Multi Pro 5800Page 8 − 54GeoLink Spray System

Automatic Section Controller (ASC−10)

The controller opens and closes the various nozzle

valves, turning ON the flow of product to a nozzle as it

enters an area that has not been sprayed, and turning

OFF a nozzle as it exits an area that has already been

sprayed. The controller is also responsible for varying

the spray pump speed/system pressure and therefore

the application rate.

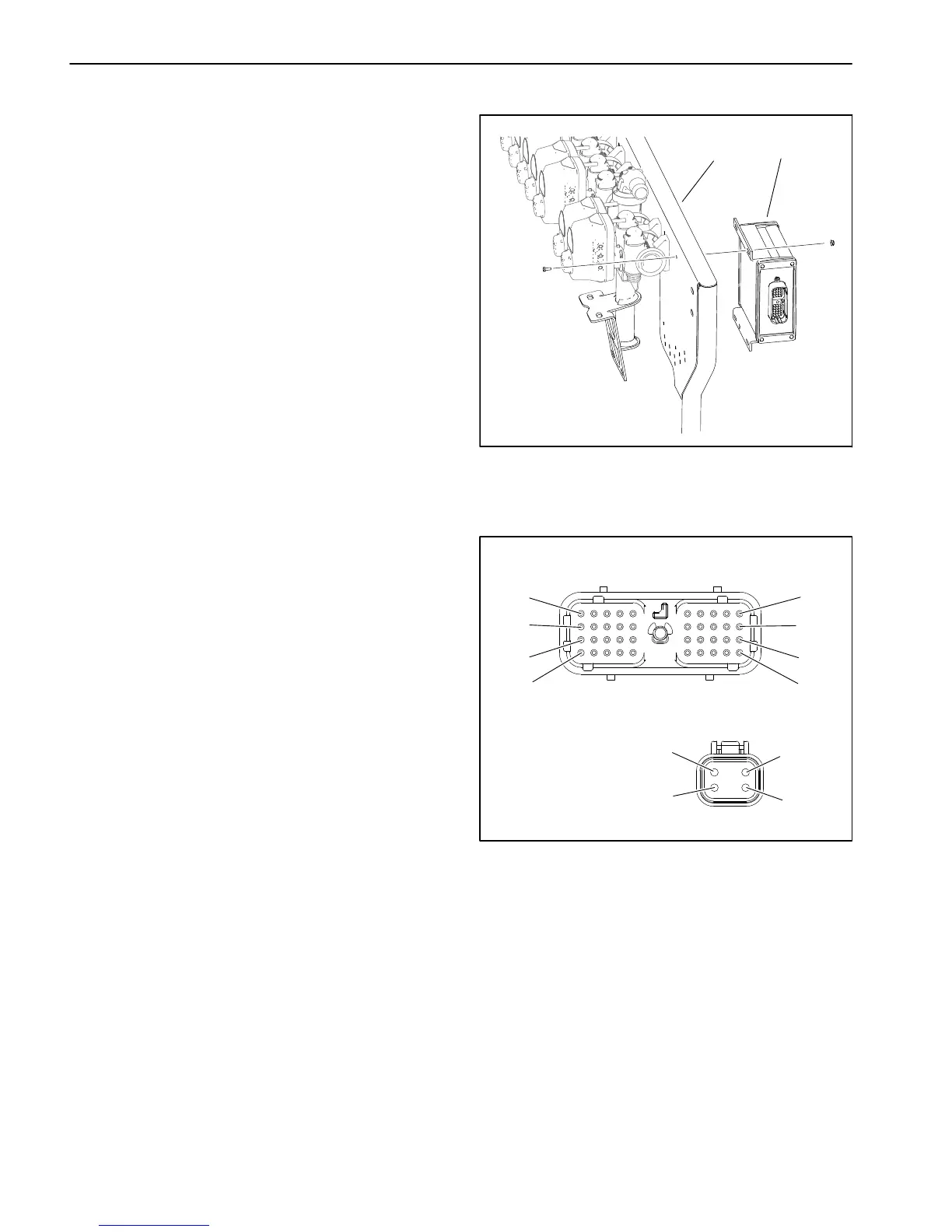

The controller is attached to the nozzle valve mount at

the rear of the machine (Fig. 62). Unswitched power is

provided to the controller as long as the battery cables

are connected to the battery. A 50 amp fuse provides cir-

cuit protection for the unswitched power to the con-

troller.

Three diagnostic LEDs are provided on the ASC−10 lo-

cated near the CAN−bus connecter:

STATUS: switched and unswitched power supply

status (flashing blue = OK)

RS232: not used

CAN: CAN−bus network status (flashing green =

OK)

The ASC−10 monitors the states of the following com-

ponents: boom section switches, flow meter and pres-

sure transducer.

The ASC−10 controls electrical output to the following

components: spray pump control solenoid and nozzle

valves.

The AGI−4 antenna, X25 or X30 control console and

ASC−10 auto section controller communicate with each

other on a CAN−bus network. The GeoLink Can−bus

network is separate from the sprayer traction unit CAN−

bus.

