TOMATECH AUTOMATION

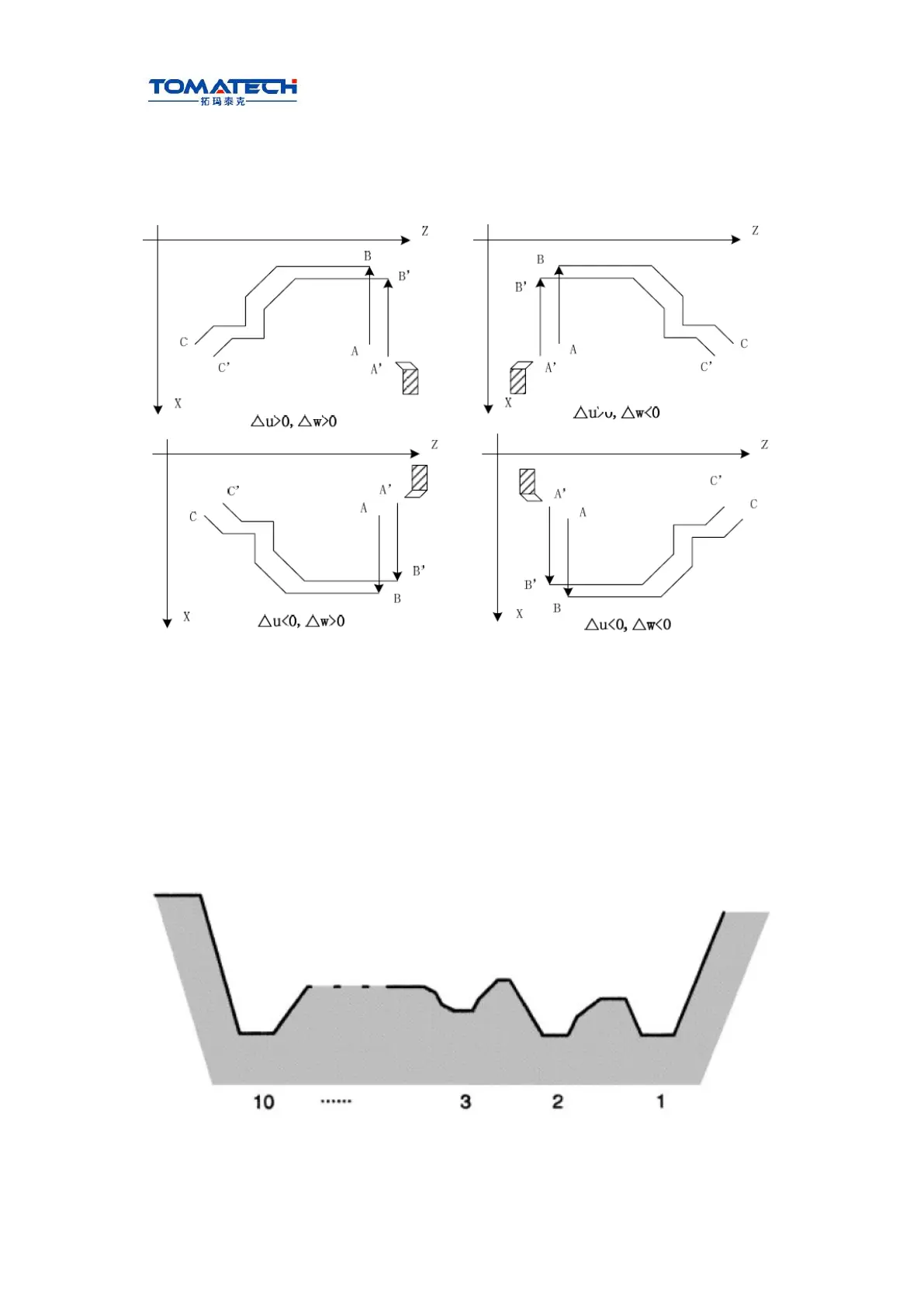

2)Coordinate offset direction with finishing allowance:

Δu, Δw define the coordinate offset and cut-in direction in finishing, and their sign symbol

are as follows Fig. 3-26: B→C for finishing path, B’→C’ for roughing path and A is the tool

start-up point.

Fig.3-26

Programming

Type II:

The type II is different from the type I as follows:

1)Relative definition: more one parameter than the type I .

