Section 04 ENGINE (2-STROKE)

Subsection 01 (LEAK TEST)

Check for leak through counterbalancing shaft seal

toward air compressor (DI engines). Air bubbles in

lowest fitting (oil return line) underneath compres-

sor indicates a seal leakage.

If the above mentioned components are not leak-

ing, block both oil hoses of the rotary valve shaft

(if so equipped) using hose pinchers.

NOTE: If leakage stops at this point, proceed with

ROTARY VALVE SHAFT testing (if so equipped).

If there is still some leakage, remove the PTO fly-

wheel to verify outer seal.

If no leak is found on the PTO side outer seal,

remove magneto flywheel and verify crankshaft

outer seals.

ProceedwiththeROTARYVALVESHAFTtesting

(if so equipped) if the crankshaft outer seals are

not leaking.

Rotary Valve Shaft (if so equipped)

NOTE: It is mandatory to drain the injection oil

from the rotary valve shaft.

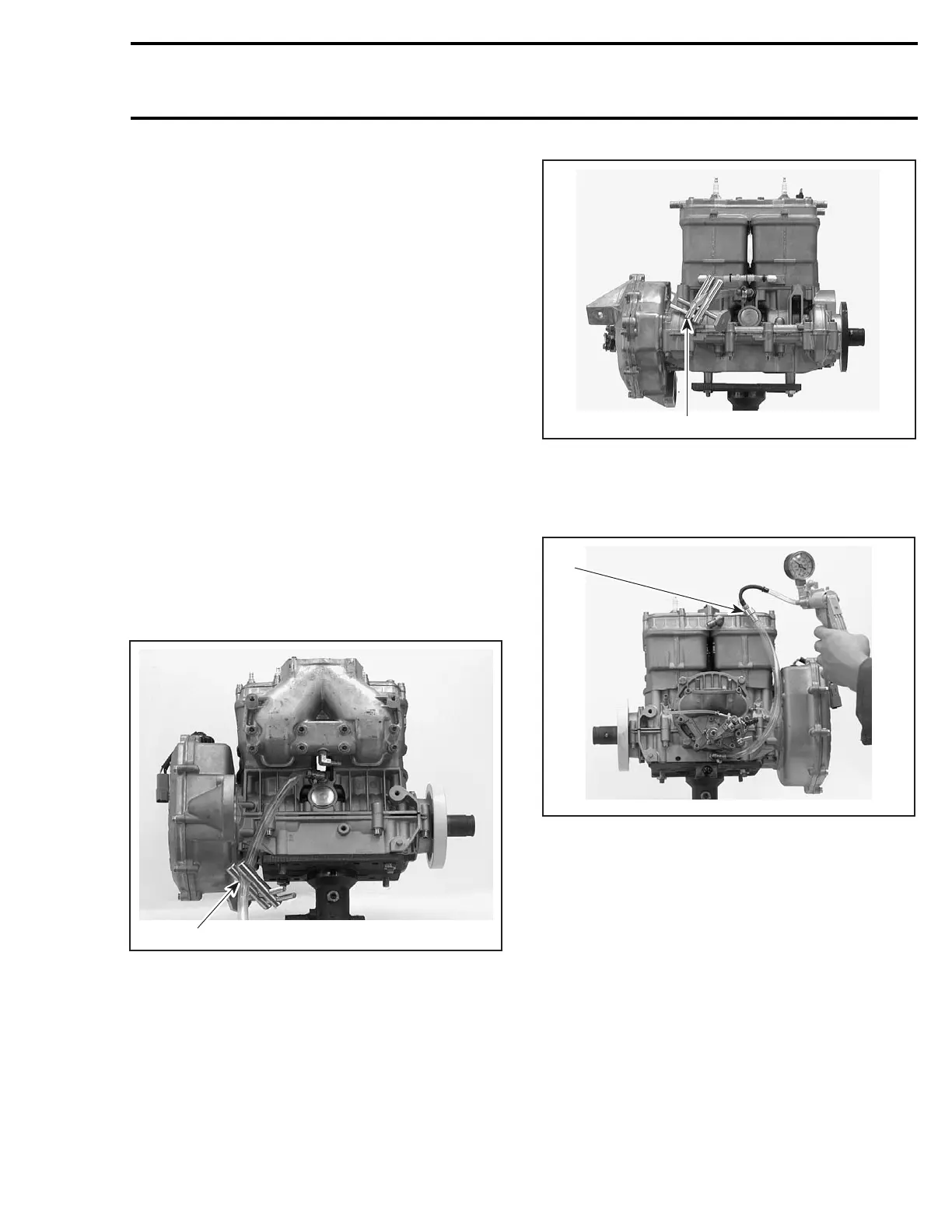

Block oil return hose of the rotary valve shaft with

ahosepincher.

