Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Adjustment

In this operation, the ignition timing light and

B.U.D.S. are used to synchronize the MPEM TDC

reference with the engine crankshaft. This timing

adjustment will affect the timing of ignition as

well as direct injector timings. The aim of the

adjustment is to align the mark on the flywheel

with the pointer at idle using the timing light and

B.U.D.S. When this is achieved, then the MPEM

TDC reference is synchronized with the engine

crankshaft.

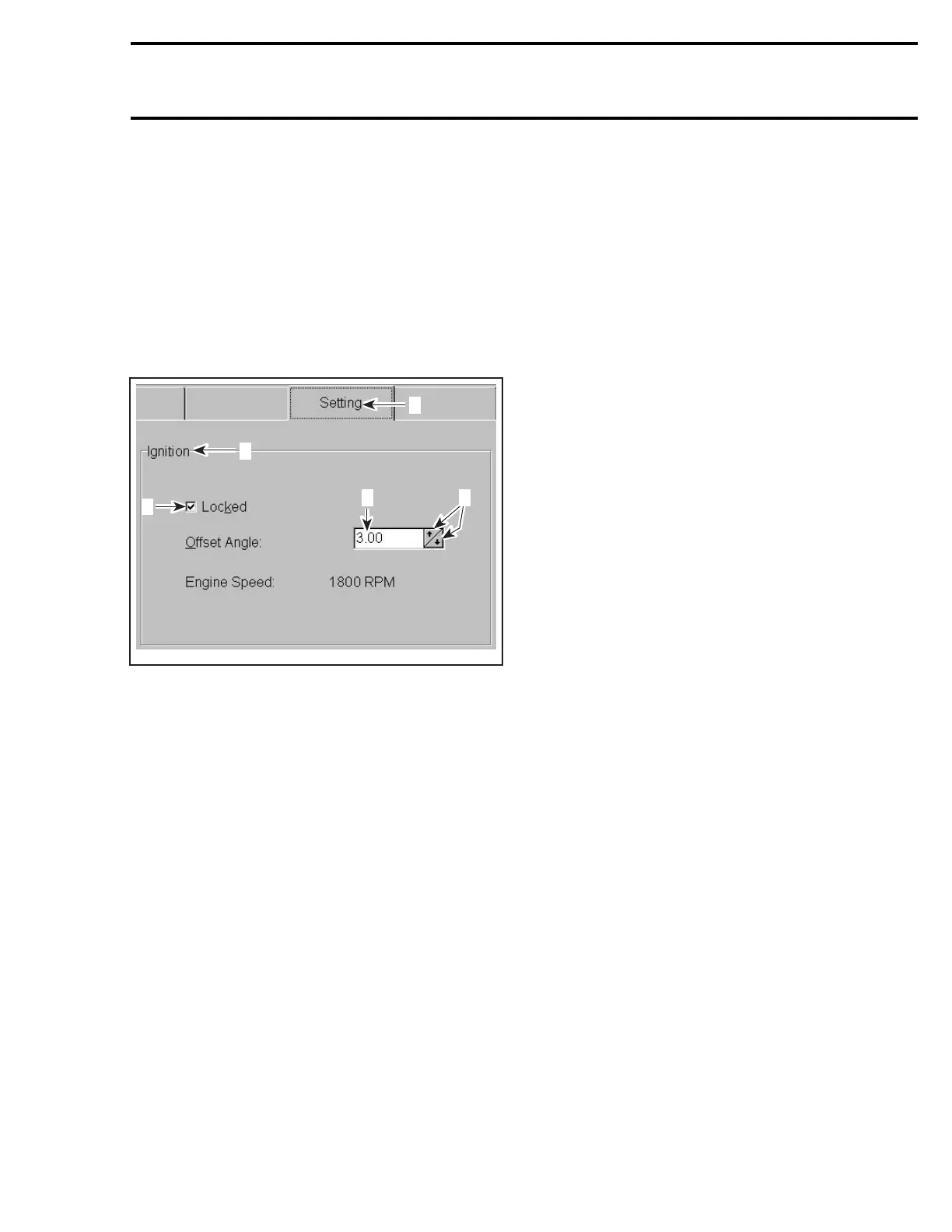

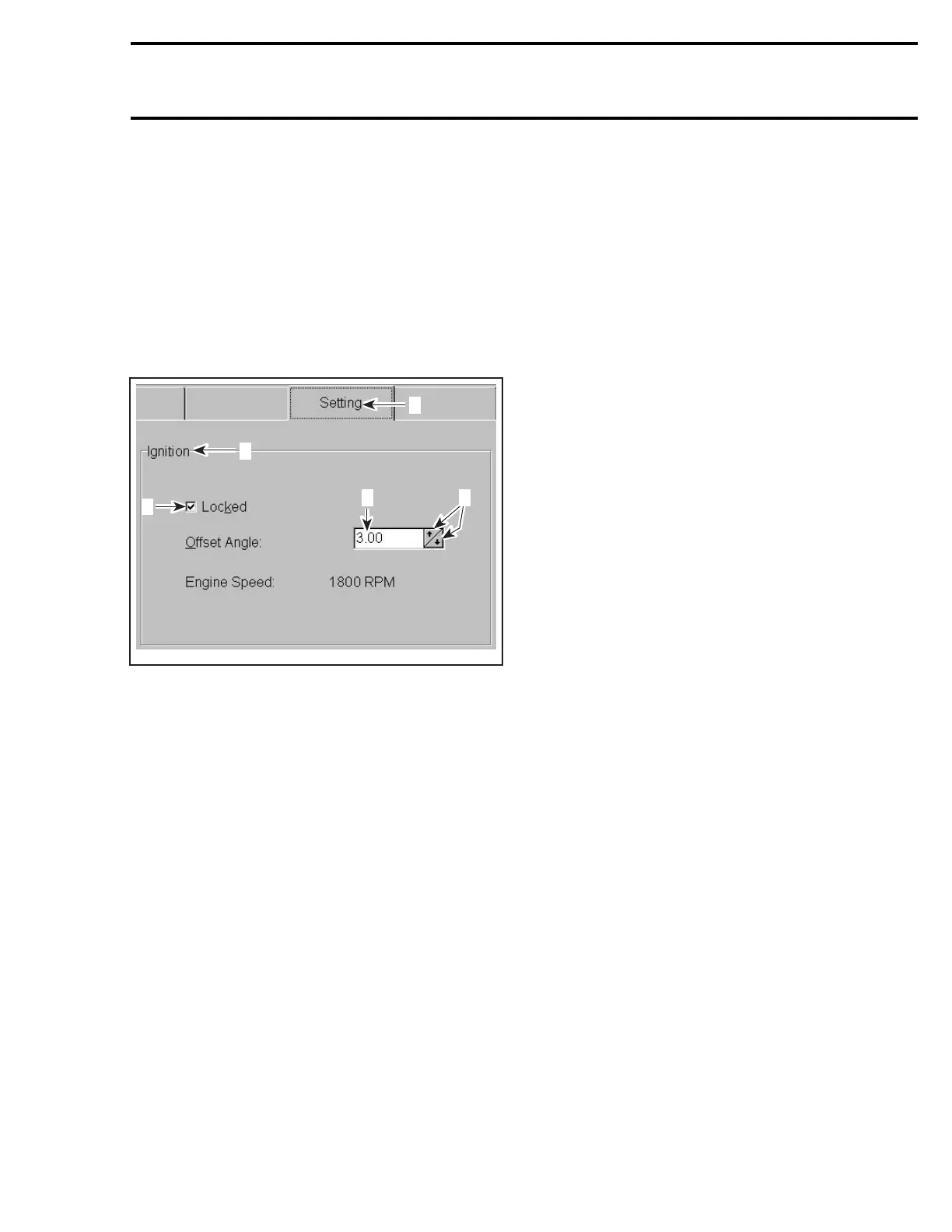

F17H08A

1

2

3

4 5

1. “Setting” tab

2. Ignition section

3. “Locked” box

4. Current angle in MPEM

5. Arrows to change the angle

– Choose the Setting tab and look under Ignition.

– Check the Locked box to “freeze” the timing at

the correct value.

– The VCK displays the number that is stored in

the MPEM.

– Nowclicktheupordownarrowtochangethe

number of the current angle so that the set-

ting marks align when checking with the timing

light. Each step makes an adjustment of 1/4 de-

gree.

NOTE: Each time the setting is changed on the

screen, the new value is also changed in the

MPEM, so there may be a slow response, do not

make changes too quickly.

– When marks align, uncheck the Locked box to

finish.

NOTE: This will write the new value immediately

in the MPEM. There is no need to press the “Write

data” button to transfer the data to the MPEM un-

less other changes were made. However, we rec-

ommend to reset the service hours when you per-

form a service action such as the ignition timing

