• If the motor vibrates, increase C4-02

• If the motor response is sluggish (and possibly stalls), decrease C4-02.

Note: Auto-Tuning significantly improves drive performance at low speeds.

n

C4-03: Torque Compensation at Forward Start (OLV only)

Sets the amount of torque at start (when rotating forward) as a percentage of the motor rated torque. This parameter may improve the motor performance

during start. This feature functions only when starting a motor in the forward direction. Torque reference and motor flux can be ramped up quickly to

improve speed response during start. A setting of 0.0 disables this feature.

No. Parameter Name Setting Range Default

C4-03 Torque Compensation at Forward Start 0.0 to 200.0 0.0%

n

C4-04: Torque Compensation at Reverse Start (V/f Control)

This parameter may improve the motor performance during start. This feature functions only when starting a motor in the reverse direction. Torque

reference and motor flux can be ramped up quickly to improve speed response during start. A setting of 0.0 disables this feature.

No. Parameter Name Setting Range Default

C4-04 Torque Compensation at Reverse Start -200.0 to 0.0 0.0%

n

C4-05: Torque Compensation Time Constant (OLV only)

This parameter is the time delay that will be applied to the torque compensation parameters C4-03 and C4-04.

No. Parameter Name Setting Range Default

C4-05 Torque Compensation Time Constant 0 to 200 10 ms

n

C4-06: Torque Compensation Primary Delay Time 2 (V/f Control)

Increase settings when acceleration is complete, or if an overvoltage fault or error occurs with sudden changes in the load. Adjustment is not normally

required.

No. Parameter Name Setting Range Default

C4-06 Torque Compensation Primary Delay Time 2 0 to 10000 150 ms

Note: If C4-06 is set to a relatively large value, be sure to also increase the setting in n2-03 (AFR Time Constant 2) proportionally.

u

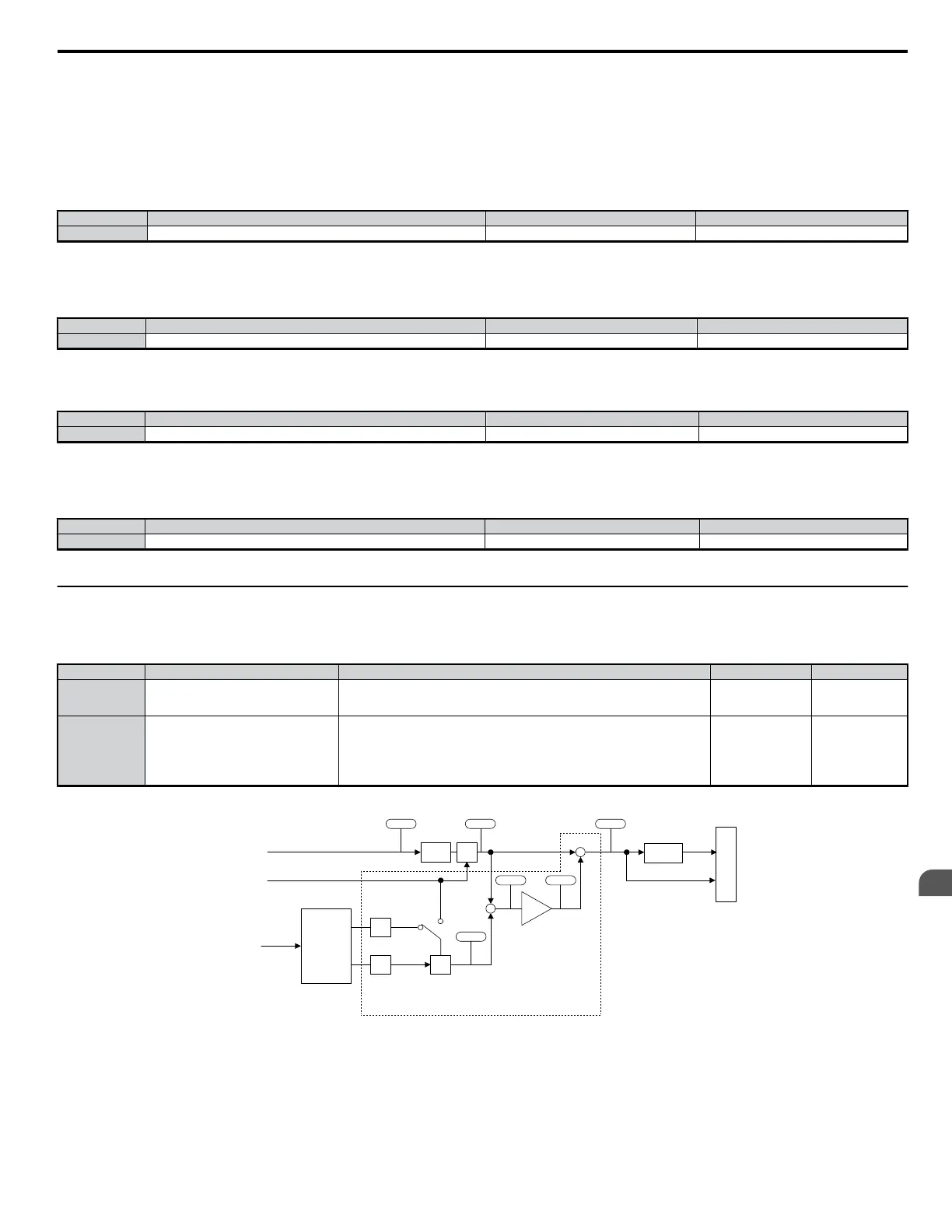

C5: ASR

The automatic speed regulator (ASR) provides optimum performance during changes in motor speed or load by using speed feedback.

Note: C5 parameters will appear only when using V/f Conrol (A1-02 = 0) and the Pulse Train function is set to allow Simple PG in V/f (H6-01 = 3).

No. Parameter Name Setting Range Default Page

A1-02 Control Method Selection

0: V/f Control

2: Open Loop Vector

5: PM Open Loop Vector

0 −

H6-01

Terminal RP Pulse Train Input Function

Selection

Selects the function of pulse train terminal RP.

0: Frequency reference

1: PID feedback value

2: PID setpoint value

3: Motor speed when using Simple PG V/f Control (can be set only when using motor

1 in V/f Control)

0 −

The figure below illustrates how speed control works when using Simple PG in V/f.

Soft

starter

V/f

Conversion

Voltage

Reference

Frequency

Reference

PWM

×

PG/ Pulse

Converter

PI

DI

Frequency

Instruction

Rotation

Direction

Detection

Frequency

Detection

Frequency Detection with sign

ASR

Frequency

Correction

PG Pulse

A/B Signal

U1-01 U1-16

U6-04U6-03

U1-05

C5-01

C5-02

C5-03

C5-04

C5-05

U1-02

×

Positive/

Inverse-instruction

DI Off

DI On

+

_

+

+

Figure 5.26 Speed Control Using Simple V/f with PG

n

C5-01/C5-03: ASR Proportional Gain 1/2 (Simple PG in V/f)

n

C5-02/C5-04:ASR Integral Time 1/2 (Simple PG in V/f)

C5-01 adjusts the speed in response to speed deviation, and softens the effect of changes in load. Speed response increases as the proportional gain is

increased. However, the load may become unstable if the ASR proportional gain is set too high. ASR Proportional Gain 2 is an additional proportional

gain adjustment that can be enabled by either a multi-function contact input (H1-oo = 77) or the ASR switching frequency (C5-07).

5.3 C: Tuning

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

135

5

Parameter Details

Loading...

Loading...