12.1 Servomotor Capacity Selection Examples

12-5

(6) Load Acceleration Power

(7) Provisionally Servomotor Selection

(a) Selecting Conditions

• T

L

≤ Motor rated torque

• Pa + Po = (1 to 2) × Motor rated output

• N

M

≤ Motor rated speed

• J

L

≤ SERVOPACK allowable load moment of inertia

The followings satisfy the conditions.

• SGMPH-02A312 servomotor

• SGDM-02AP SERVOPACK (for position control)

(b) Specifications of Servomotor and SERVOPACK

• Rated output: 200 (W)

• Rated motor speed: 3000 (min

-1

)

• Rated torque: 0.637 (N⋅m)

• Instantaneous peak torque: 1.91 (N⋅m)

• Servomotor rotor moment of inertia: 0.209 × 10

-4

(kg⋅m

2

)

• SERVOPACK allowable load moment of inertia: 3.69 × 10

-4

(kg⋅m

2

)

• Number of encoder pulses: 2048 (P/R)

(8) Verification on Provisionally Selected Servomotor

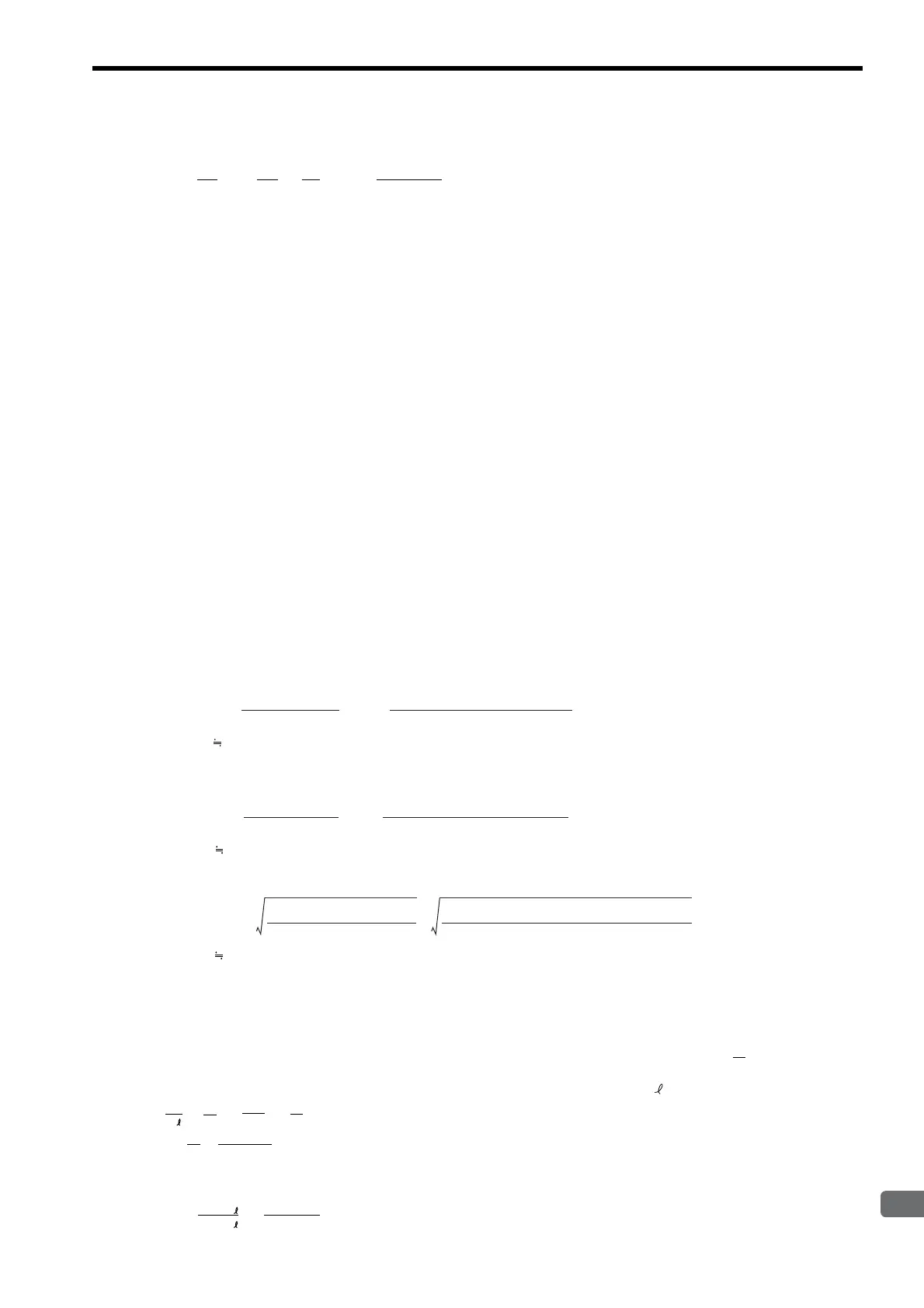

• Required starting torque

• Required braking torque

• Effective torque

The above confirms that the provisionally selected servomotor and SERVOPACK capacities are sufficient. In the

next step, their performance in position control are checked.

