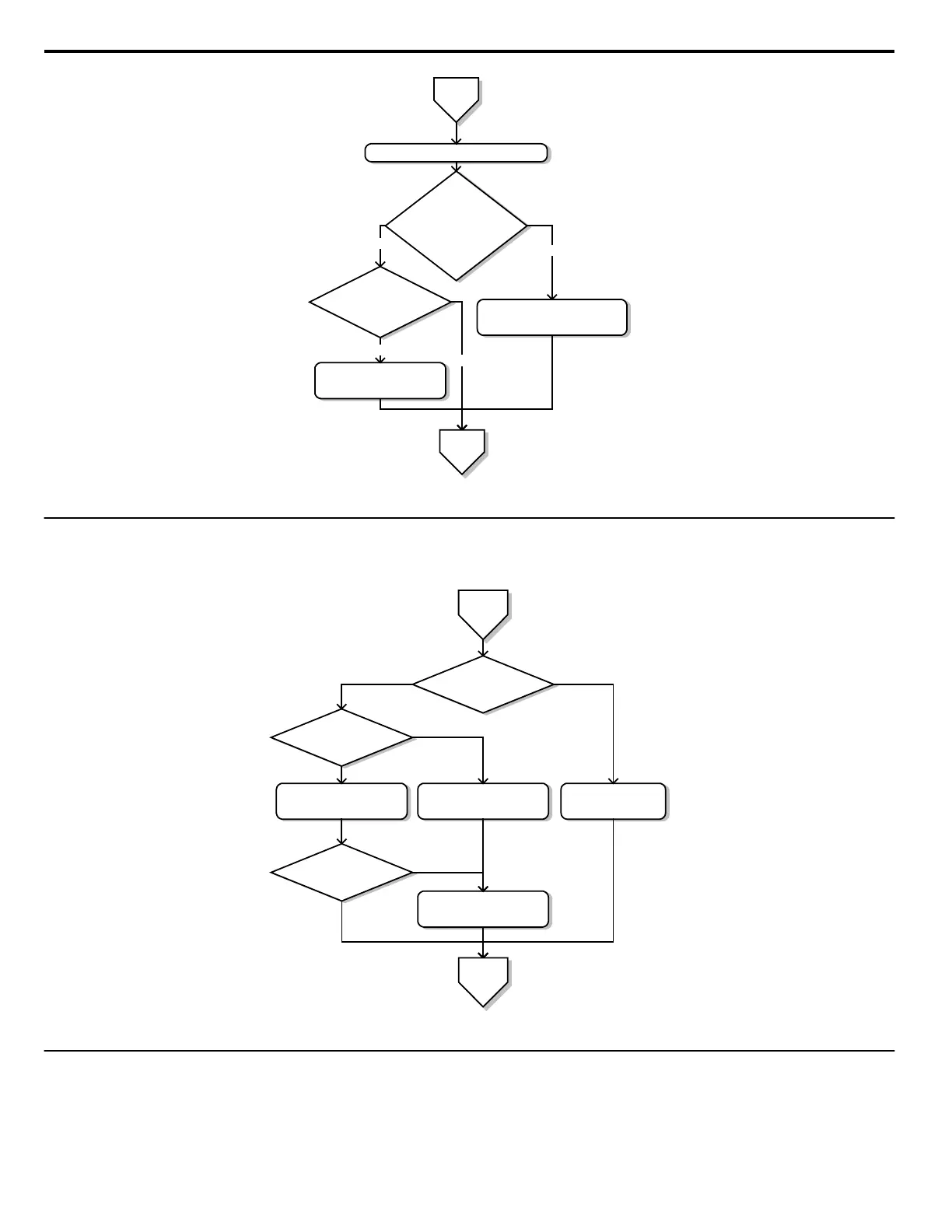

From

Flowchart

A

Set or verify the V/f pattern settings E1-oo.

Energy Savings

(b8-01=1)

or

Speed Estimation

Speed Search (b3-24=1)

enabled ?

Is the motor cable

longer than 50 m?

