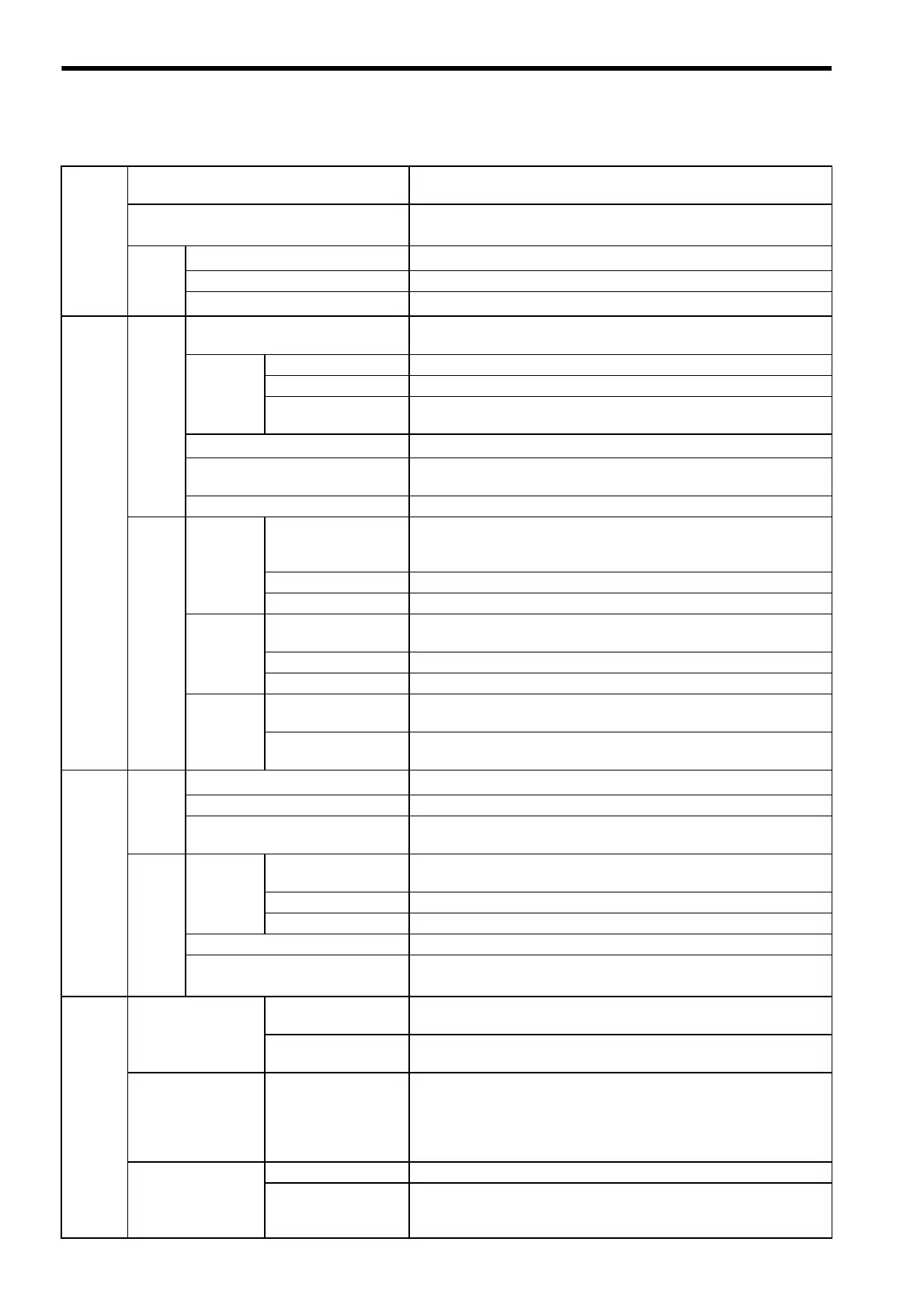

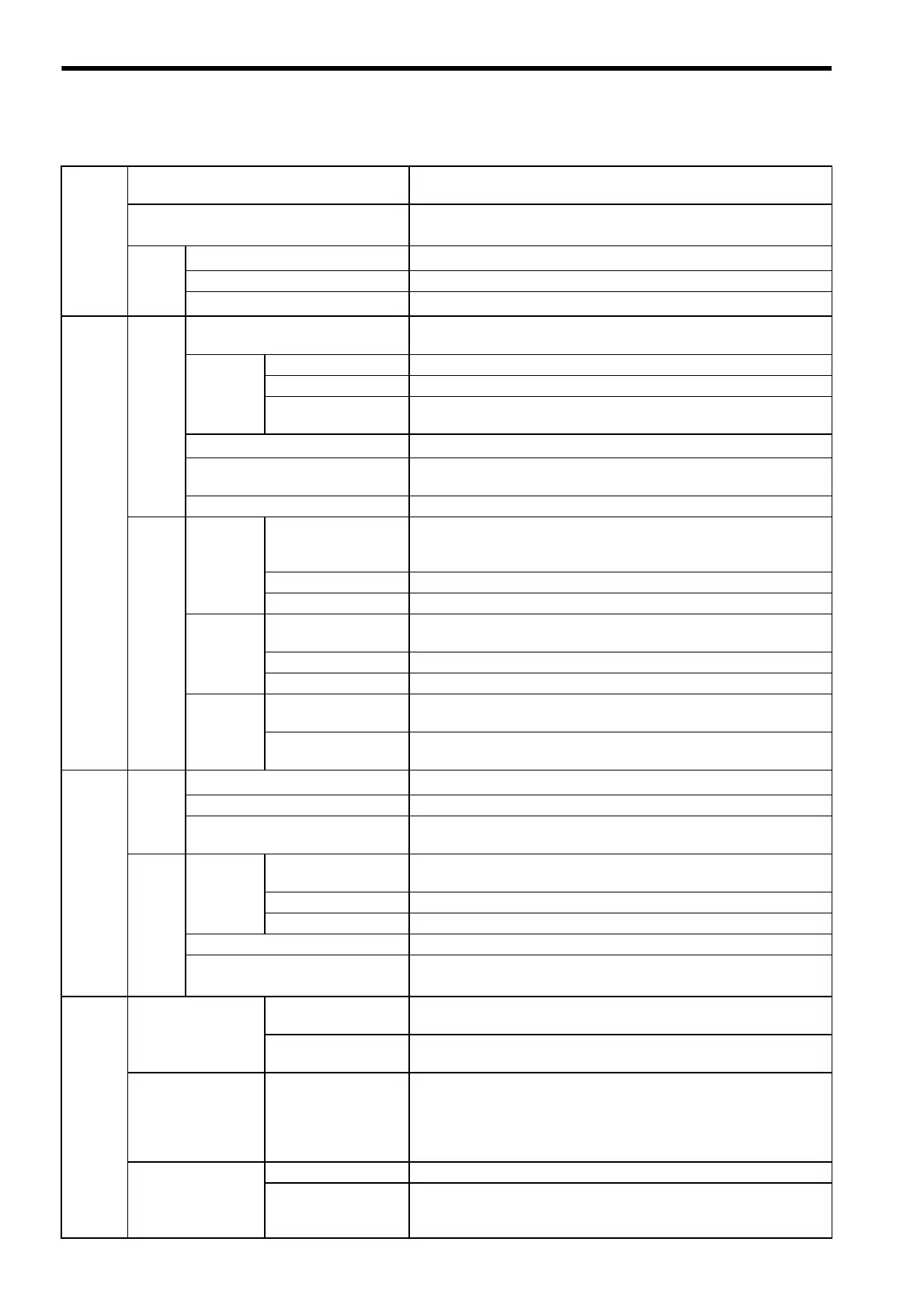

4 SERVOPACK Specifications and Dimensional Drawings

4.1.3 SERVOPACK Ratings and Specifications

4-4

4.1.3 SERVOPACK Ratings and Specifications

Basic

Specifi-

cations

Control Method

Single or three-phase full-wave rectification IGBT-PWM (sine-wave

driven)

Feedback

Serial encoder: 13, 16 or 17-bit (incremental/absolute)

∗

The 13-bit encoder is incremental only.

