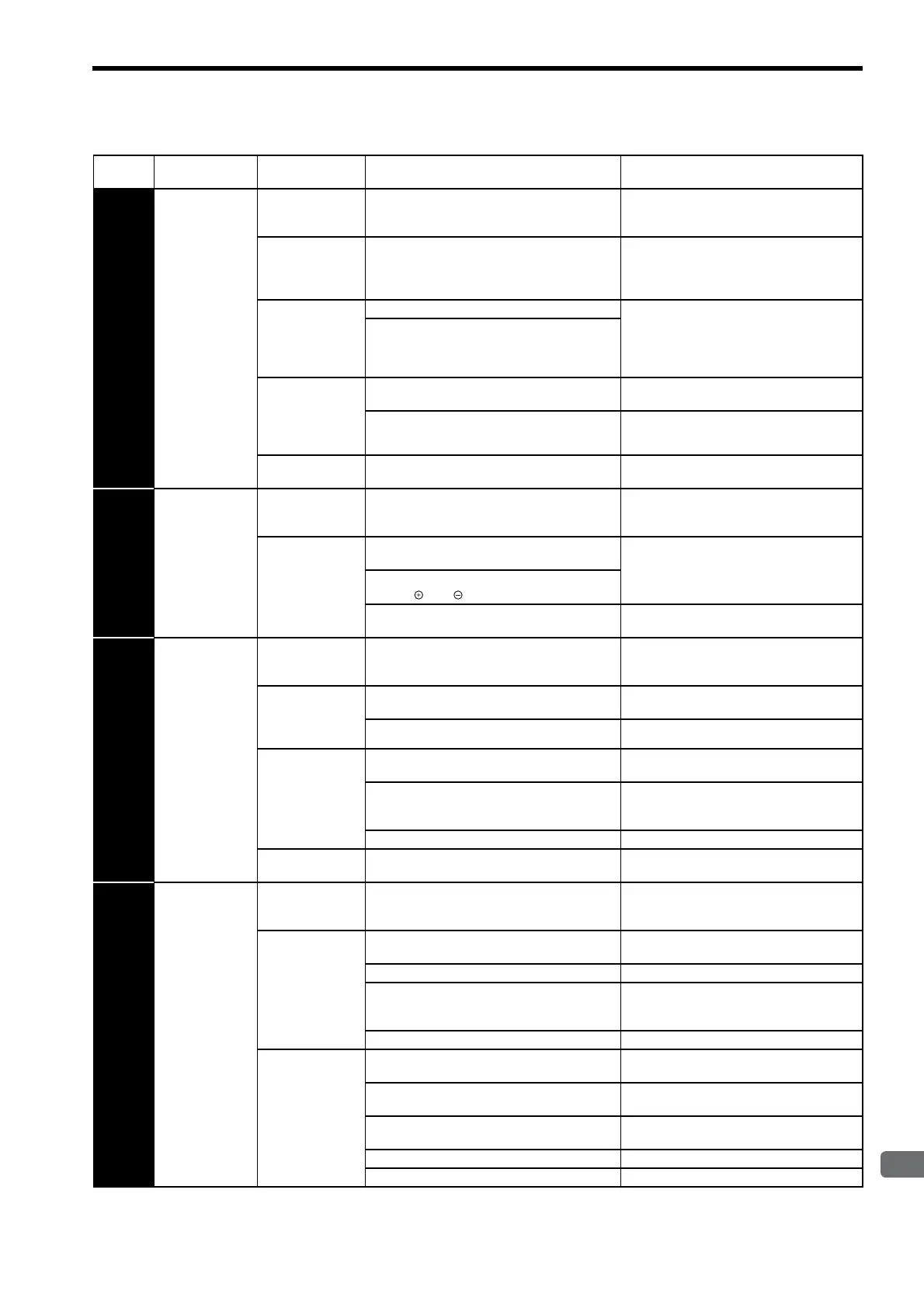

11.1 Troubleshooting

11-7

11

Inspection, Maintenance, and Troubleshooting

A.32

Regenerative

Overload

(Detected only

when the power

to the main circuit

is ON.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

The power supply voltage is 270 V or more. Correct the input voltage.

Occurred during

normal operation

(large increase of

regenerative resistor

temperature).

The regenerative energy is excessive.

Select a proper regenerative resistance capacity,

or reconsider the load and operation conditions.

The regenerating state continued.

Occurred during

normal operation

(small increase of

regenerative resistor

temperature).

The setting of parameter Pn600 is smaller than the

external regenerative resistor’s capacity.

Correct the set value of parameter Pn600.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred at servo-

motor deceleration.

The regenerative energy is excessive.

Select a proper regenerative resistance capacity,

or reconsider the load and operation conditions.

A.33

Main Circuit

Wiring Error

(Detected only

when the power

to the main circuit

is ON.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

In the DC power input mode, AC power is supplied

through L1 and L2 or L1, L2, and L3.

For AC power input, Pn001.2=0.

For DC power input, Pn001.2=1.

In the AC power input mode, DC power is supplied

through 1 and terminals.

Pn600 is set to 0 if the regenerative resistance is dis-

connected.

Set Pn600 to 0.

A.40

Overvoltage

(Detected when

the

SERVOPACK’s

main circuit DC

voltage is 240 V

(100 V class)/420

V (200 V class)

or more.)

(Detected only

when the power

to the main circuit

is ON.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

The AC power voltage is too high.

The AC power voltage must be within the speci-

fied range.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred during

normal operation.

Check the AC power voltage (check if there is no

excessive voltage change.)

The AC power voltage must be within the speci-

fied range.

