10 Upgraded Versions

10.5.6 Troubleshooting

10-22

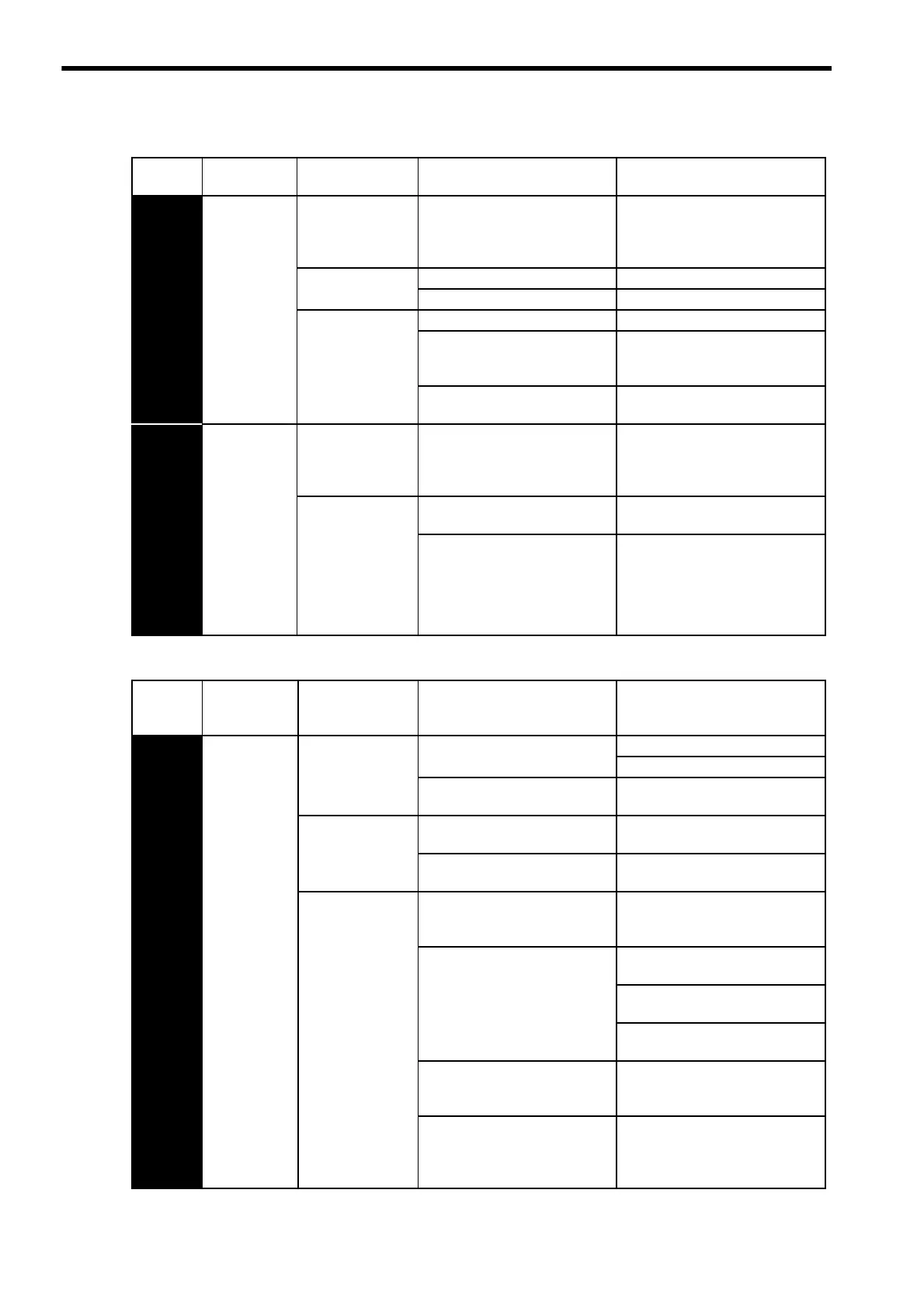

(b) Warning List

A.b3 Current

Detection

Error

Occurred when the

control power sup-

ply was turned

ON.

The current sensor is faulty. Replace the SERVOPACK.

Occurred when the

servo was ON.

The current sensor is faulty. Replace the SERVOPACK.

The servomotor is disconnected. Correct the servomotor wiring.

Occurred during

normal operation.

The current sensor is faulty. Replace the SERVOPACK.

The Servo ON command was

input while the servomotor was

operating.

Check to be sure the servomotor

has stopped, and then input the

Servo ON command.

The servomotor was discon-

nected.

Correct the servomotor wiring.

A.F5

A.F6

Servomotor

Disconnec-

tion Alarm

The power is

not supplied

to the servo-

motor though

the SERVO-

PACK

received the

Servo ON

command.

Occurred when the

control power sup-

ply was turned

ON.

A SERVOPACK board fault

occurred.

Replace the SERVOPACK.

Occurred when the

servo was ON.

A SERVOPACK board fault

occurred.

Replace the SERVOPACK.

The Servomotor was disconnect. Correct the servomotor wiring.

