3 Servomotor Specifications and Dimensional Drawings

3.4.2 SGMGH servomotors (1000 min

-1

) With Standard Backlash Gears

3-24

3.4.2 SGMGH servomotors (1000 min

-1

) With Standard Backlash Gears

* For oil lubrication, the motor should be mounted horizontal to the shaft. Contact your Yaskawa

representative about lubrication for angle mounting.

Note: Contact your Yaskawa representative regarding the use of servomotors in cases such as

when the servomotor is frequently started and stopped, or when impact is generated on the

gear output shaft by acceleration and deceleration.

• Time Rating: Continuous • Excitaton: Permanent magnet

• Thermal Class: F

• Withstand Voltage: 1500 VAC for one minute

• Enclosure: Totally enclosed, IP44 self-cooled

(or the equivalent)

• Ambient Humidity: 20% to 80%

(no condensation)

• Drive Method: Direct drive

• Backlash: Roughly 0.6 to 2° at gear output shaft

• Gear Rotation Direction: Reverse direction of servomotor

• Gear Mechanism: Cyclo gear mechanism

• Vibration Class: 15 μm or below

• Insulation Resistance: 500 VDC,

10 MΩ min.

• Surrounding Air Temperature: 0 to 40°C

• Mounting: Foot and flange-mounted

Type 6090 to 6125: Omni-directional mounting

Type 6130 to 6190: Horizontal mounting to shaft

• Gear Lubricating Method:

