Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Slave TPS

Install a new synchronizing screw. Screw in and

ensure screw end clears the lever stopper. En-

sure also to keep slave throttle plate completely

closed in the throttle body.

WARNING

Ensure to use a new screw which is coated

with the proper threadlocker to avoid further

loosening. Do not use the removed screw

even if you were applying any threadlocker.

The threadlocker may leak off the screw and

flow onto the throttle mechanism and cause

the throttle to stick.

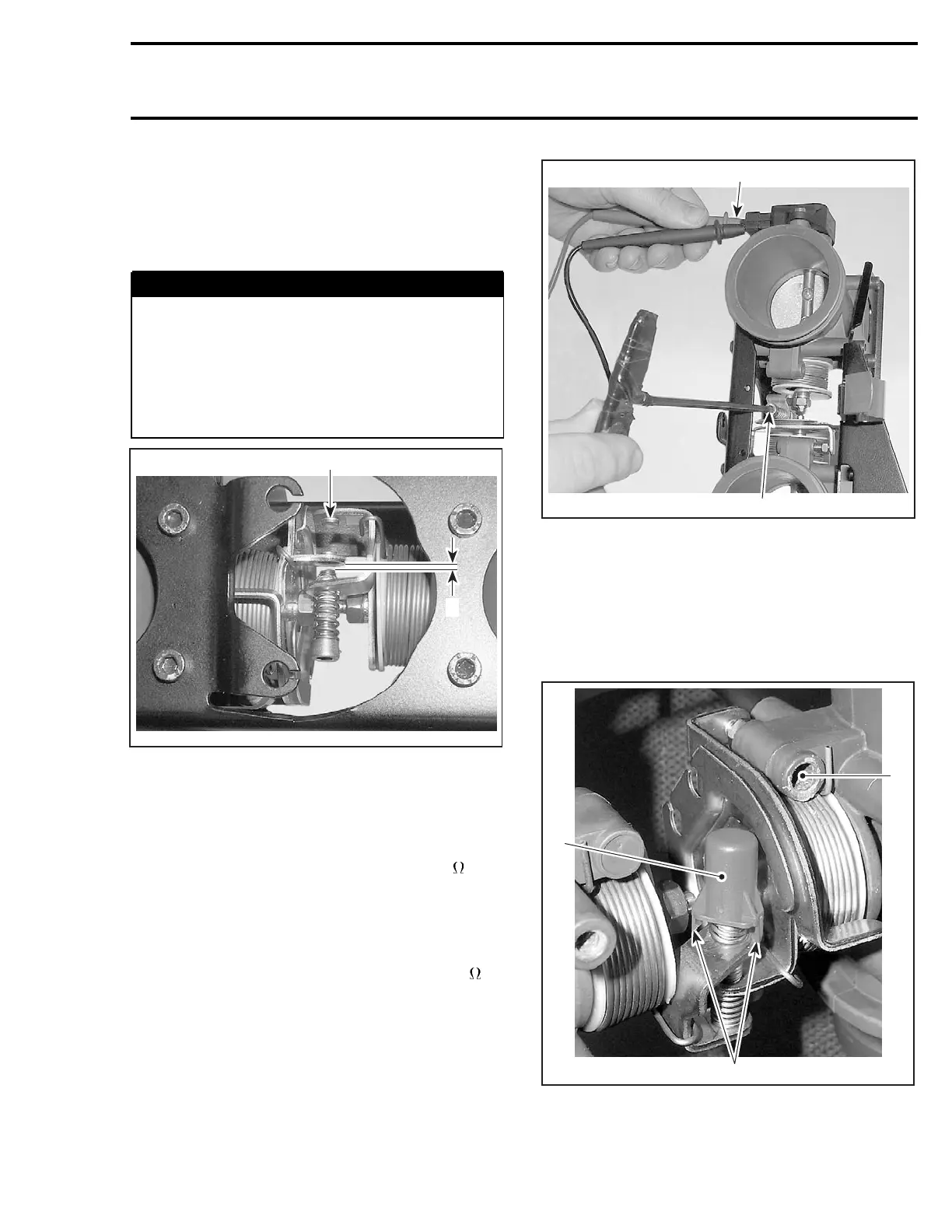

2

F12R1DA

1

1. Gap here

2. Spring removed

Snap throttle plate a few times to ensure it is com-

pletely closed.

Measure resistance between terminals 2 and 3.

Note the resistance value. Substract 175

from

that value.