F01B31A

1

717 ENGINES

1. Oil return hose blocked with hose pincher

F01B33A

1

787 RFI ENGINES

1. Oil return hose blocked with hose pincher

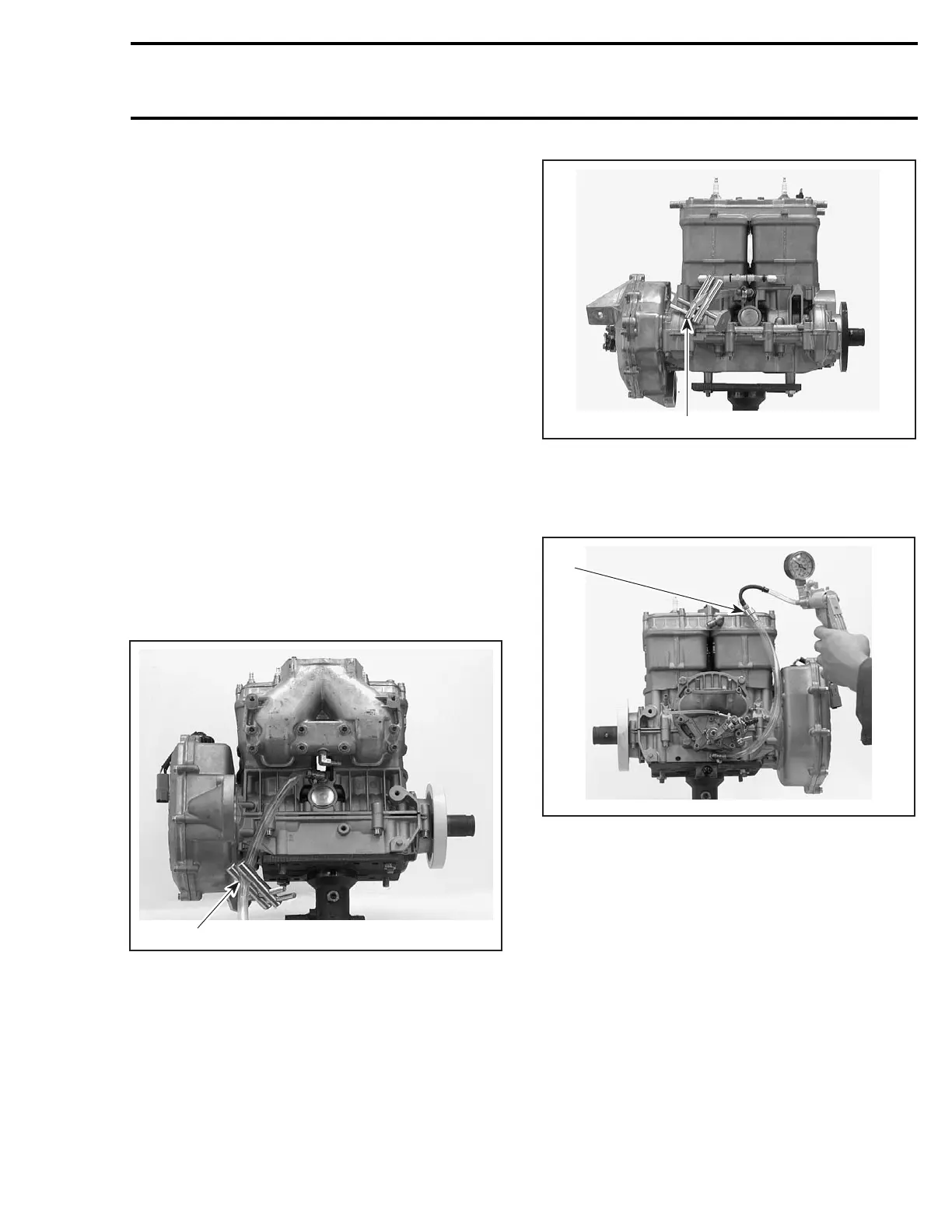

Install pump with reducer and nipple to the oil sup-

ply hose of the rotary valve shaft.

F01B32A

1

717 ENGINES

1. Pump with reducer and nipple

smr2004-Complete Line Up 67

Loading...

Loading...