Condi-

tions

Ambient/Storage Temperature

∗1

0 to +55 °C/-20 to +85 °C

Ambient/Storage Humidity 90% RH or less (with no condensation)

Vibration/Shock Resistance

4.9 m/s

2

/19.6 m/s

2

Speed

and

Tor que

Control

Modes

Perfor-

mance

Speed Control Range

1:5000 (The lowest speed of the speed control range is the speed at which

the servomotor will not stop with a rated torque load.)

Speed

Regula-

tion

∗2

Load Regulation 0 to 100% load: ±0.01% or less (at rated speed)

Voltage Regulation Rated voltage ±10%: 0% (at rated speed)

Temperature Regula-

tion

25 ± 25 °C: ±0.1% or less (at rated speed)

Frequency Characteristics

400 Hz (at J

L

= J

M

)

Torque Control Tolerance

(Repeatability)

±2%

Soft Start Time Setting 0 to 10 s (Can be set individually for acceleration and deceleration.)

Input

Signals

Speed

Reference

Input

Reference Voltage

∗3

±6 VDC (Variable setting range: ±2 to ±10 VDC) at rated torque (servo-

motor forward rotation with positive reference), input voltage: maximum

±12 V

Input Impedance About 14 kΩ

Circuit Time Constant About 47 μs

Torque

Reference

Input

Reference Voltage

∗3

±3 VDC (Variable setting range: ±1 to ±10 VDC) at rated torque (positive

torque reference with positive reference), input voltage: maximum ±12 V

Input Impedance About 14 kΩ

Circuit Time Constant About 47 μs

Contact

Speed

Reference

Rotation Direction

Selection

With P control signal

Speed Selection

With forward/reverse current limit signal (speed 1 to 3 selection), servo-

motor stops or another control method is used when both are OFF.

Position

Control

Modes

Perfor-

mance

Bias Setting

0 to 450 min

-1

(setting resolution: 1 min

-1

)

Feed Forward Compensation 0 to 100% (setting resolution: 1%)

Positioning Completed Width

Setting

0 to 250 reference units (setting resolution: 1 reference unit)

Input

Signals

Reference

Pulse

Type

Sign + pulse train, 90° phase difference 2-phase pulse (phase A + phase

B), or CCW + CW pulse train

Form Line driver (+5 V level), open collector (+5 V or +12 V level)

Frequency Maximum 500/200 kpps (line driver/open collector)

Control Signal Clear signal (input pulse form identical to reference pulse)

Built-in Open Collector Power

Supply

∗4

+12 V (1kΩ resistor built in)

I/O

Signals

Position Output

Form

Phase-A, -B, -C line driver

Phase-S line driver (only with an absolute encoder)

Frequency Dividing

Ratio

Any

Sequence Input

Signal allocation can

be modified.

Servo ON, P control (or Control mode switching, forward/reverse motor

rotation by internal speed setting, zero clamping, reference pulse prohib-

ited), forward run prohibited (P-OT), reverse run prohibited (N-OT),

alarm reset, forward current limit, and reverse current limit (or internal

speed selection)

Sequence Output

Fixed Output Servo alarm, 3-bit alarm codes

Signal allocation can

be modified.

Positioning completed (speed coincidence), during servomotor rotation,

servo ready, during current limiting, during speed limiting, brake

released, warning, selecting three of the NEAR signals.

Loading...

Loading...