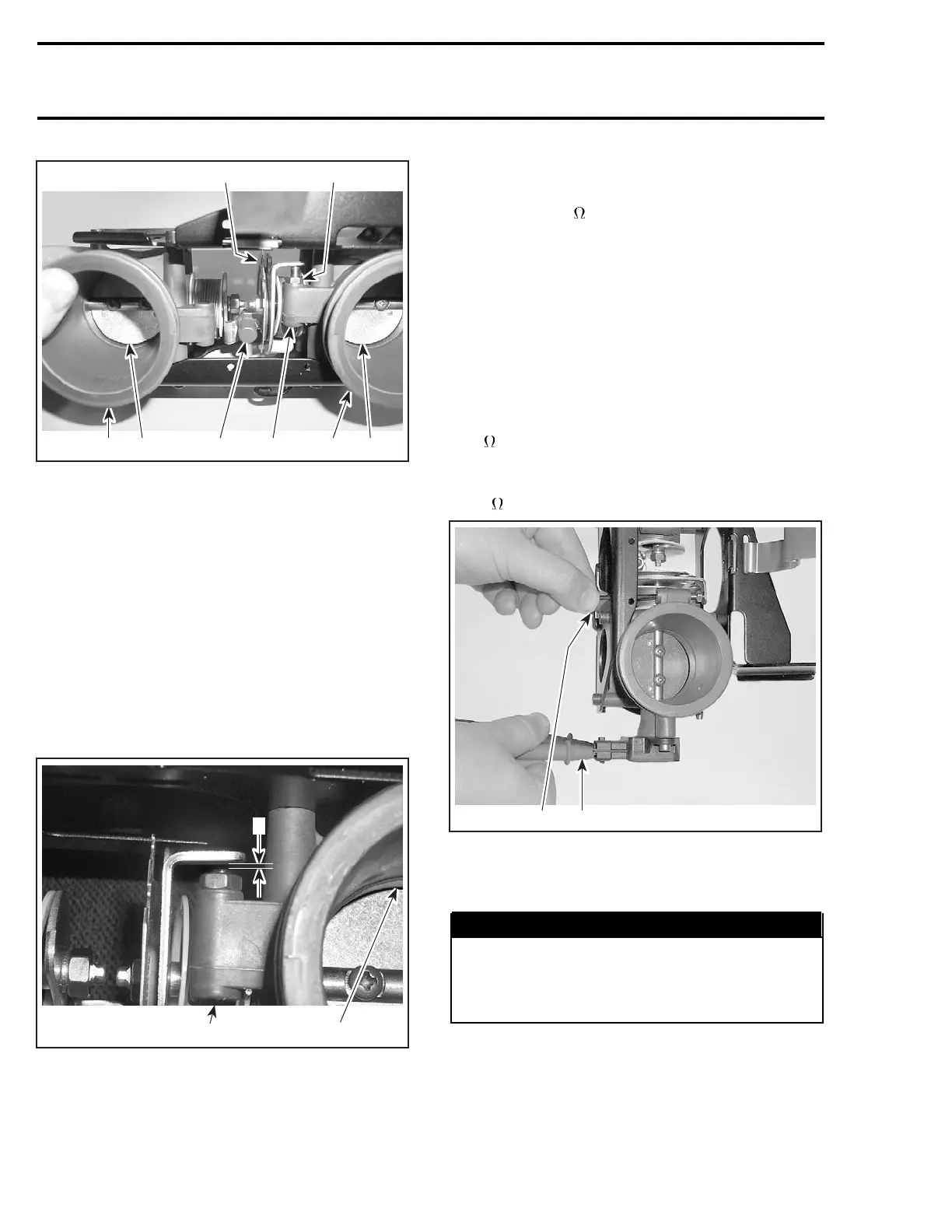

4

F12R0XA

5 8 6 2 3

71

1. Throttle cable attachment

2. Master throttle body

3. Master throttle plate

4. Slave throttle body

5. Slave throttle plate

6. Idle set screw

7. Lock nut

8. Synchronizing screw with its tamper proof cap

NOTE: In the following illustrations, the lower link

plate has been removed for clarity purposes only.

It does not have to be removed to perform the

adjustment.

Loosen lock nut of idle set screw.

Unscrew idle set screw so that master throttle

plate completely closes in the throttle body. En-

sure screw end clears the lever stopper.

