3 Servomotor Specifications and Dimensional Drawings

3.8.1 Precautions on Servomotor Installation

3-38

3.8 Mechanical Specifications of SGMAH, SGMPH, SGMGH,

SGMSH, and SGMDH Servomotors

3.8.1 Precautions on Servomotor Installation

Servomotors can be installed either horizontally or vertically.

The service life of the servomotor will be shortened or unexpected problems will occur if the servomotor is

installed incorrectly or in an inappropriate location. Always observe the following installation instructions.

• Do not connect the servomotor directly to a commercial power line. This

will damage the servomotor.

The servomotor cannot operate without the proper SERVOPACK.

Storage

Temperature

and Humidity

Store the servomotor within the following temperature range if it is stored with the power cable discon-

nected.

Surrounding air temperature during storage: -20 to 60°C

Ambient humidity during storage: 80%RH or less (with no condensation)

Installation Site

Servomotors are designed for indoor use. Install the servomotor in environments that satisfy the follow-

ing conditions.

• Free of corrosive or explosive gases.

• Well-ventilated and free of dust and moisture.

• Surrounding air temperature of 0 to 40°C

• Relative humidity of 20% to 80% with no condensation.

• Facilitates inspection and cleaning

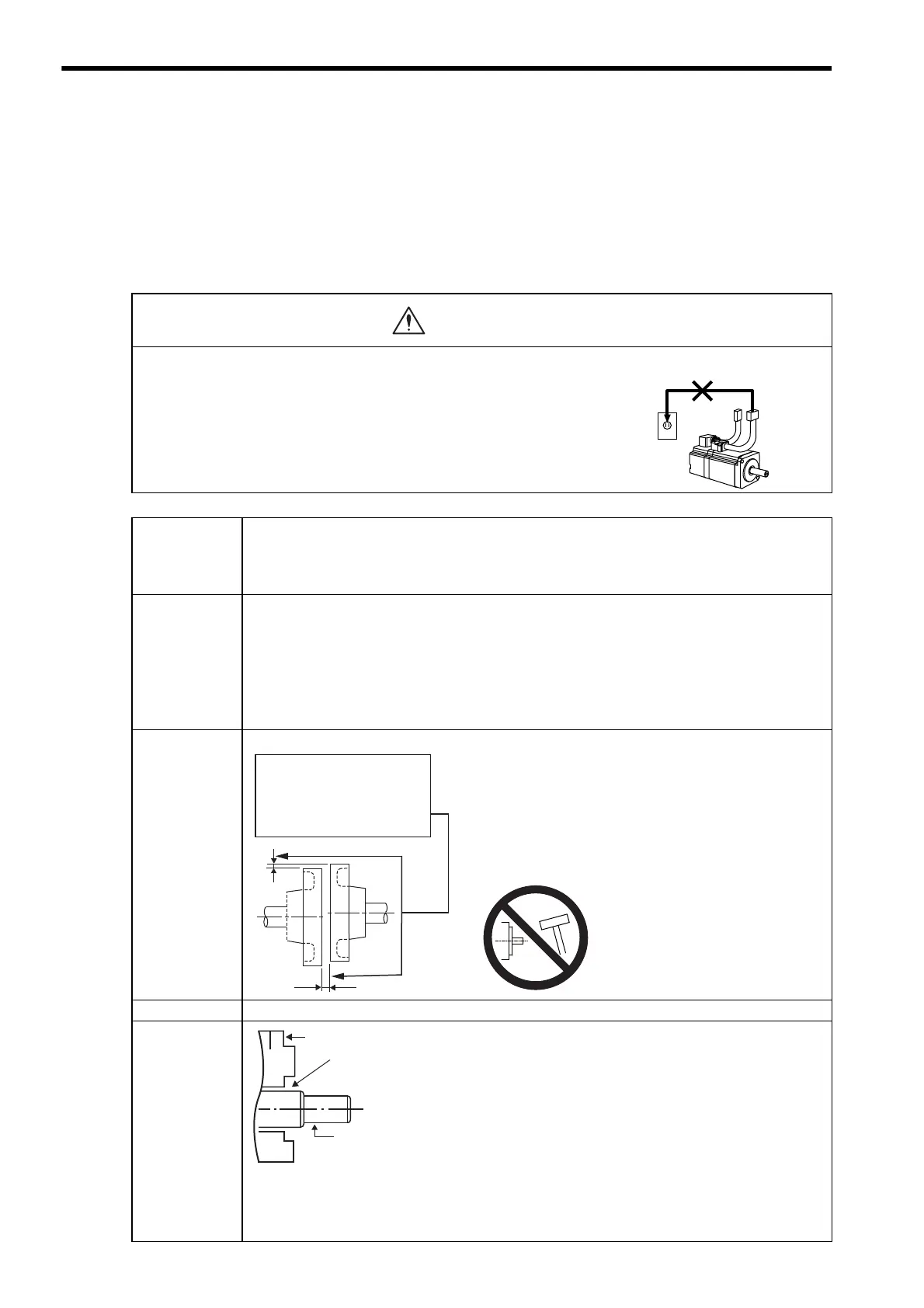

Alignment

Align the shaft of the servomotor with the shaft of the equip-

ment, and then couple the shafts. Install the servomotor so that

alignment accuracy falls within the range described on the left.

Vibration may occur and damage the bearings and encoders if

the shafts are not correctly aligned.

Connect the servomotor to a machine in the way that prevents

from generating concentric loads, or rotary unbalanced loads

on the motor shaft.

When installing, do not hit the

shafts with a hammer etc., as

impacts may result in malfunction.

Orientation Servomotors can be installed either horizontally or vertically.

Handling Oil

and Water

If the servomotor is used in a location that is subject to water

drops, make sure of the servomotor protective specifications

(except for through shaft section).

If the servomotor is used in a location that is subject to water or

oil mist, use a servomotor with an oil seal to seal the through

shaft section.

Precautions on Using Servomotor With Oil Seal

• The oil surface must be under the oil seal lip.

• Use an oil seal in favorably lubricated condition.

• When using a servomotor with its shaft pointed upward, be

sure that oil will not stay in the oil seal lips.

Measure this distance at four

different positions on the

circumference. The difference

between the maximum and

minimum measurements must be

0.03 mm or less.

(Turn together with coupling.)

Alignment Accuracy

Through shaft section:

Shaft

Flange

This refers to the gap where

the shaft protrudes from

the end of the motor.

Loading...

Loading...