Type 6090 to 6125: Grease

Type 6130 to 6190: Oil

∗

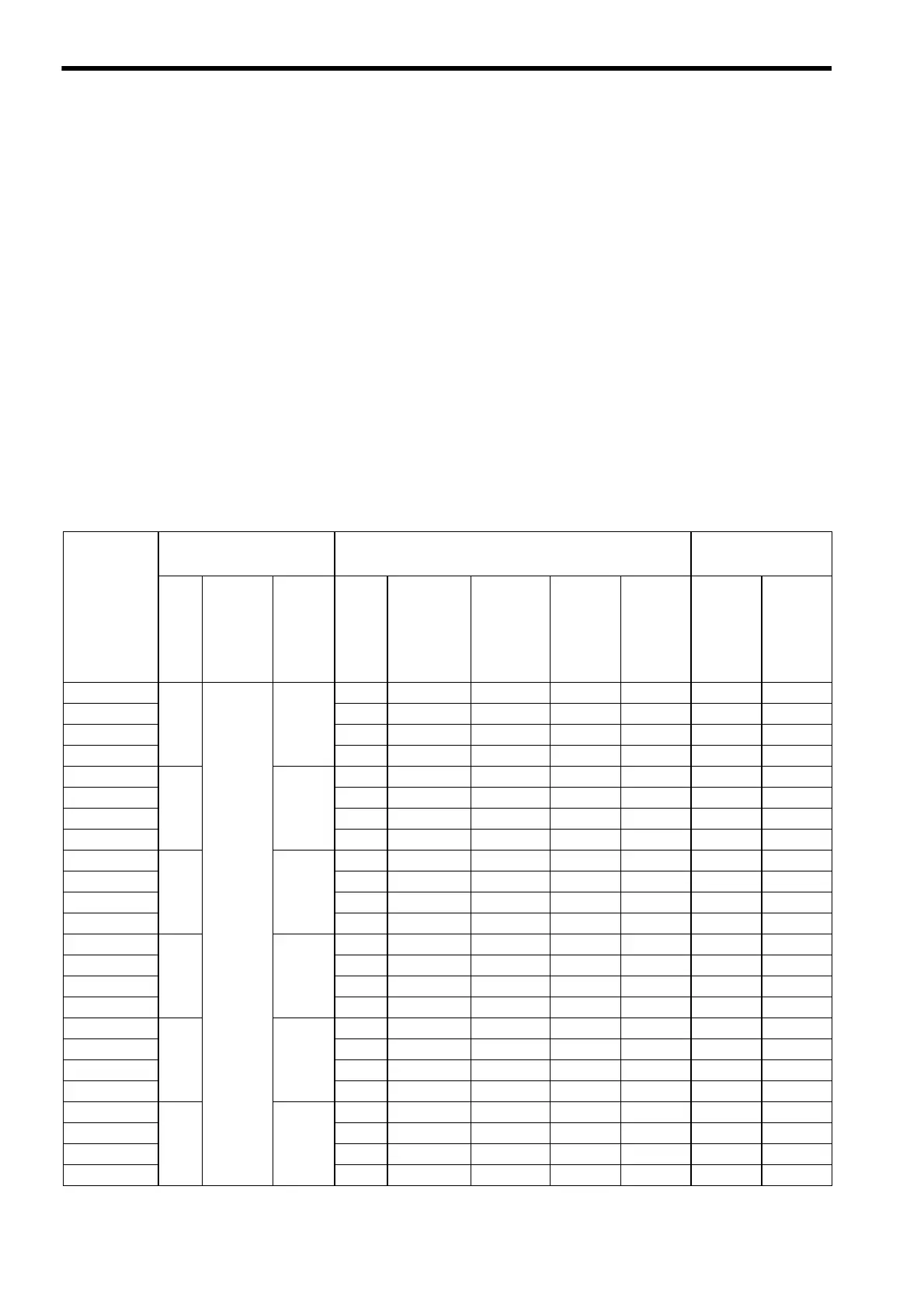

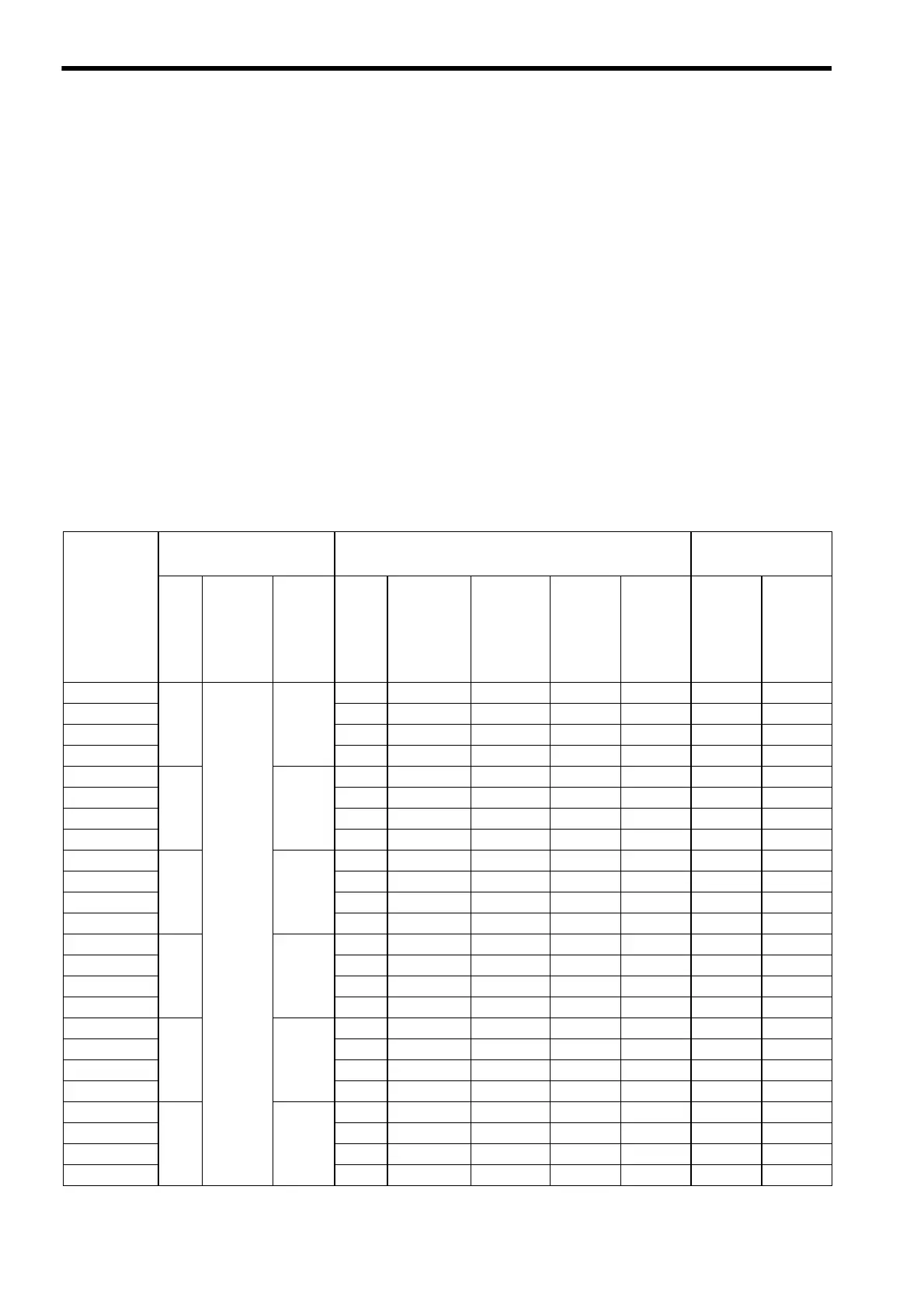

Servomotor

Model

SGMGH-

Servomotor Gear Output

Moment of Inertia J

×10

-4

kg·m

2

Out-

put

kW

Rated

Speed

min

-1

Rated

Tor que

Nxm

Gear

Ratio

Rated

Torque/

Efficiency

N·m/%

Instanta-

neous

Peak

Torque/

Effective

N·m/%

Rated

Speed

min

-1

Max.

Speed

min

-1

Motor +

Gears

Gears

03PBA6

0.3

1000

2.84

1/6 12.8/75 32.3/75 166 333 9.20 1.96

03PBB6

1/11 25.0/80 63.1/80 90 181 8.84 1.6

03PBC6

1/21 47.7/80 120/80 47 95 8.39 1.15

03PB76

1/29 65.9/80 166/80 34 68 8.41 1.17

06PBA6

0.6 5.68

1/6 27.3/80 67.7/80 166 333 15.7 1.78

06PBB6

1/11 50.0/80 124/80 90 181 15.3 1.35

06PBC6

1/21 95.4/80 237/80 47 95 15.9 1.97

06PB76

