Section 04 ENGINE (2-STROKE)

Subsection 01 (LEAK TEST)

NOTE: Engines with the RAVE system, the boot

(carburetor-equipped engines) and O-ring can be

checked for leakage with the valve in place. Sim-

ply remove the cover to expose the parts.

Make sure the spark plugs (and the air/fuel rail on

DI engine) are installed and tightened.

Block pulse hose (carburetor-equipped engines)

using a hose pincher.

NOTE: Do not block the rotary valve shaft hoses

(if so equipped).

Install pump to the exhaust plate fitting.

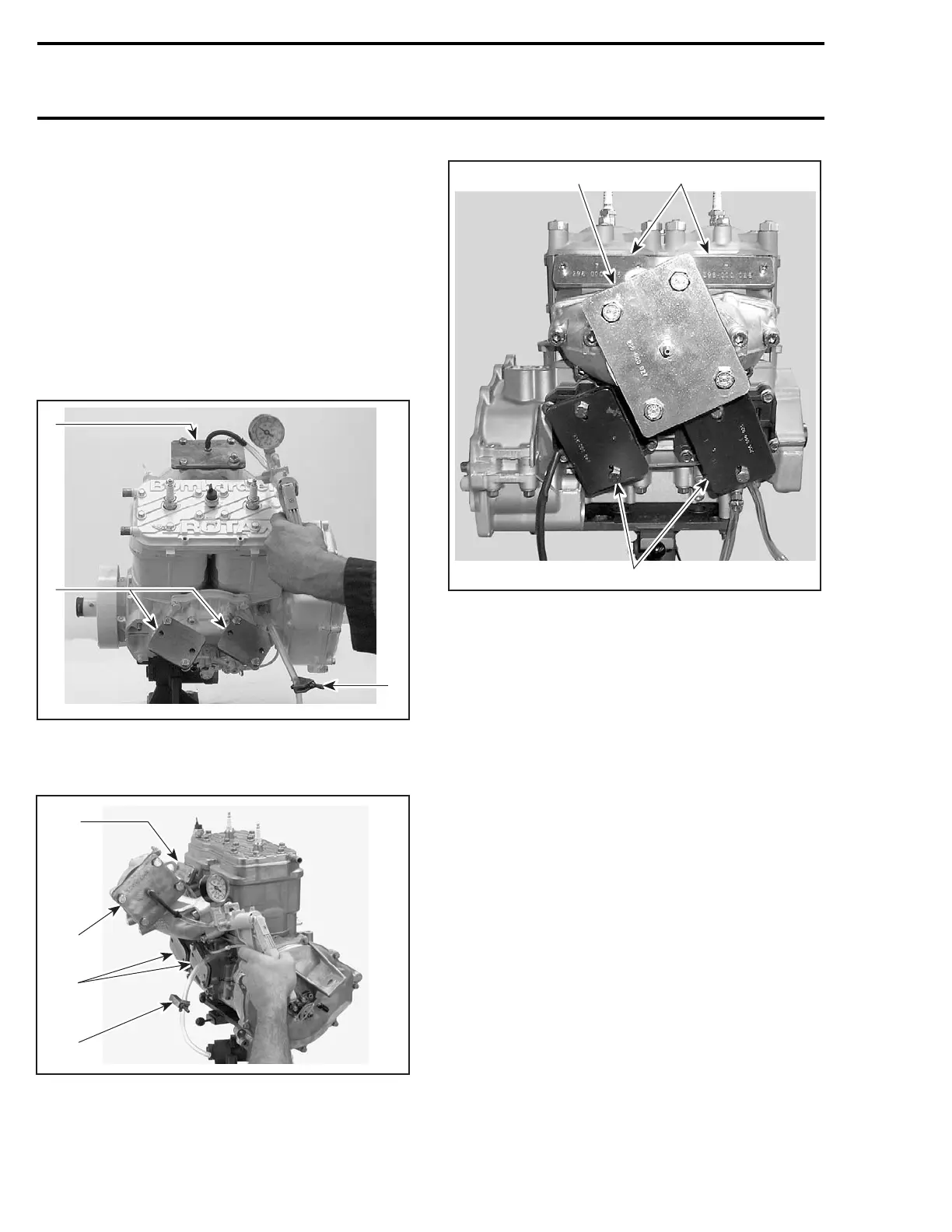

F01B2ZA

2

3

1

717 ENGINES

1. Intake plates

2. Pulse hose blocked with a hose pincher

3. Exhaust plate

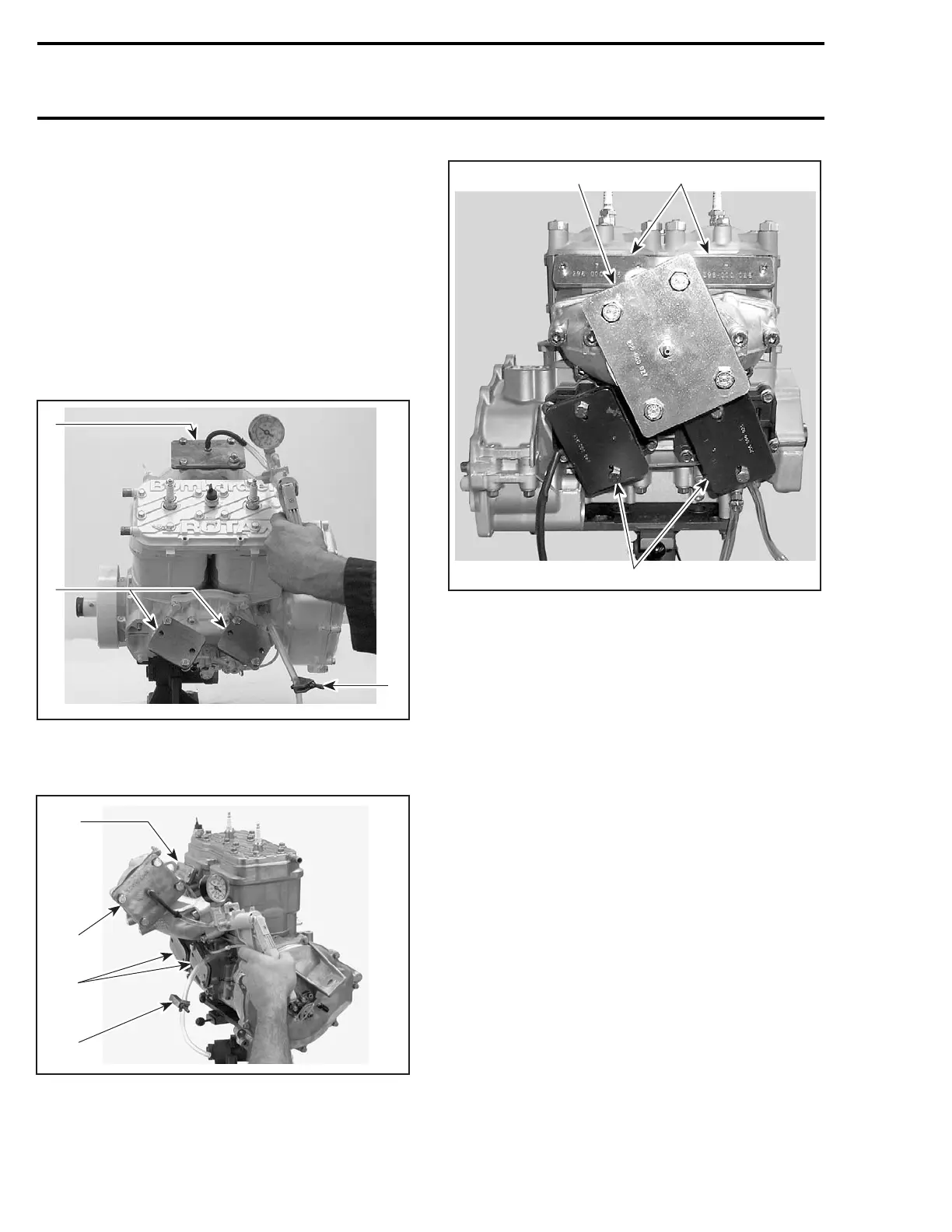

F01B30A

2

4

1

3

787 RFI ENGINES

1. Intake plates

2. RAVE valve plates

3. Pulse hose blocked with a hose pincher

4. Exhaust plate

3

12

F08D05A

947 DI ENGINES

1. Exhaust plate

2. Rave valve plates

3. Intake plates

Activate pump and pressurize engine to 34 kPa

(5 PSI).

CAUTION: Do not exceed this pressure.

Wait 3 minutes and check if pressure drops; if so,

verify all testing components.

If kit components are not leaking, verify engine

jointed surfaces as per following areas:

– spark plugs

– direct injector sealing (DI engines)

– cylinder head gasket

– cylinder base gasket

– crankcase halves

– rotary valve cover (except DI engines)

– engine plugs

– exhaust manifold

– intake manifold (717 engines)

– intake flanges (DI engines)

– oil injection pump (717 engines).

Check also small oil injection pump lines and fit-

tings; check for air bubbles or oil column going

toward pump, which indicate a defective check

valve.

66 smr2004-Complete Line Up

Loading...

Loading...