setting.

NOTE: The MPEM features a permanent (non-

volatile) memory and keeps the ignition timing set-

ting programmed even when the watercraft bat-

tery is disconnected.

Engine Start/Stop Switch Verification

A quick operation test can be done using the ve-

hicle communication kit (VCK) with the B.U.D.S.

software, using the MONITORING section. Press

the start button and look at the Start button LED.

It should turn on, indicating the starting system

isworkingontheinputside(startbutton,MPEM

and wiring). You know now the problem is on the

output side (MPEM output signal to starting sole-

noid, wiring harness going to the solenoid, starter

motor. Refer to STARTING SYSTEM for testing

procedures). Otherwise, check the input side as

follows.

Disconnect the YELLOW/RED wire of the start/

stop switch. Using an ohmmeter, connect test

probes to YELLOW/RED wire and to ground.

Measure resistance, it must be an open circuit

(switch is normally open). Depress and hold

switch, the ohmmeter should read close to

0 ohm. Otherwise, replace switch.

If the switch tests good, check continuity of cir-

cuits 2-8 and 2-12 using a multimeter.

If wiring harness tests good, it could be the

MPEM. Try a new MPEM referring to MPEM

REPLACEMENT procedures elsewhere in this

section.

Safety Lanyard Switch Verification

If 2 short beeps are not heard when installing

the safety lanyard, refer to DIAGNOSTIC PROCE-

DURES.

The following continuity tests can also be per-

formed using an ohmmeter:

Disconnect switch wires.

smr2004-Complete Line Up 371

Loading...

Loading...