Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

NOTE: This specification is of the type “indirect

measurement” relative to the piston movement

since we are measuring at a 45° angle through the

spark plug hole.

– Scribe a thin mark on PTO flywheel aligned with

timing mark pointer tool.

NOTE: This mark becomes the reference when

using the stroboscopic timing light.

CAUTION: The static test cannot be used as an

ignition timing setting verification, therefore,

always check the ignition timing setting with a

stroboscopic timing light.

– Remove TDC gauge.

– Reinstall spark plug and connect wire.

Dynamic Test

To check ignition timing setting, use a timing light

(available at local facilities).

NOTE: Ensure to use a timing light capable to

work with – stroke engines.

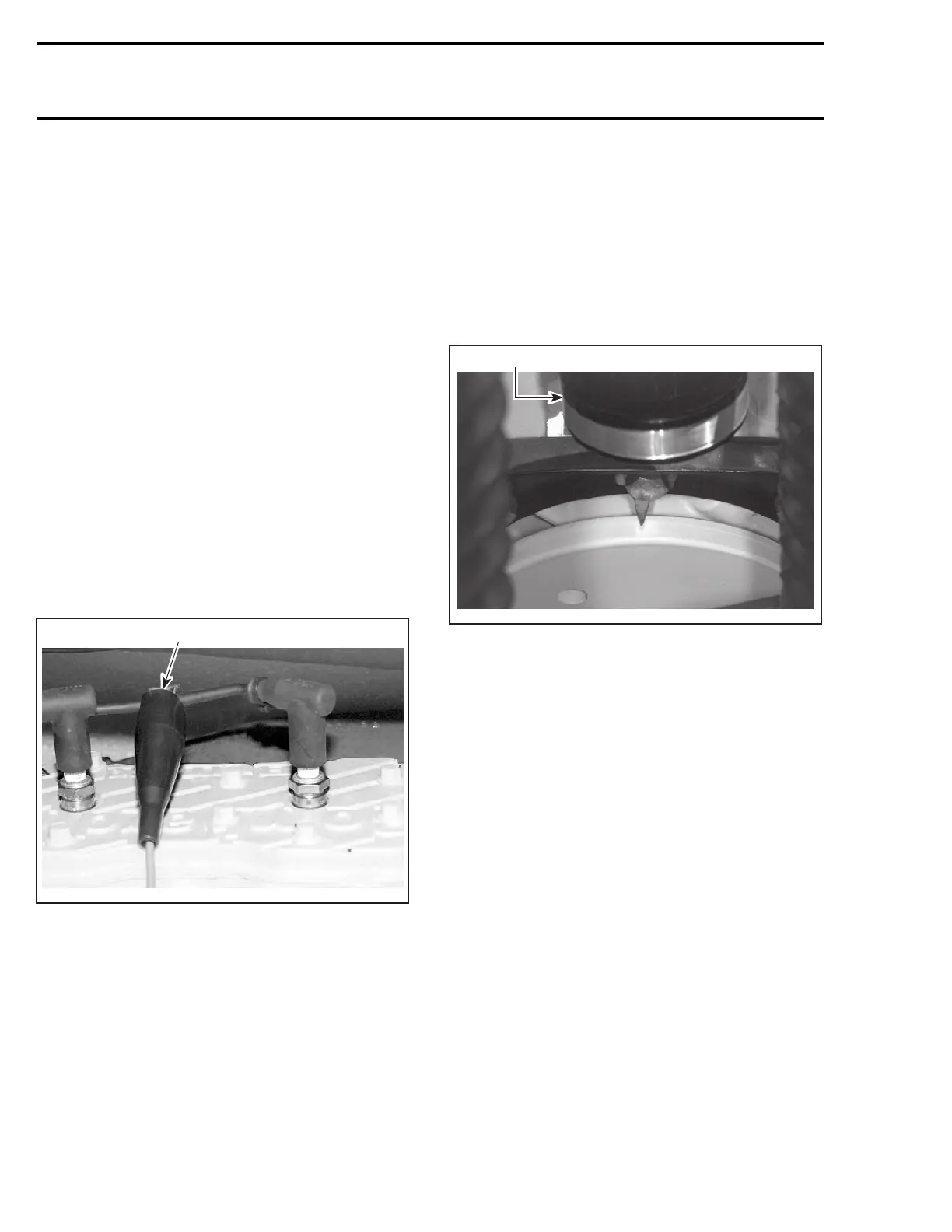

– Connect timing light pick-up to MAG side spark

plug wire.

1

F00H1QA

TYPICAL

1. Timing light pick-up

IMPORTANT: To check the ignition timing setting,

the spark advance curve must be locked first. This

allows to verify ignition timing setting at any RPM

by keeping the ignition timing “frozen” so that it

does not vary with engine RPM. See IGNTION

TIMING ADJUSTMENT below for more informa-

tion.

CAUTION: If the spark advance curve is not

locked using B.U.D.S. then a wrong ignition

timing will be seen as the ignition curve does

not match the locked ignition timing.

