Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Mechanical Inspection

Check that the throttle plate moves freely and

smoothly when depressing throttle lever. Take

this opportunity to lubricate the throttle cable.

IMPORTANT: The throttle body is designed to be

tamper proof. Changing the idle stop or modify-

ing it in any way will not increase performance or

change the idle speed but may cause poor starta-

bility and erratic idling.

Before replacing any part, check the following as

these could be causing the fault. Perform the test

while the engine is not running.

– Throttle cable adjustment too tight. Not return-

ing fully to idle stop.

– Throttle body idle set screw is loose or worn.

– TPS is loose.

– Idle bypass valve is loose.

– Corroded or damaged wiring or connectors.

– Throttle body has been replaced and the Closed

Throttle and Idle Actuator reset has not been

performed.

– ECM has been replaced and the Closed Throt-

tle and Idle Actuator reset has not been per-

formed.

Electrical Inspection

Refer to THROTTLE POSITION SENSOR (TPS)

and IDLE BYPASS VALVE in ELECTRONIC MAN-

AGEMENT below.

To verify the engine RPM with tachometer

(P/N 529 014 500), use the following proce-

dure.

The inductive tachometer works on these ignition

coils (stick coils) as well as on regular high tension

coil. Simply wrap the tachometer's wire a few

times around the protruding part of ignition coil.

A32CCIA

TYPICAL

Replacement

Removal

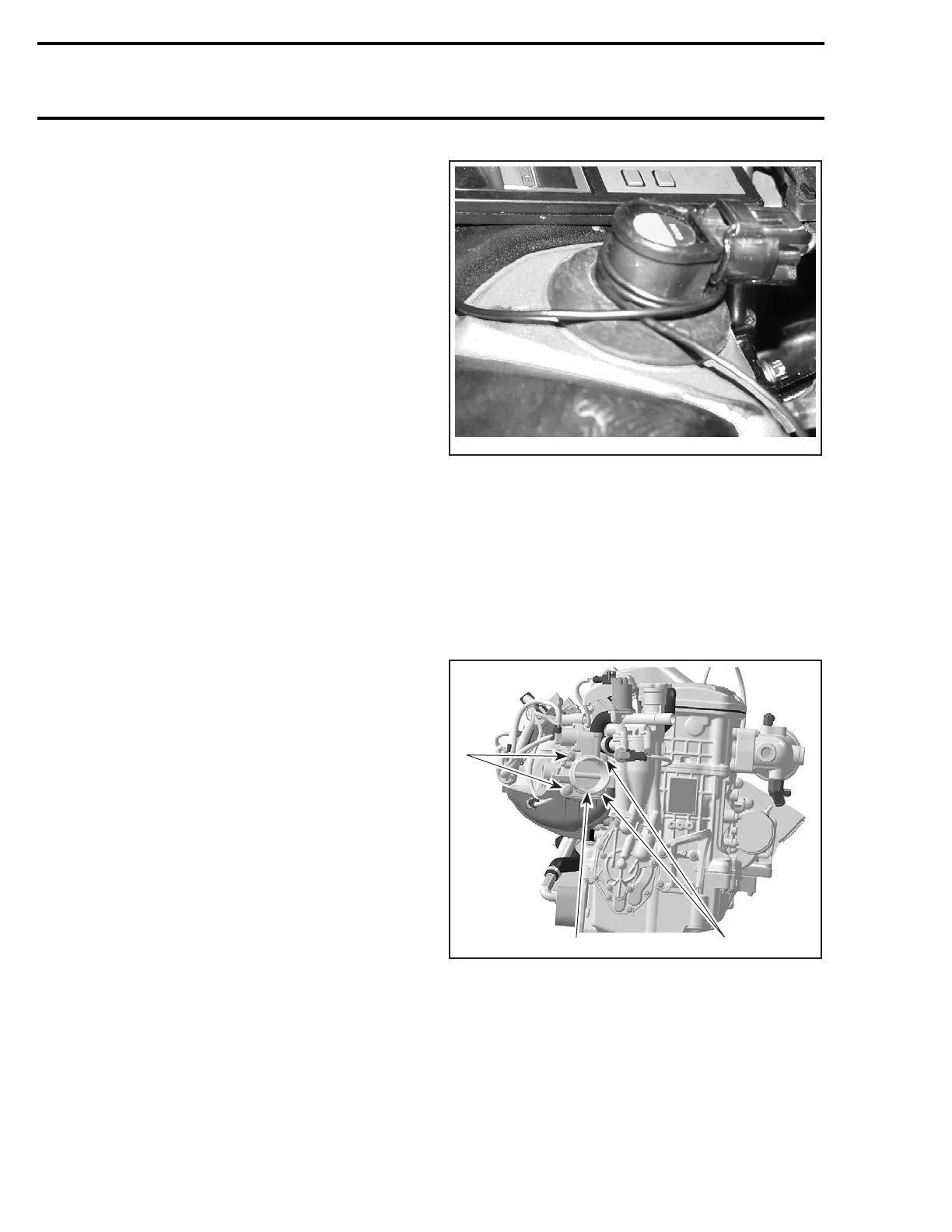

To remove the throttle body from engine, proceed

as follows:

– Disconnect air intake silencer from throttle

body. Move boot away.

– Remove retaining screws of throttle body.

R1503motr205A

2

2

1

4-TEC NATURALLY-ASPIRATED MODELS

1. Throttle body

2. Screws

408 smr2004-Complete Line Up

Loading...

Loading...