3 Servomotor Specifications and Dimensional Drawings

3.2.3 SGMPH Servomotors With Low-backlash Gears

3-14

3.2.3 SGMPH Servomotors With Low-backlash Gears

* 1. Maximum motor speed is up to 4000 min

-1

at the shaft.

* 2. Gear output torque is expressed using the following equation.

(Gear output torque) = (servomotor output torque) × × (efficiency)

* 3. The instantaneous peak torque values indicated with ∗3 are limited by the gear, so use the following

servomotor instantaneous peak torque. In this case, set torque limit parameters Pn402 and 403 for the

SERVOPACK at 250%.

The no-load torque for a servomotor with gears is high immediately after the servomotor starts, and it then

decreases and becomes stable a few minutes later. This is a common phenomenon caused by grease being

circulated in the gear and not by a faulty gear.

The speed control range of SERVOPACKs in the Σ-II series is 1:5000. When using servomotors at

extremely low speeds (for example, 0.02 min

-1

max. at the gear output shaft) or when using servomotors

with one pulse feed reference for extended periods and in other situations that are less than optimum, the

lubrication of the gear bearing may be insufficient. This may cause deterioration of the bearing or increase

the load ratio.

Contact your Yaskawa representative if you are using your servomotor under such conditions.

• Time Rating: Continuous

• Vibration Class: 15 μm or below

• Insulation Resistance: 500 VDC, 10 MΩ min.

• Surrounding Air Temperature: 0 to 40°C

• Excitation: Permanent magnet

• Mounting: Flange-mounted

• Gear Mechanism: Planetary gear mechanism

• Thermal Class: B

• Withstand Voltage:

100V, 200V Servomotors: 1500 VAC for one minute

• Enclosure: Totally enclosed, self-cooled, IP55 (except

for shaft opening)

• Ambient Humidity: 20% to 80% (no condensation)

• Drive Method: Direct drive

• Backlash: 3 min max.