Properly reinstall the spring. Ensure that master

throttle plate is still closed.

Turn synchronizing screw clockwise until read-

ing reaches the computed value above ± 20

.

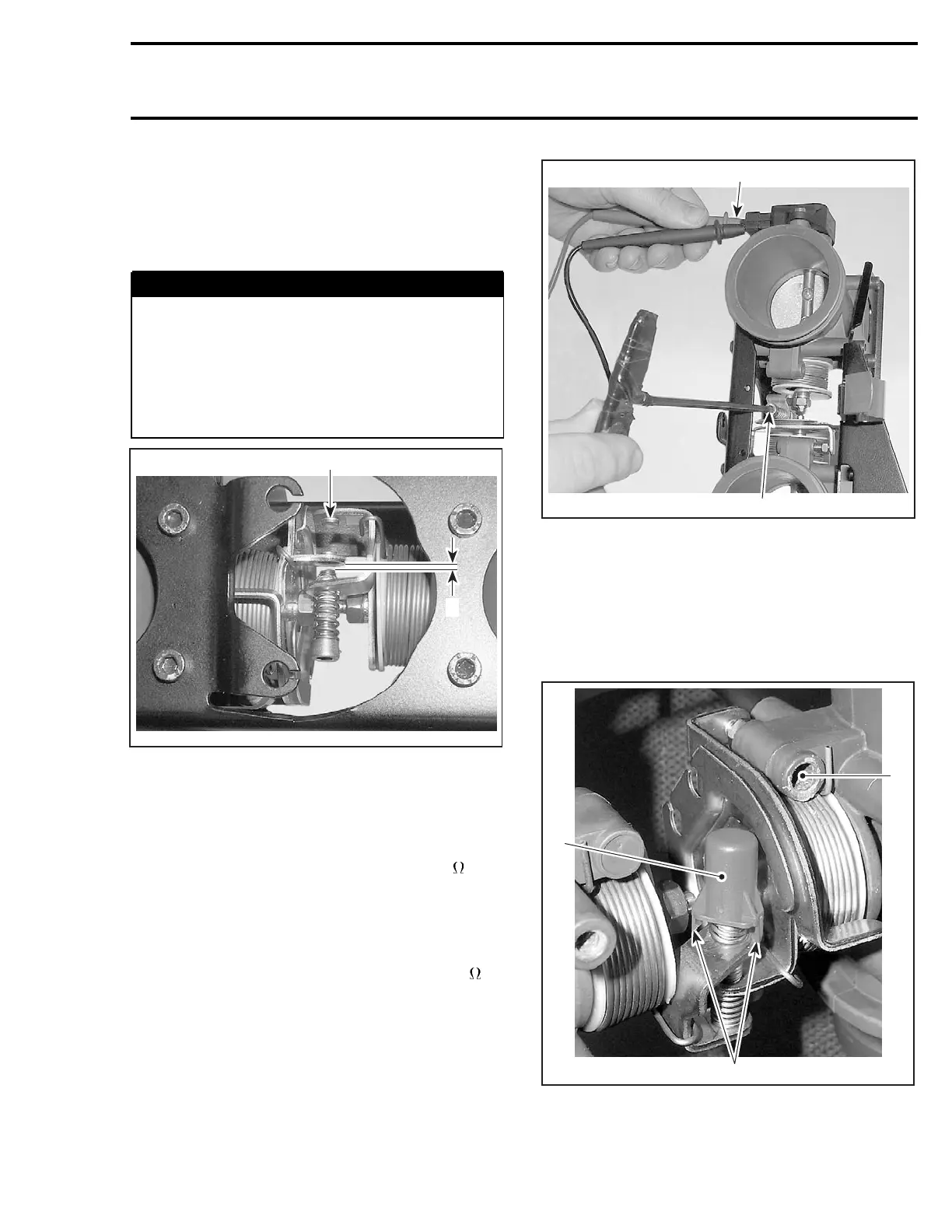

1

2

F12R1CA

1. Measure resistance between terminals 2 and 3

2. Turn screw clockwise to

decrease resistance

Ensure spring is still well positioned on stoppers.

Properly reinstall the plastic cap on the synchro-

nization screw.

Apply Loctite 5900 (P/N 293 800 066) RTV silicone

sealant on idle set screw head.

1

F12R10A

3

2

1. Plastic cap

2. Wider spaced tabs here

3. Loctite5900flangesealant

smr2004-Complete Line Up 341

Loading...

Loading...