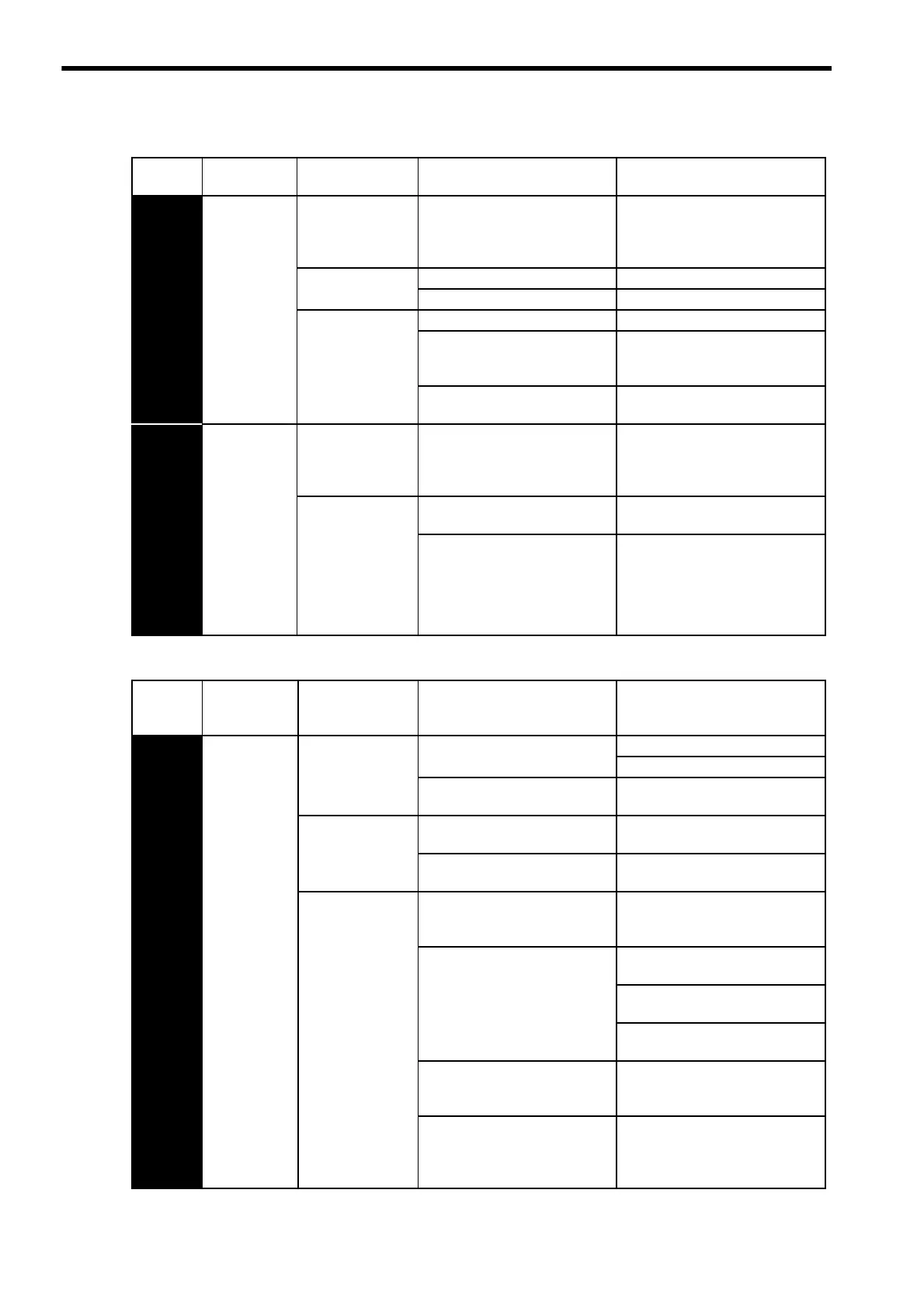

Warning

Display

Warning

Name

Situation at

Warning

Occurrence

Cause Corrective Actions

A.90 Excessive

Position Error

Warning:

Warning for

the alarm

A.d0

(In servo ON

status, the

position error

pulses exceed

the excessive

position error

warning level

set in the

parameter

Pn51E.)

Occurred at the

servomotor high-

speed rotation.

The contact in the servomotor U,

V, and W wirings is faulty.

Correct the servomotor wiring.

Correct the encoder wiring.

A SERVOPACK board fault

occurred.

Replace the SERVOPACK.

The servomotor

did not run with

position reference

input.

The contact in the servomotor U,

V, and W wirings is faulty.

Correct the servomotor wiring.

A SERVOPACK board fault

occurred.

Replace the SERVOPACK.

Normal move-

ment, but occurred

with a long dis-

tance reference

input.

The SERVOPACK gain adjust-

ment is improper.

Increase the speed loop gain

(Pn100) and position loop gain

(Pn102).

The position reference pulse fre-

quency is too high.

Adjust slowly the position refer-

ence pulse frequency.

Apply the smoothing function

(Pn204 or Pn205).

Correct the electronic gear ratio

(Pn202, Pn203).

Setting of the position error

pulse over flow warning level

(Pn51E) is incorrect.

Set the parameter Pn51E to proper

value.

The servomotor specifications

do not meet the load conditions

such as torque and moment of

inertia.

Reconsider and correct the load

and servomotor capacity.

(Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause Corrective Actions

Loading...

Loading...