• Gear Rotation Direction: Same direction as servomotor

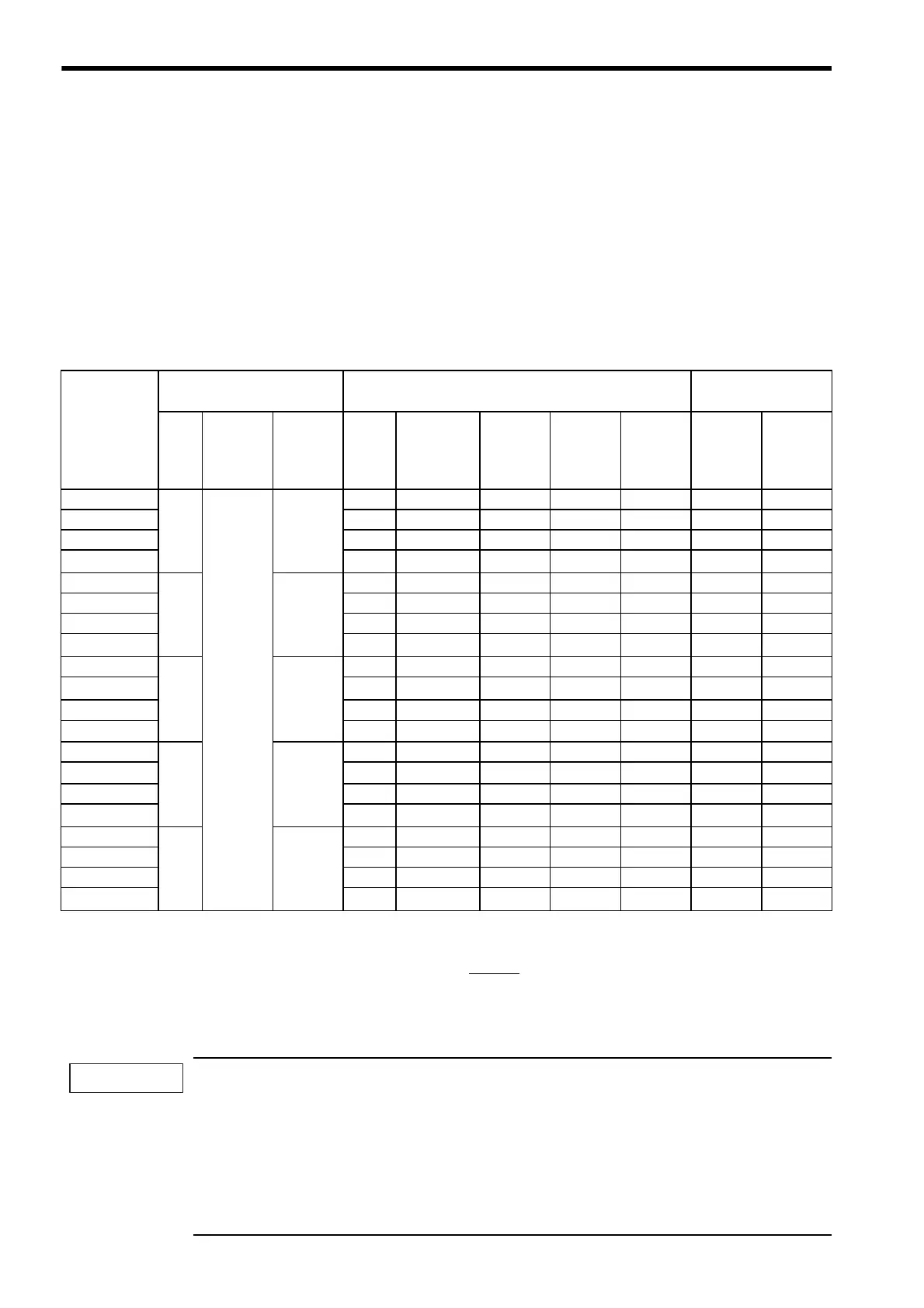

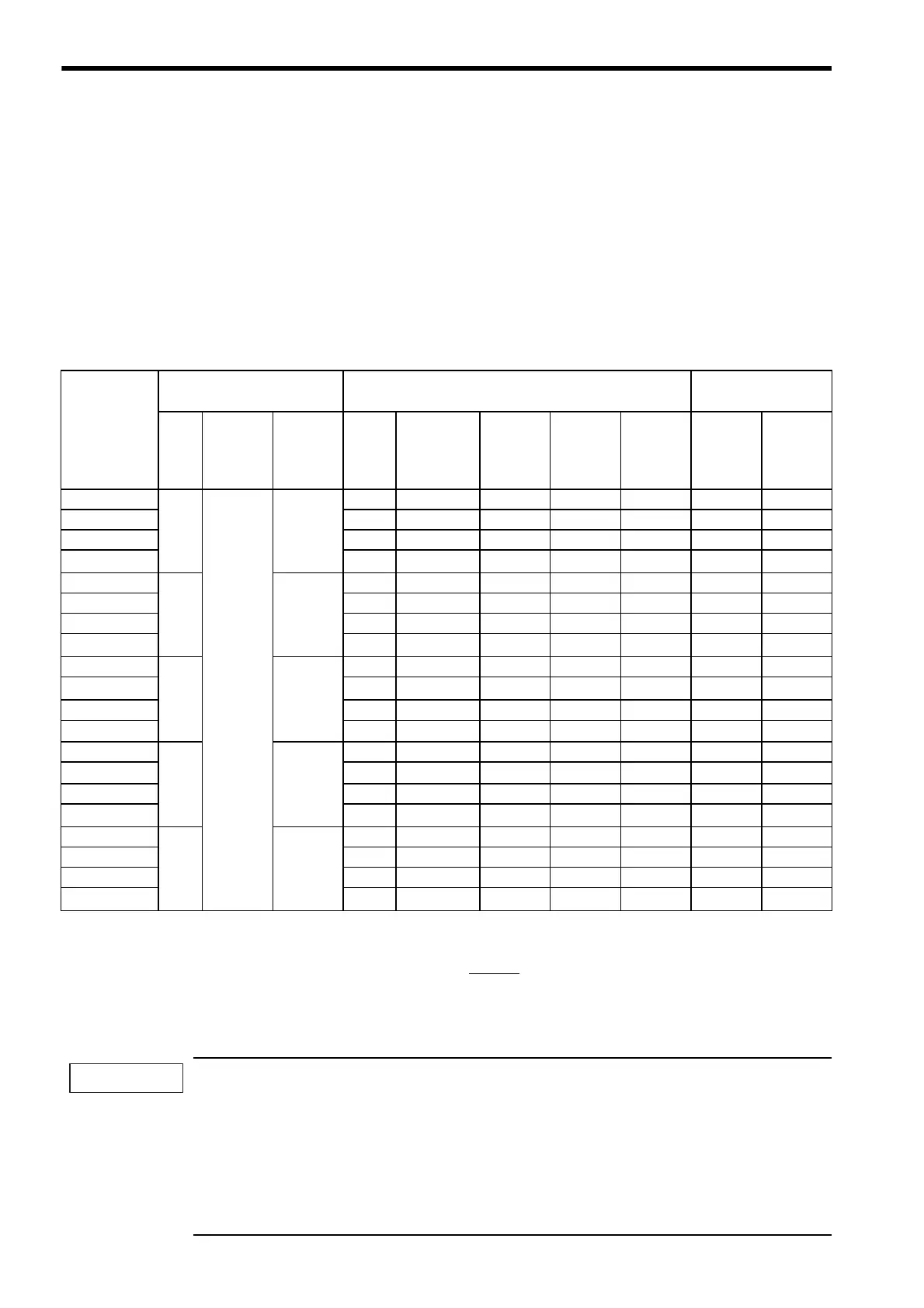

Servomotor

Model

SGMPH-

Servomotor Gear Output

Moment of Inertia J

×10

-4

kg·m

2

Out-

put

W

Rated

Speed

min

-1

Rated

Torq ue

Nxm

Gear

Ratio

Rated

Torque/Effi-

ciency

∗

2

N·m/%

Instanta-

neous

Peak

Tor que

N·m

Rated

Speed

min

-1

Max.

Speed

∗1

min

-1

Motor +

Gears

Gears

01H1

100

3000

0.318

1/5 1.27/80 4.34 600 800 0.142 0.093

01HB

1/11 2.80/80 9.55 273 363 0.097 0.048

01HC

1/21 5.34/80 18.2 143 190 0.092 0.043

01H7

1/33 8.40/80

28.7

∗3

91 121 0.082 0.033

02H1

200 0.637

1/5 2.55/80 8.4 600 800 0.553 0.360

02HB

1/11 5.96/85 19.3 273 363 0.281 0.088

02HC

1/21 11.4/85 37.3 143 190 0.303 0.110

02H7

1/33 17.9/85

58.6

∗3

91 121 0.258 0.065

04H1

400 1.27

1/5 5.4/85 17.6 600 800 0.691 0.360

04HB

1/11 11.9/85

39.1

∗3

273 363 0.526 0.195

04HC

1/21 22.7/85 72.2 143 190 0.526 0.195

04H7

1/33 33.5/80

115

∗3

91 121 0.504 0.172

08H1

750 2.39

1/5 10.2/85 33.3 600 800 2.87 0.765

08HB

1/11 22.3/85

71

∗3

273 363 2.62 0.523

08HC

1/21 42.7/85 140 143 190 2.76 0.663

08H7

1/33 67/85

206

∗3

91 121 2.56 0.455

15H1

1500 4.77

1/5 20.3/85 65.9 600 800 5.56 1.54

15HB

1/11 44.6/85 148 273 363 6.11 2.09

15GC

1/21 80.1/80 270 143 190 6.00 1.98

15G7

1/33 126/80

353

∗3

91 121 5.14 1.12

Loading...

Loading...