6.6 Operator Programming Errors

An Operator Programming Error (oPE) occurs when an inappropriate parameter is set or an individual parameter setting is inappropriate.

The drive will not operate until the parameter is set correctly; however, no alarm or fault outputs will occur. If an oPE occurs, investigate the cause and

refer to

Table 6.10 for the appropriate action. When oPE error is displayed, press the ENTER button to display U1-34 (oPE fault constant). This monitor

displays the parameter causing the oPE error.

u

oPE Codes, Causes, and Possible Solutions

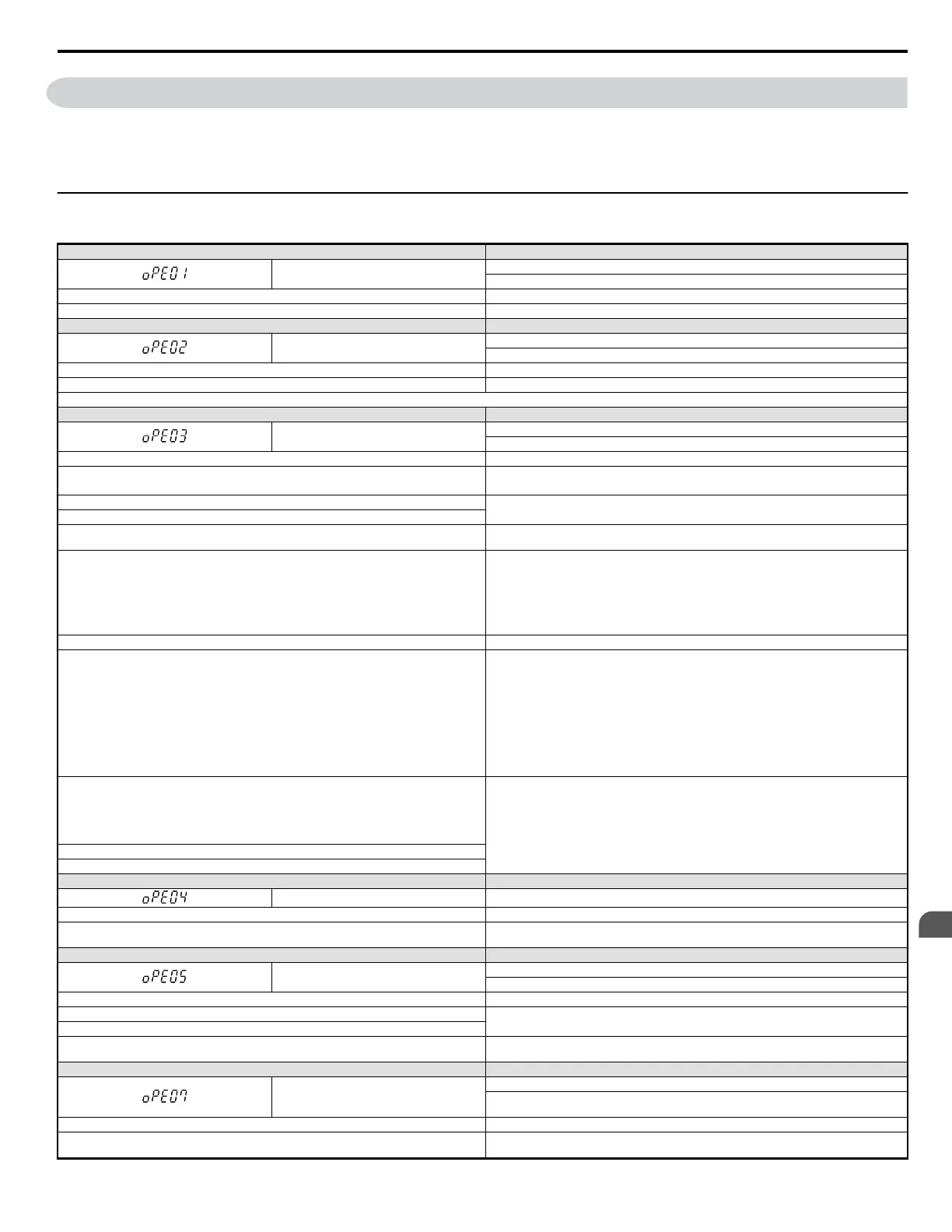

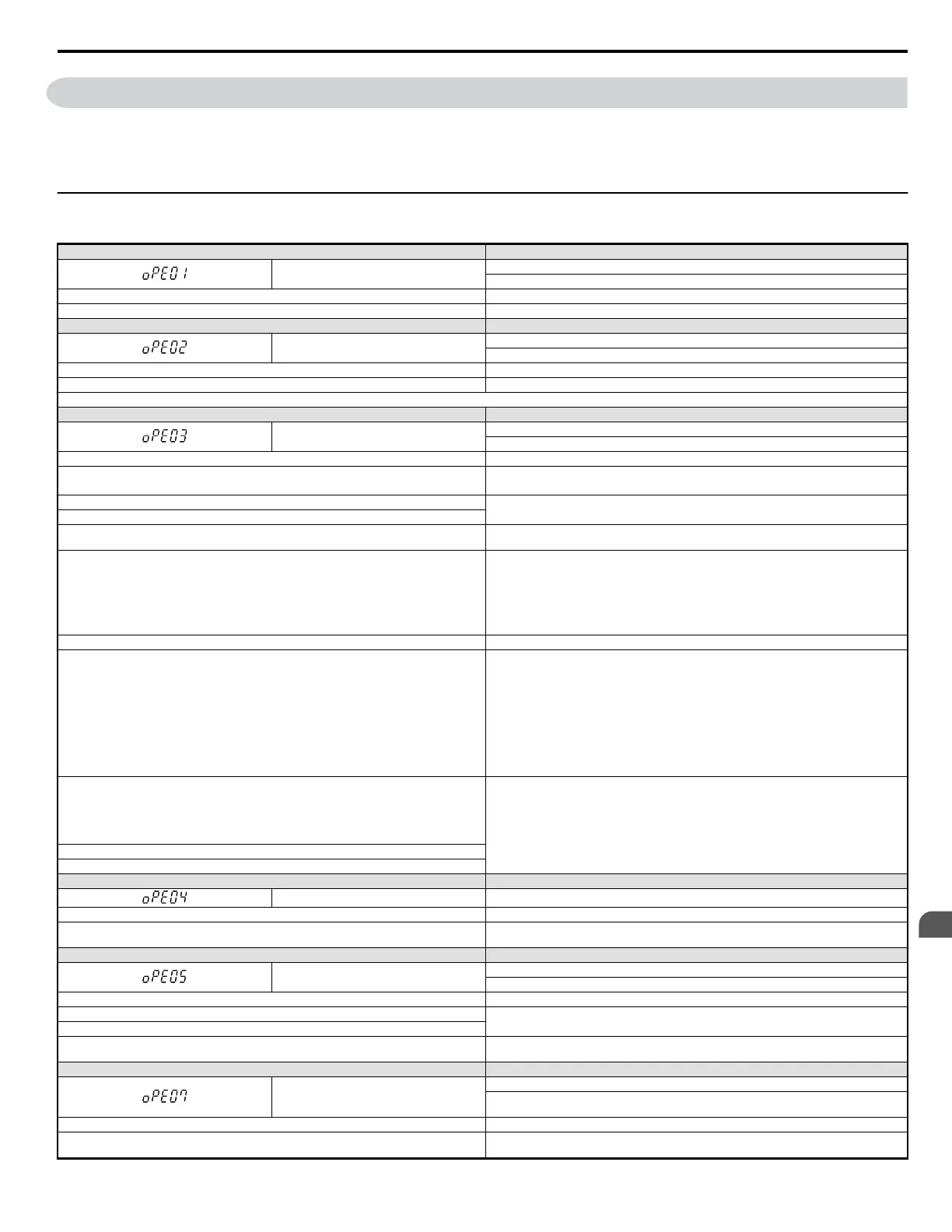

Table 6.10 oPE Codes, Causes, and Possible Solutions

LED Operator Display Error Name

oPE01

Drive Capacity Setting Fault

Drive capacity and then value set to o2-04 do not match.

Cause Possible Solutions

The drive capacity setting (o2-04) and the actual capacity of the drive are not the same. Correct the value set to o2-04.

LED Operator Display Error Name

oPE02

Parameter Range Setting Error

Use U1-18 to find which parameters were set outside the setting range.

Cause Possible Solutions

Parameters were set outside the possible setting range. Set parameters to the proper values.

Note: Other errors are given precedence over oPE02 when multiple errors occur at the same time.