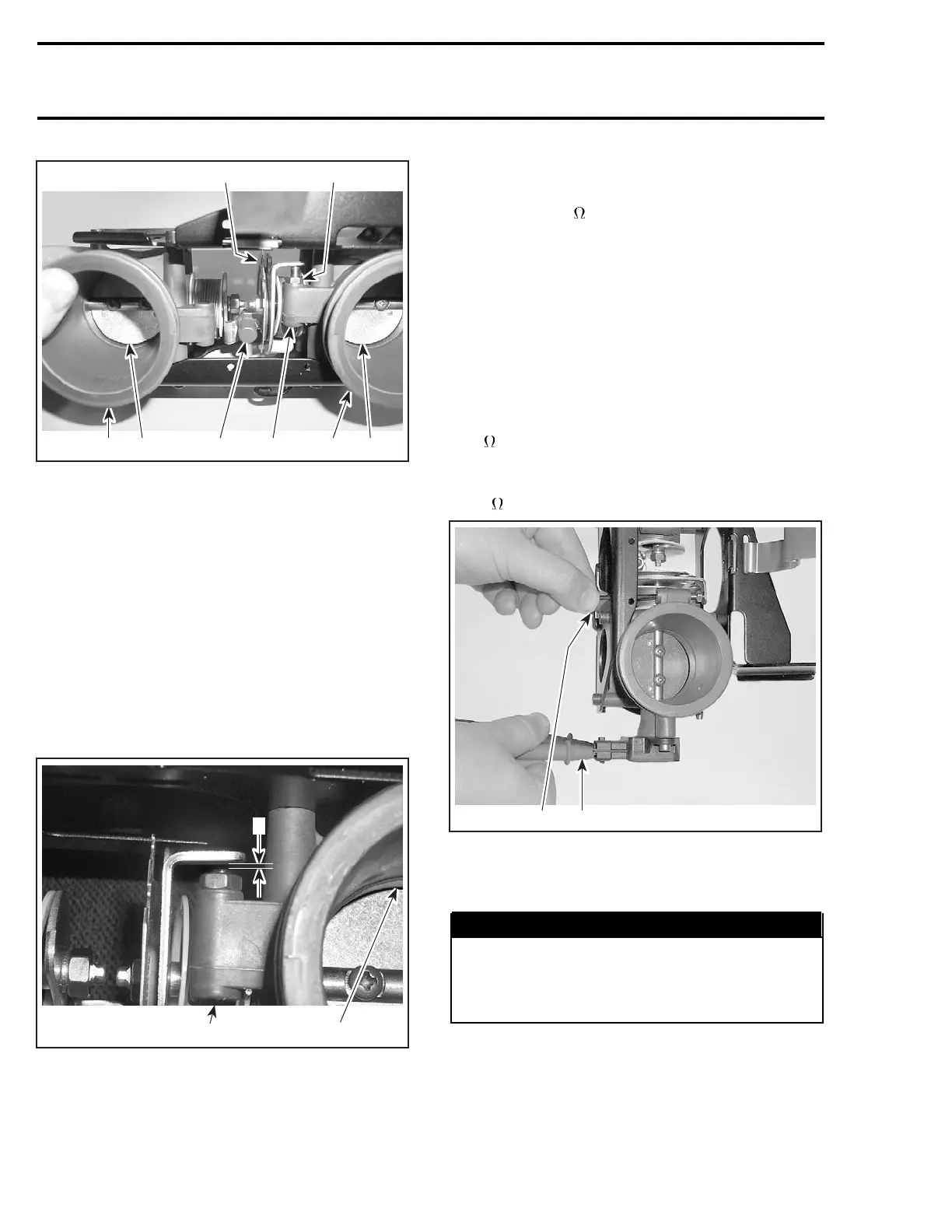

2

F12R0YA

1

3

1. Unscrew until master throttle plate is fully closed in throttle body

2. Unscrew here

3. Gap here

Remove synchronizing screw and spring between

levers.

NOTE: The 175

resistance mentioned below is

used to open the throttle plates the same amount

on each throttle body to obtain the proper synchro-

nization. It is the equivalent of using a drill bit in

the throttle bore to open throttle plate on carbure-

tors.

Master TPS

Snap throttle plate a few times to ensure it is com-

pletely closed.

Using an ohmmeter, measure resistance between

terminals 2 and 3. Note the resistance value. Add

175

to that value.

Turn idle set screw clockwise until ohmme-

ter reading reaches the computed value above

±20

.

F12R1BA

12

1. Measure resistance between terminals 2 and 3

2. Turn screw clockwise to

increase resistance

Tighten lock nut.

WARNING

Do not apply any threadlocker on the screw

threads. The threadlocker may leak off the

screw and onto the throttle mechanism and

cause the throttle to stick.

Recheck reading and readjust as necessary.

340 smr2004-Complete Line Up

Loading...

Loading...