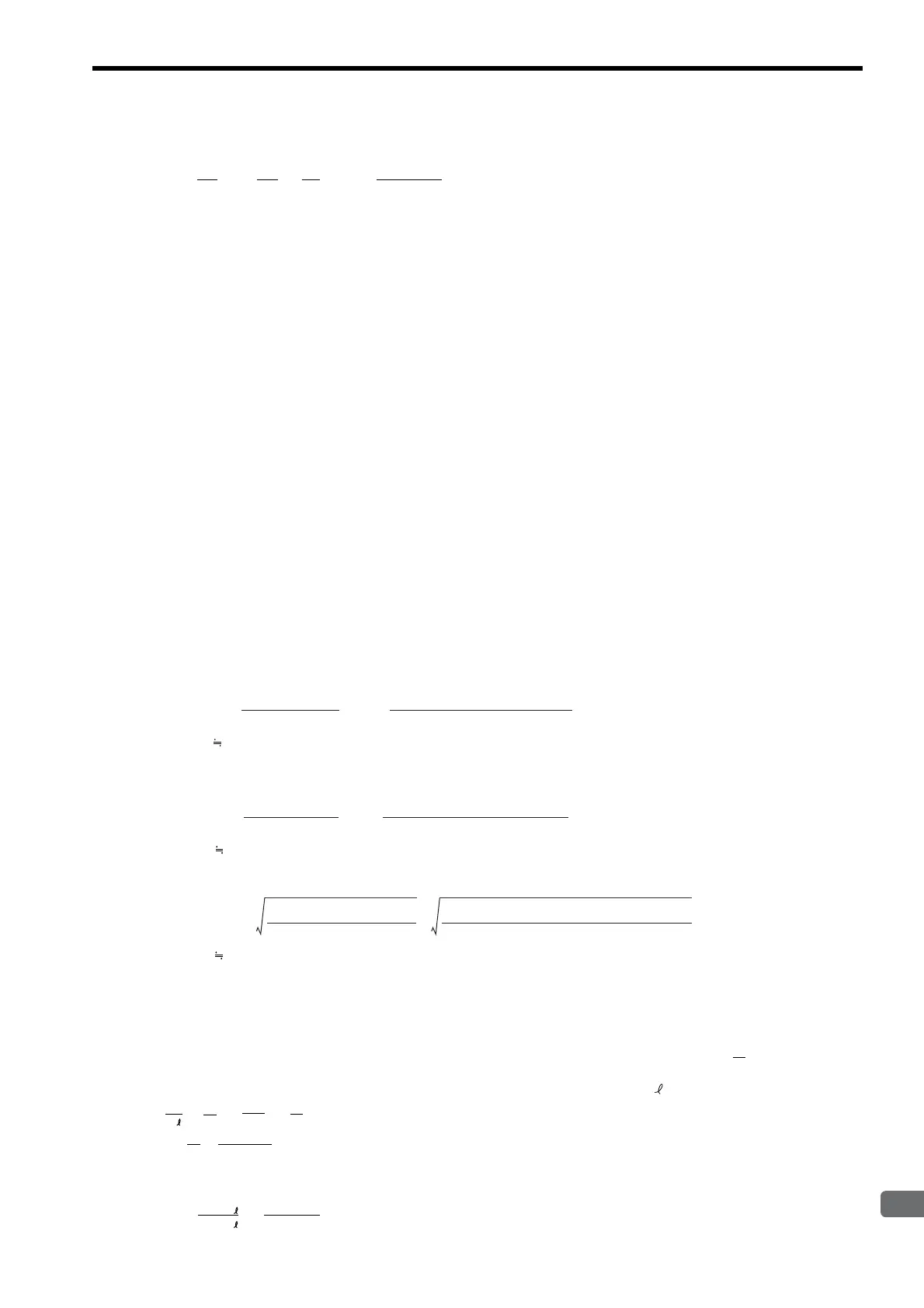

(9) PG Feedback Pulse Dividing Ratio: Setting of Electronic Gear Ratio

As the electrical stop accuracy δ = ±0.01mm, take the position detection unit Δ = 0.01mm/pulse.

(10) Reference Pulse Frequency

P

a

=

(

N

M

)

2

=

(

× 3000

)

2

-4

= 123.4 (W)

2π

60

2π

60

J

L

ta

1.25 × 10

0.1

T = + T = + 0.139

60ta 60 × 0.1

2

πN (J + J )

2

π × 3000 × (0.209 + 1.25) × 10

P

−4

MM L

L

0.597 (Nm) < Instantaneous peak torqueSatisfactory

T = − T = − 0.139

60ta 60 × 0.1

2

πN (J + J )

2

π × 3000 × (0.209 + 1.25) × 10

S

−4

MM L

L

0.319 (Nm) < Instantaneous peak torqueSatisfactory

T = =

t

Τ ta + T tc + T td

r m s

PLS

0.205 (Nm) < Rated torqueSatisfactory

222

1.5

(0.597) × 0.1 + (0.139) × 0.9 + (0.319) × 0.1

222

× = × = 2048 × 4

k = =

P

Δ

B

A

5

0.01

B

A

B

( )

B

A

2048 × 4

500

( )

vs = = = 25,000 (pps)

1000 × 15

60 × 0.01

1000V

60 × Δ

Loading...

Loading...