LED Operator Display Error Name

oPE03

Multi-Function Input Selection Error

A contradictory setting is assigned to multi-function contact inputs H1-01 through to H1-07.

Cause Possible Solutions

• The same function is assigned to two multi-function inputs.

• Excludes “Not used” and “External Fault.”

• Ensure all multi-function inputs are assigned to different functions.

• Re-enter the multi-function settings to ensure this does not occur.

The Up command was set but the Down command was not, or vice versa (settings 10 vs. 11).

Correctly set functions that need to be enabled in combination with other functions.

The Up 2 command was set but the Down 2 command was not, or vice versa (settings 75 vs. 76).

Run command for a 2-wire sequence was set, but forward/reverse command for a 2-wire sequence

was not. “Drive Enable” is set to a multi-function contact input (H1-01 = 6A or H1-02 = 6A).

Correctly set functions that need to be enabled in combination with other functions.

Two of the following functions are set at the same time:

• Up / Down Command (10 vs. 11)

• Up 2 / Down 2 Command (75 vs. 76)

• Hold Accel/Decel Stop (A)

• Analog Frequency Reference Sample / Hold (1E)

• Offset Frequency 1, 2, 3 Calculations (44, 45, 46)

• Check if contradictory settings have been assigned to the multi-function input terminals at the

same time.

• Correct setting errors.

The Up/Down command (10, 11) is enabled at the same time as PID control (b5-01). Disable control PID (b5-01 = “0”) or disable the Up/Down command.

One of the following settings at the multi-function input terminals:

• External Search Command 1 and External Search Command 2 (61 vs. 62)

• Fast-Stop N.O. and Fast-Stop N.C. (15 vs. 17)

• KEB for Momentary Power Loss and High Slip Braking (65, 66, 7A, 7B vs. 68)

• Motor Switch Command and Accel/Decel Time 2 (16 vs. 1A)

• KEB Command 1 and KEB Command 2 (65, 66 vs. 7A, 7B)

• FWD Run Command (or REV) and FWD/REV Run Command (2-wire) (40, 41 vs. 42, 43)

• External DB Command and Drive Enable (60 vs. 6A))

• Motor Switch Command and UP2/DOWN2 Command (16 vs. 75, 76)

Check for contradictory settings assigned to the multi-function input terminals at the same

time.Correct setting errors.

One of the following settings was entered while H1-oo = 2 (Alternative Reference):

• b1-15 = 4 (Pulse Train Input) and H6-01 (Pulse Train Input Function Selection) not = 0

(Frequency Reference)

• b1-15 or b1-16 set to 3 but no option card connected

• Although b1-15 = 1 (Analog Input) and H3-02 or H3-10 are set to 0 (Frequency Bias).

Correct the settings for the multi-function input terminal parameters.

H2-oo = 38 (Drive Enabled) but H1-oo is not set to 6A (Drive Enable).

H1-oo = 7E (Direction Detection) although H6-01 is not set to 3 (Simple V/f with PG).

LED Operator Display Error Name

oPE04 Initialization required.

Cause Possible Solutions

The drive, control board, or terminal board has been replaced and the parameter settings between

the control board and the terminal board no longer match.

To load the parameter settings to the drive that are stored in the terminal board, set A1-03 to

5550.Initialize parameters after drive replacement by setting A1-03 to 1110 or 2220.

LED Operator Display Error Name

oPE05

Run Command Selection Error

The Run command selection parameter b1-02 is set to 3 but no option board is installed.

Cause Possible Solutions

Frequency reference is assigned to an option card (b1-01 = 3) that is not connected to the drive.

Reconnect the option card to the drive.

The Run command is assigned to an option card (b1-02 = 3) that is not connected to the drive.

Frequency reference is assigned to the pulse train input (b1-01 = 4), but terminal RP is not set for

pulse train input (H6-01 is greater than 0).

Set H6-01 to “0”.

LED Operator Display Error Name

oPE07

Multi-Function Analog Input Selection Error

A contradictory setting is assigned to multi-function analog inputs H3-02 through to H3-10 and

PID functions conflict.

Cause Possible Solutions

H3-02 and H3-10 are set to the same value.

Change the settings to H3-02 and H3-10 so that functions no longer conflict. Note: Both 0 (primary

analog frequency reference) and F (Not Used) can be set to H3-02 and H3-10 at the same time.

6.6 Operator Programming Errors

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

243

6

Troubleshooting

Loading...

Loading...