Section12ELECTRICALSYSTEM

Subsection 01 (IGNITION SYSTEM)

90

80

70

60

50

40

30

20

10

0

1

F01H4LA

TYPICAL

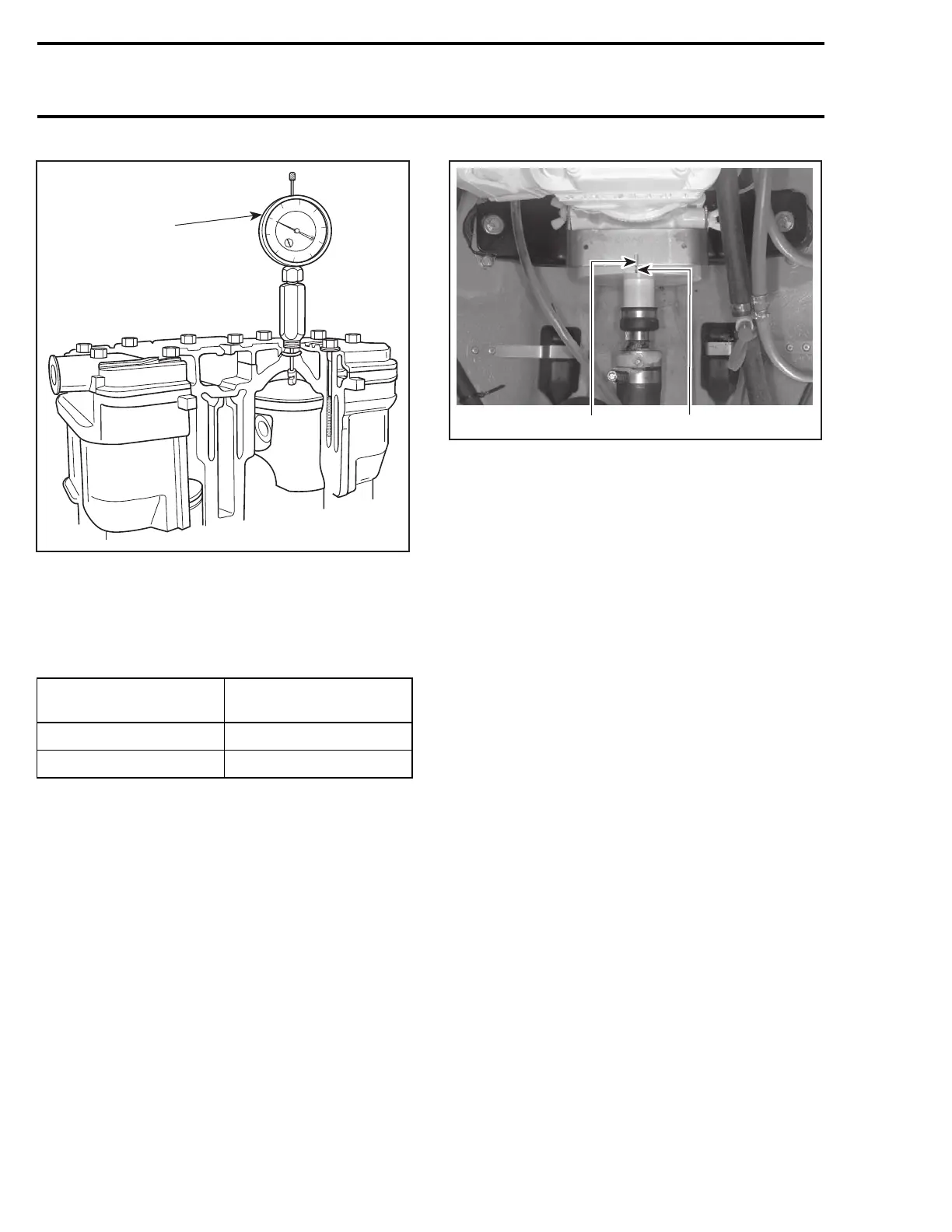

1. Adjust gauge dial at zero

– From this point, rotate flywheel clockwise to

reach proper specification according to engine.

Refer to the following chart.