J:When J is not input or J is not 1, the system does not execute the run along the

roughing contour; J=1: the system executes the run along the roughing contour.

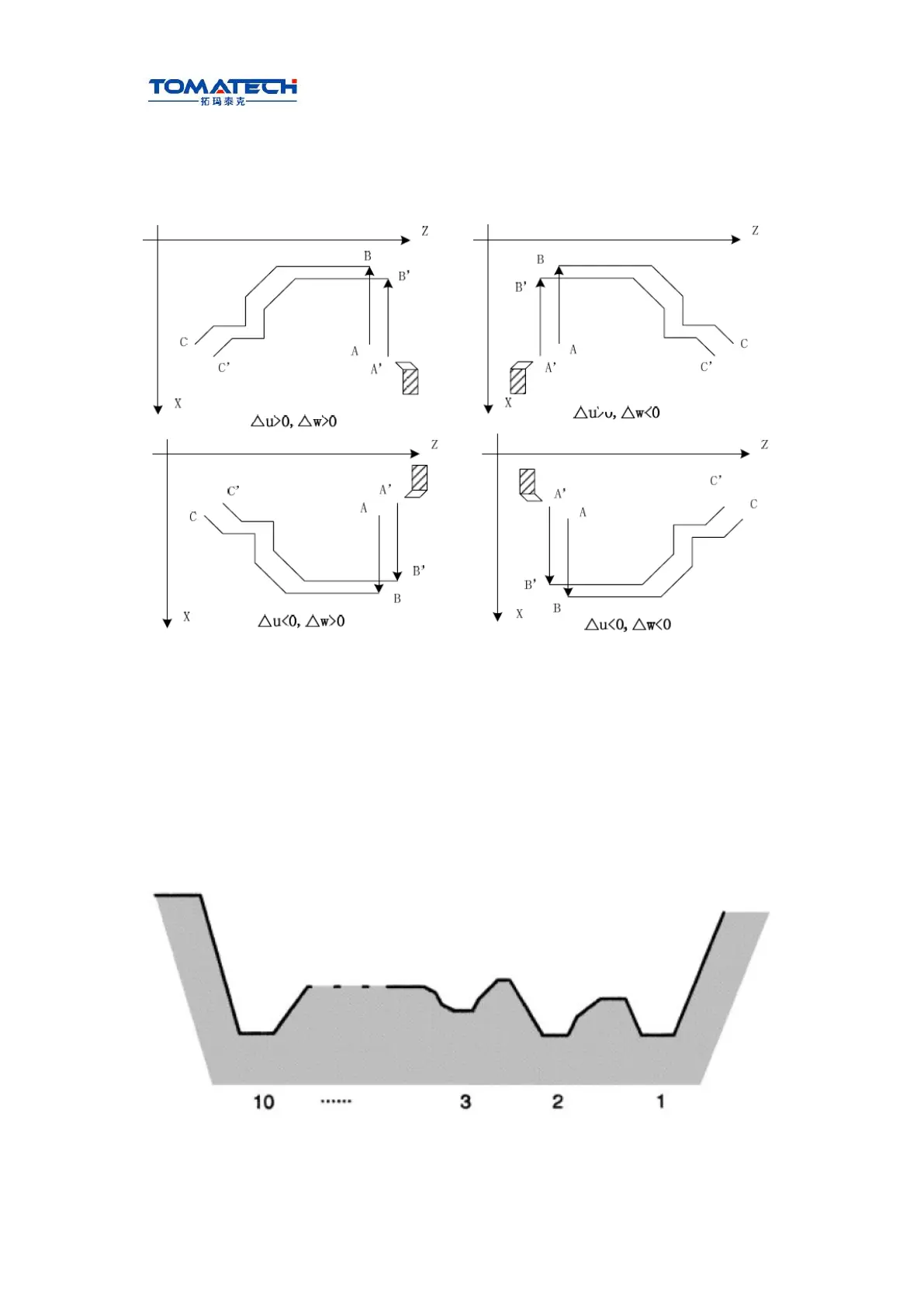

2)The system does not execute the monotonous increasing or the monotonous

decreasing along X external contour, and the workpiece can be up to 10 grooves as

follows:

Fig. 3-26-1(type Ⅱ)

But, the Z external contour must be the monotonous increasing or the monotonous

decreasing, and the following contour cannot be machined:

Loading...

Loading...