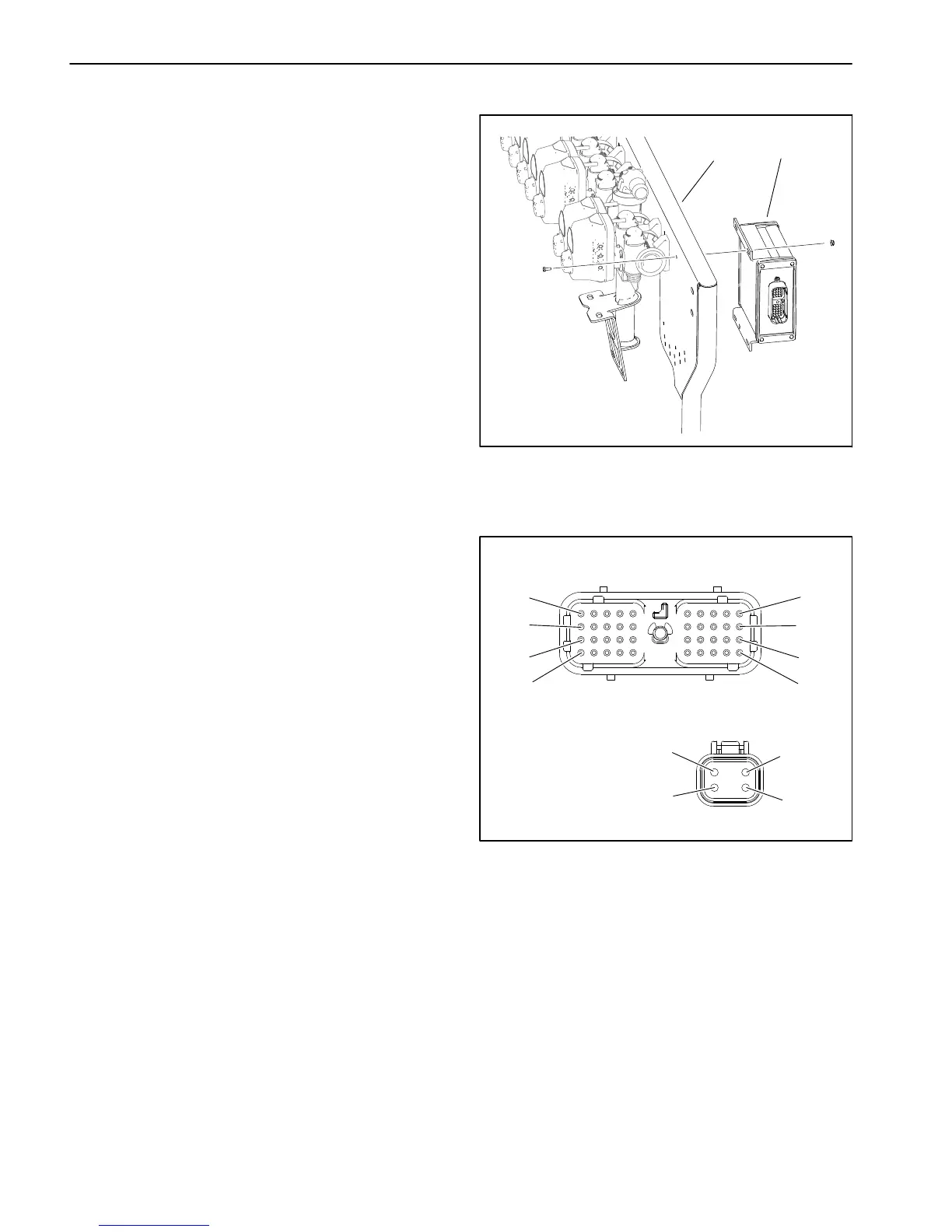

The connection terminal functions for the ASC−10 are

shown (Fig. 64). A forty (40) pin wire harness connector

and a four (4) pin wire harness connector attach to the

controller. The four (4) pin connector supports the

GeoLink CAN−bus network. The layout of the wire

harness connectors is shown (Fig. 63). See the

electrical schematics and wire harness drawings and

diagrams in Chapter 11 − Foldout Drawings in this

manual for additional information.

The GeoLink Spray System electrical schematic and

wire harness drawings in Chapter 11 − Foldout Draw-

ings can be used to identify possible circuit problems

between the controller and the input/output devices

(e.g. switches and valves).

1. Nozzle valve mount 2. Automatic section

controller (ASC−10)

Figure 62

1

2

Figure 63

WIRE HARNESS CONNECTORS FOR ASC−10

10

20

30

40

1

11

21

31

1

2

3

4

P40

P59

12 VDC UNSWITCHED − PINS 30, 39, 40

GROUND − PINS 9, 19, 29

Because of the solid state circuitry built into the ASC−10,

there is no method to test the controller directly. The con-

troller may be damaged if an attempt is made to test it

with an electrical test device (e.g. digital multimeter or

test light).

NOTE: The ASC−10, the X25 or X30 control console,

the GPS antenna assembly (including the modem and

the IMU for machines with RTK correction) are pro-

grammed specifically for each sprayer. If any of these

components require replacement for any reason, con-

tact the National Service Network (NSN) or your Toro

Distributor. The replacement components provided

should arrive pre−programmed for the specific sprayer.

Loading...

Loading...