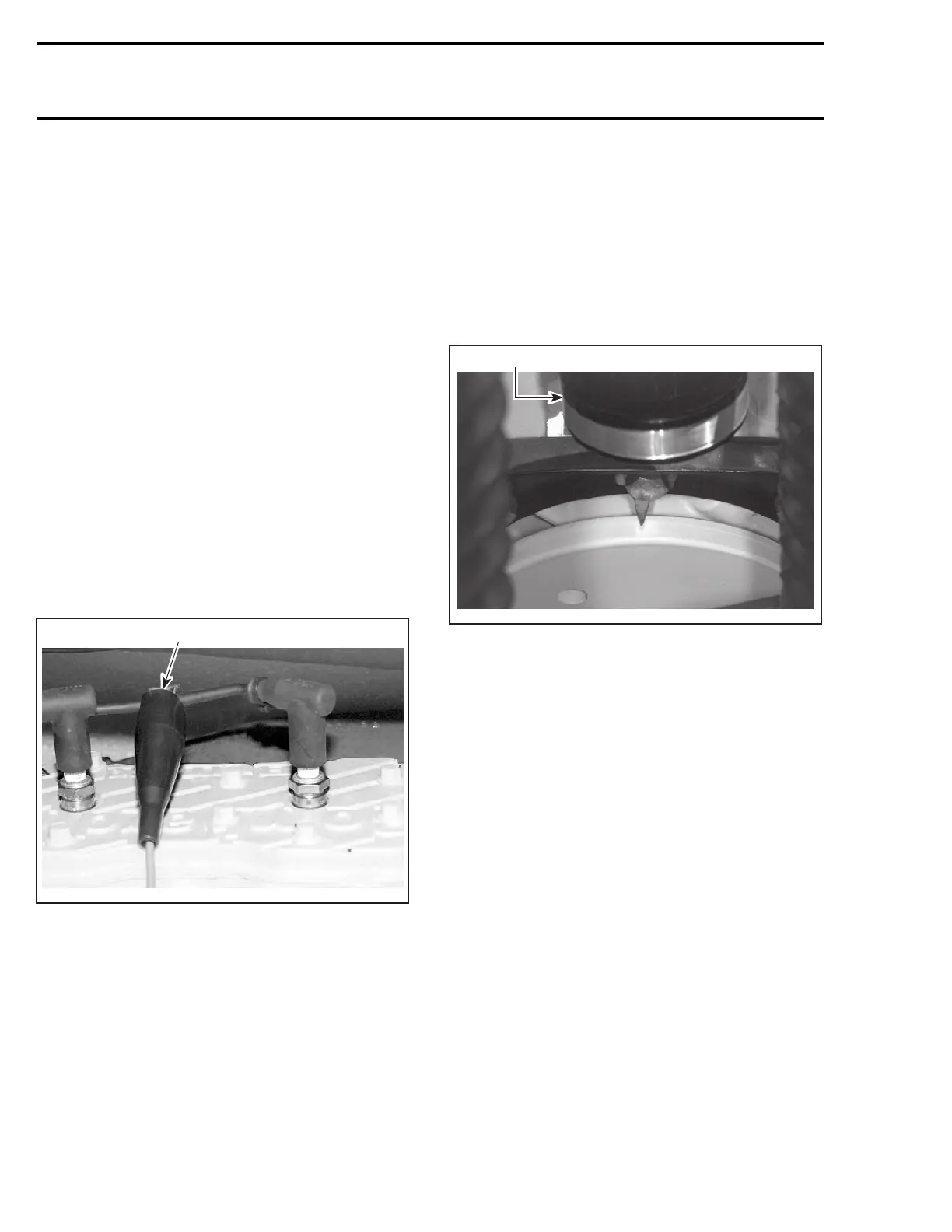

– Start engine and check mark at idle speed.

Point beam of timing light straight in line with

timing mark pointer.

NOTE: Look at the mark at the same angle as it

was scribed so that parallax error is minimized.

F06H07A

1

1. Timing light straight in line with pointer

CAUTION: If engine is to be run more than a

few seconds, engine must be cooled using the

flush kit.

NOTE: If mark on PTO flywheel is perfectly

aligned with timing mark pointer, no adjustment

is required. If mark does not align with pointer,

recheck PTO flywheel mark before changing the

ignition timing setting to ensure PTO flywheel has

not loosen or tightened.

Ignition Timing Adjustment

General

To correct the ignition timing setting, the data

oftheMPEMischangedusingtheVCK(Vehicle

Communication Kit) (P/N 295 035 981). Look in

Setting tab of the software B.U.D.S.

NOTE: For more information on the VCK, refer to

its online help. The MPEM programmer will not

work to perform this operation on the DI engines.

CAUTION: If the ignition timing setting is ad-

justed too advanced, this will cause serious

damage to the engine.

370 smr2004-Complete Line Up

Loading...

Loading...