The motor speed is high and load moment of inertia

is excessive, resulting in insufficient regenerative

capacity.

Reconsider the load and operation conditions.

Check the load moment of inertia and minus load

specifications.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred at servo-

motor deceleration.

The motor speed is high, and the load moment of

inertia is excessive.

Reconsider the load and operation conditions.

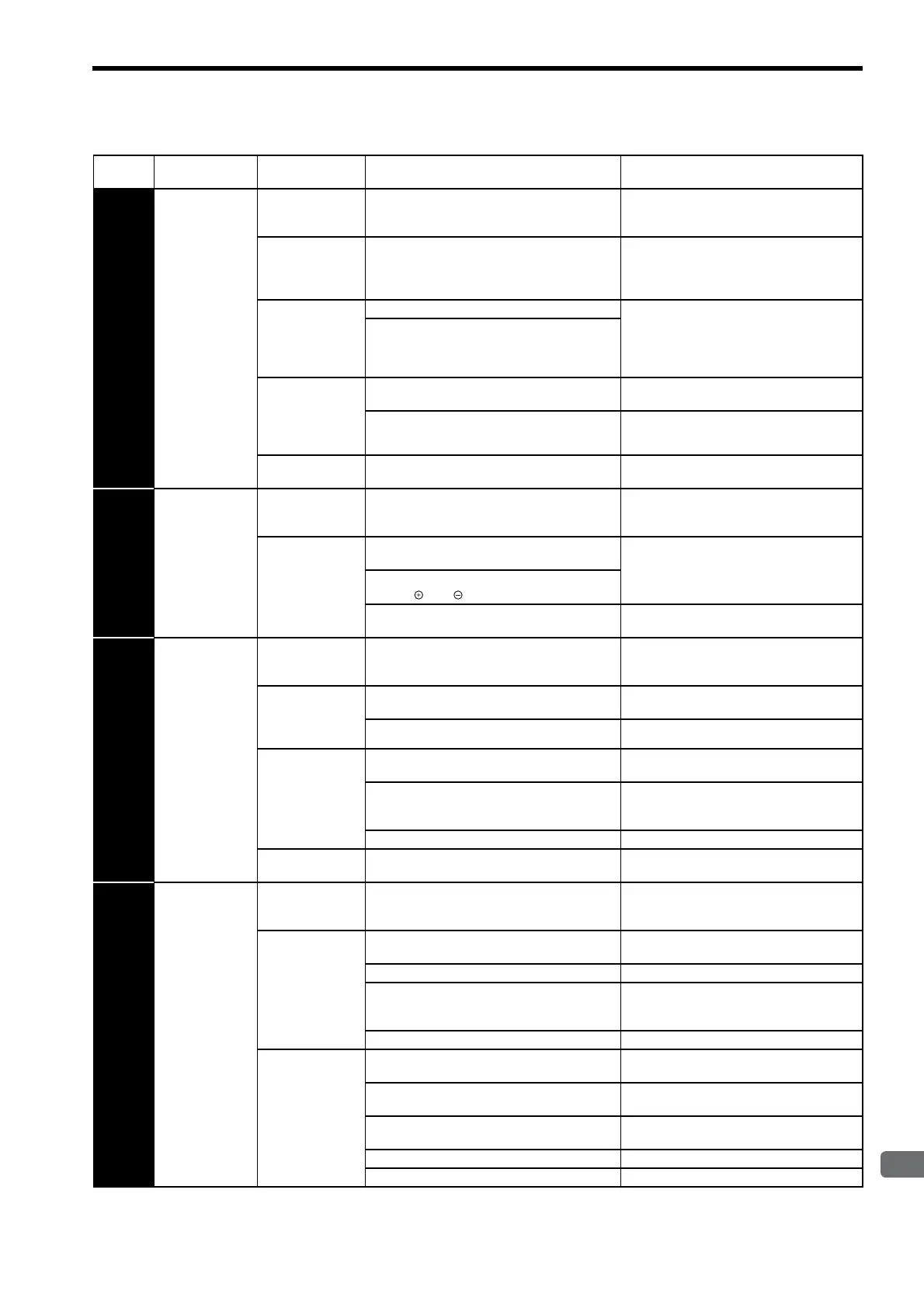

A.41

Undervoltage

(Detected when

the

SERVOPACK’s

main circuit DC

voltage is 85 V

(100 V class)/170

V (200 V class)

or less.)

(Detected only

when the power

to the main circuit

is ON.)

Occurred when the

control power sup-

ply was turned ON.

A SERVOPACK board fault occurred. Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

The AC power supply voltage is low.

The AC power supply voltage must be within the

specified range.

The fuse of the SERVOPACK is blown out. Replace the SERVOPACK.

The inrush current limit resistor is disconnected,

resulting in an abnormal power supply voltage or in

an overload of the inrush current limit resistor.

Replace the SERVOPACK. Check the power

supply voltage, and reduce the number of times

that the main circuit is turned ON or OFF.)

A SERVOPACK fault occurred. Replace the SERVOPACK.

Occurred during

normal operation.

The AC power supply voltage was lowered, and

large voltage drop occurred.

The AC power supply voltage must be within the

specified range.

A temporary power failure occurred.

Clear and reset the alarm, and restart the opera-

tion.

The servomotor main circuit cable is short-cir-

cuited.

Repair or replace the servomotor main circuit

cable.

The servomotor is short-circuited. Replace the servomotor.

A SERVOPACK fault occurred. Replace the SERVOPACK.

Table 11.3 Alarm Display and Troubleshooting (Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause Corrective Actions

Loading...

Loading...