ENGINE IGNITION TIMING

(BTDC)

717

2.59 mm (.102 in)

787 RFI 1.02 mm (.040 in)

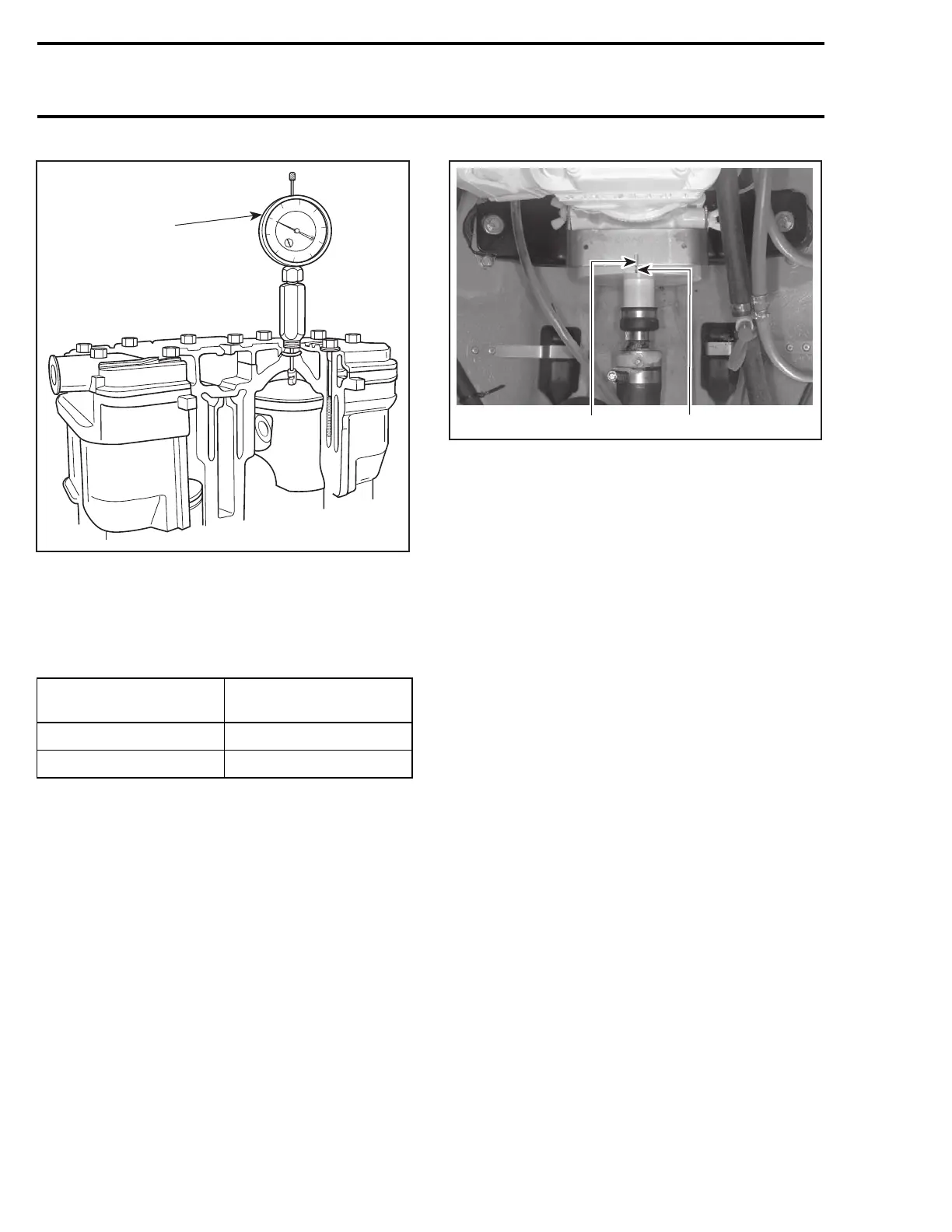

– Scribe a thin mark on PTO flywheel in the mid-

dle of tool slot (717 engines) or aligned with tim-

ing mark pointer tool (787 RFI engines).

F01H5SB

1

2

TYPICAL

1. Tool slot

2. Flywheel mark

NOTE: This mark becomes the reference when

using the stroboscopic timing light.

CAUTION: The static test cannot be used as a

timing procedure, therefore, always check the

timing with a stroboscopic timing light.

– Remove TDC gauge.

– Reinstall spark plug and connect wire.

Dynamic Test

To check ignition timing, use a timing light (avail-

able at local facilities).

NOTE: Ensure to use a timing light capable to

work with 2-stroke engines.

717 Engines

NOTE: To perform this procedure, make sure to

useastroboscopictiminglightratedupto6000

RPM. Otherwise, an inaccurate reading will be ob-

tained.

The ignition components are affected by tempera-

ture variation, therefore, timing must be checked

when engine is cold, after idling for a MAXIMUM

of 20 seconds.

– Connect an induction-type tachometer

(P/N 529 014 500) to spark plug wire.

546 smr2004-Complete Line Up

Loading...

Loading...