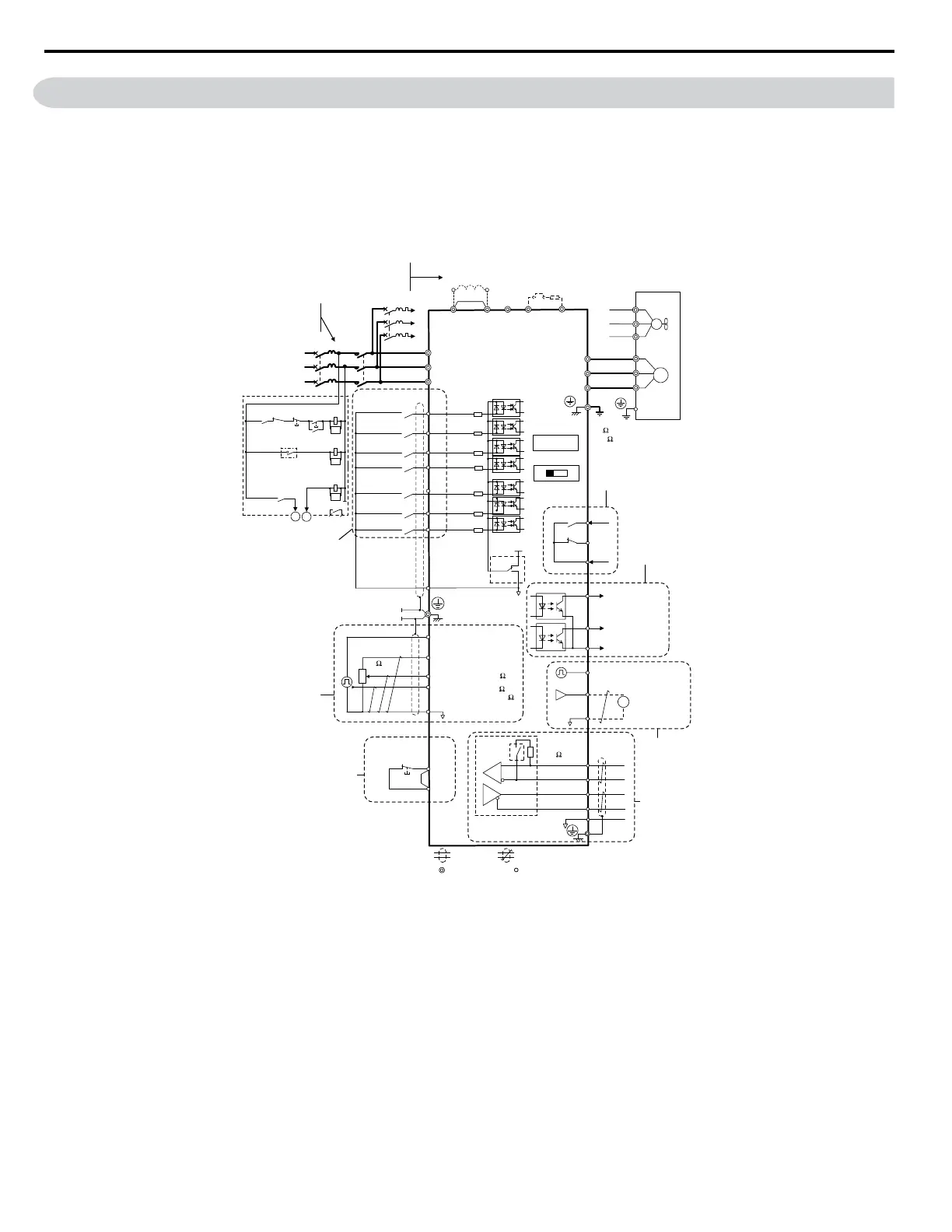

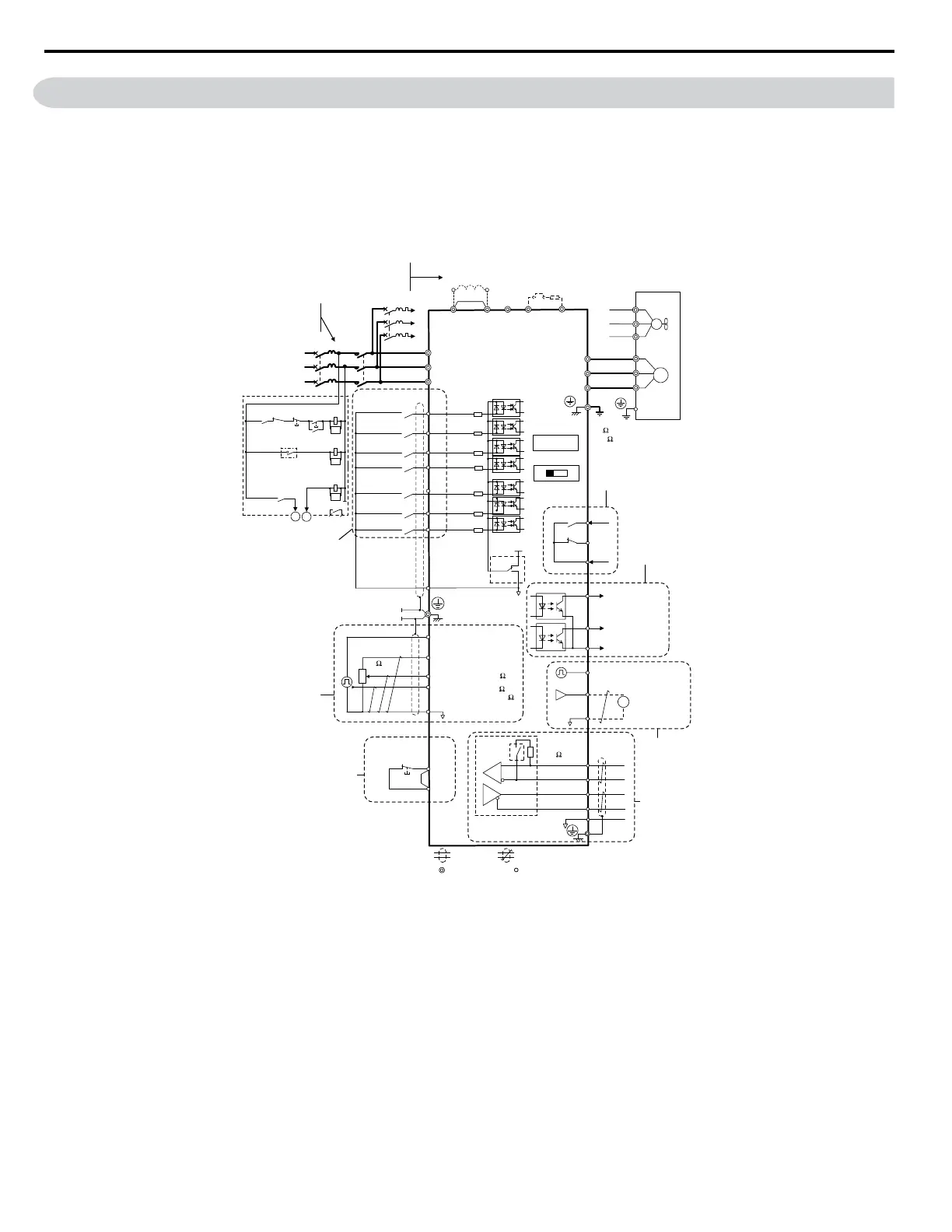

3.2 Standard Connection Diagram

Connect the drive and peripheral devices as shown in

Figure 3.1 . It is possible to run the drive via the digital operator without connecting digital I/O

wiring. This section does not discuss drive operation; Refer to Start-Up Programming & Operation on page 55 for instructions on operating the drive.

NOTICE: Inadequate branch short circuit protection could result in damage to the drive. Install adequate branch circuit short circuit protection per applicable codes. The drive is

suitable for circuits capable of delivering not more than 30,000 RMS symmetrical amperes, 240 Vac maximum (200 V Class) and 480 Vac maximum (400 V Class).

NOTICE: When the input voltage is 480 V or higher or the wiring distance is greater than 100 meters, pay special attention to the motor insulation voltage or use an inverter duty

motor. Failure to comply could lead to motor insulation breakdown.

NOTICE: Do not connect the AC control circuit ground to the drive enclosure. Improper drive grounding can cause the control circuit to malfunction.

NOTICE: The minimum load for the multi-function relay output MA-MB-MC is 10 mA. If a circuit requires less than 10 mA (reference value), connect it to a photocoupler output (P1,

P2, PC). Improper application of peripheral devices could result in damage to the photocoupler output of the drive.