1/29 132/80 327/80 34 68 16.1 2.19

09PBA6

0.9 8.62

1/6 41.4/80 92.6/80 166 333 22.3 1.84

09PBB6

1/11 75.9/80 170/80 90 181 21.9 1.41

09PBC6

1/21 145/80 324/80 47 95 22.5 2.03

09PB76

1/29 200/80 448/80 34 68 22.7 2.24

12PBA6

1.2 11.5

1/6 58.7/85 143/85 166 333 38.0 6.3

12PBB6

1/11 108/85 262/85 90 181 36.5 4.76

12PBC6

1/21 205/85 500/85 47 95 37.6 5.93

12PB76

1/29

283/85 690/85 34 68 37.3 5.58

20PBA6

2.0 19.1

1/6 97.4/85 224/85 166 333 52.3 6.3

20PBB6

1/11 179/85 411/85 90 181 50.8 4.76

20PBC6

1/21 341/85 785/85 47 95 51.9 5.93

20PB76

1/29 471/85 1080/85 34 68 78.5 32.5

30PBA6

3.0 28.4

1/6 145/85 325/85 166 333 79.5 12.0

30PBB6

1/11 266/85 596/85 90 181 75.2 7.73

30PBC6

1/21 507/85 1140/85 47 95 101 33.6

30PB76

1/29 700/85 1570/85 34 68 121 53.3

Loading...

Loading...