SA

Motor

Cooling fan

Forward run/stop

Reverse run/stop

External fault

Fault reset

Multi-step

speed 2

Jog reference

0 to +10 Vdc

(2 mA)

DIP

switch S3

DC reactor

(option)

Digital inputs

(default setting)

Comm.

connector

Safe Disable

Input

Safety switch

Fault

V1000

Shield ground

terminal

Thermal relay

(option)

Braking resistor

(option)

Main circuit

Control circuit

Thermal relay for

motor cooling fan

Fault relay

1 MCCB

MC

2 MCCB

r1

s1

t1

R/L1

S/L2

T/L3

S1

S2

S3

S4

S5

S6

S7

*3

*

1

*

2

-

B1+1+2 B2

*

4

R/L1

S/L2

T/L3

MC

THRX

TRX

MC

TRX

MC MA

U/T1

V/T2

W/T3

24 V

0 V

MA

P1

MB

MC

V I

+

24 V 8 mA

*

5

M

M

r1

s1

t1

FU

FV

FW

U

V

W

SC

P2

MP

AM

AC

PC

IG

R

+

R

-

S

+

S

-

+

-

AM

HC

H1

RP

+V

A1

A2

AC

*

7

*

6

Pulse train input

(max. 32 kHz)

Ground

10 or less (400 V class)

100 or less (200 V class)

0 to +10 V (20 k )

Setting power supply

+10.5 max. 20 mA

0 to +10 V (20 k )

(0)4 to 20 mA (250 )

For single phase 200 V

power supply, use

R/L1 and S/L2.

During Run

(photocoupler 1)

Frequency agree

(photocoupler 2)

Photocoupler

output common

Digital output

5 ~ 48 Vdc

2 to 50 mA

(default setting)

Pulse train output

0 to 32 kHz

Analog monitor

output

Digital output

250 Vac, 10 mA to 1 A

30 Vdc, 10 mA to 1 A

(default setting)

MEMOBUS/

Modbus comm.

RS-485/422

Main speed

frequency

reference.

Multi-function

programmable

Multi-step

speed 1

main/aux switch

2 MCCB

THRX

OFF

ON

MC

SA

SA

Three phase

power supply

200 to 240 V

Jumper

DIP switch S1

Sink

Source

Termination

resistor

120 , 1/2 W

Terminals +1, +2, , B1, and B2

are for connecting options.

Never connect power supply

lines to these terminals.

_

Monitor

output

*

8

Jumper

Option card

connector

DIP

switch

S2

main circuit terminal

shielded line

twisted-pair shielded line

control terminal

Cable shield ground

2 k

Figure 3.1 Drive Standard Connection Diagram

*1. Remove the jumper when installing an optional DC reactor.

*2. The MC on the input side of the main circuit should open when the thermal relay is triggered.

*3. Self-cooled motors do not require separate cooling fan motor wiring.

*4. Connected using sequence input signal (S1 to S7) from NPN transistor; Default: sink mode (0 V com)

*5. Use only a +24 V internal power supply in sinking mode; the source mode requires an external power supply.

Refer to I/O Connections on page 48.

*6. Minimum load: 5 Vdc, 10mA (reference value)

*7. Monitor outputs work with devices such as analog frequency meters, ammeters, voltmeters and wattmeters; they are intended for use as a feedback-type of signal.

*8. Disconnect the wire jumper between HC and H1 when utilizing the safety input.

WARNING! Sudden Movement Hazard. Do not close the wiring for the control circuit unless the multifunction input terminal parameter is properly set (S5 for 3-wire; H1-05 = “0”).

Improper sequencing of run/stop circuitry could result in death or serious injury from moving equipment.

WARNING! Sudden Movement Hazard. Ensure start/stop and safety circuits are wired properly and in the correct state before energizing the drive. Failure to comply could result

in death or serious injury from moving equipment. When programmed for 3-wire control, a momentary closure on terminal S1 may cause the drive to start.

WARNING! When 3-Wire sequence is used, set the drive to 3-Wire sequence before wiring the control terminals and ensure parameter b1-17 is set to 0 (drive does not accept a

run command at power up (default)). If the drive is wired for 3-Wire sequence but set up for 2-Wire sequence (default) and if parameter b1-17 is set to 1 (drive accepts a Run

command at power up), the motor will rotate in reverse direction at power up of the drive and may cause injury.

3.2 Standard Connection Diagram

34

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

Loading...

Loading...