Perform Rotational Auto-Tuning

for V/f Control

(T1-01 = 3)

NO

YES

Perform Stationary Auto-Tuning for

terminal resistance (T1-01 = 2)

YES

NO

Return to

Flowchart

A

Figure 4.7 Simple Motor Set-Up with Energy Savings or Speed Search Using V/f Mode

u

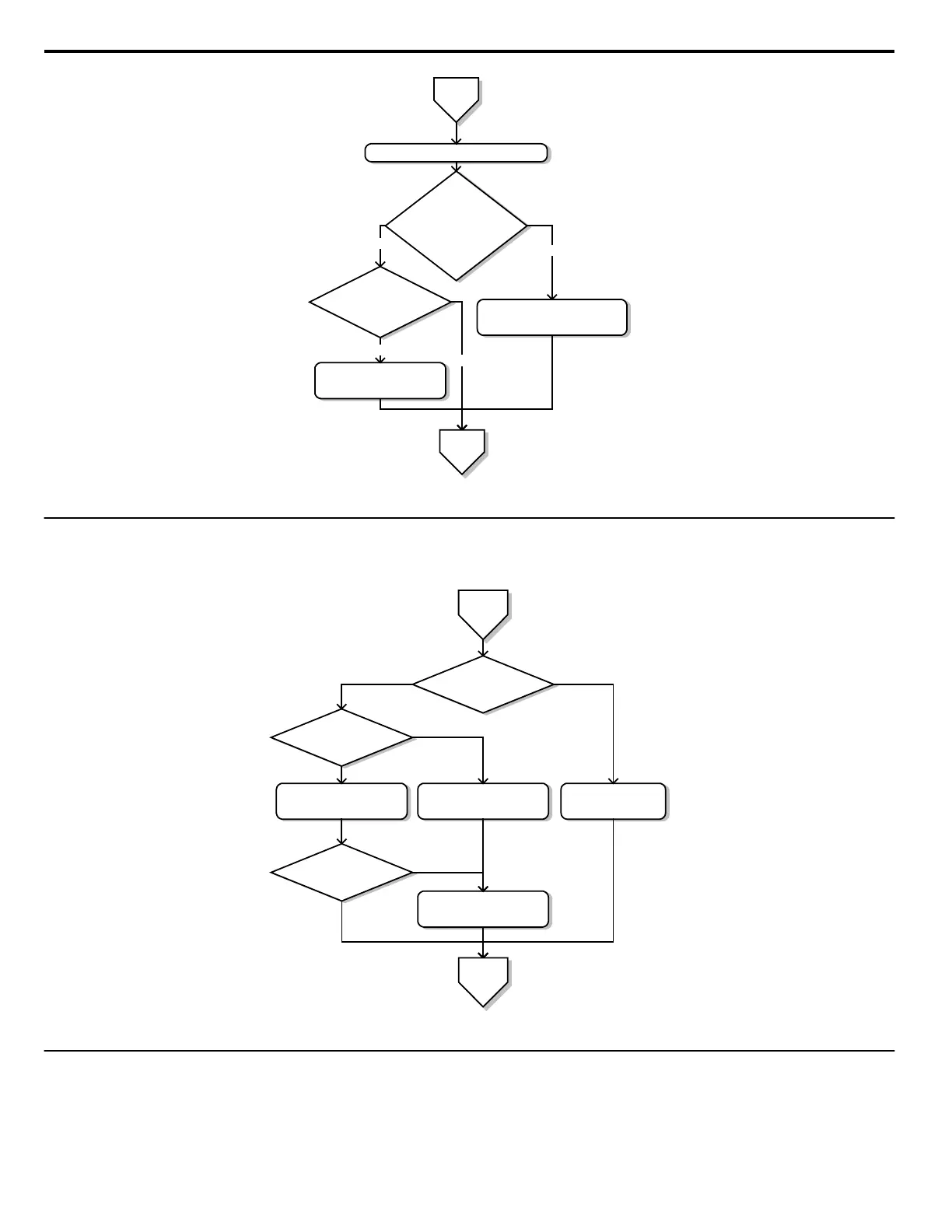

Subchart A2: High Performance Operation Using Open Loop Vector Motor Control

Figure 4.8 , Flowchart A2, uses Open Loop Vector Control for high-performance motor operation. This is appropriate for applications requiring high

starting torque, torque limits, and improved speed regulation.

From

Flowchart

A

Possible for motor to

rotate during tuning? *

Perform Rotating Auto-

Tuning (T1-01 = 0)

Is the motor cable

longer than 50 m?

Perform Stationary Auto-Tuning for

terminal resistance (T1-01 = 2)

*Rotational tuning should

be performed with the

load disconnected

NO YES

NO

Motor test report/ data

sheet available?

Enter the data from the motor data

sheet to E2-oo parameters.

NO

Calculate necessary E2-oo

parameter data using the

nameplate information.

YES

YES

Return to

Flowchart

A

Figure 4.8 Flowchart A2: High Performance Operation Using Open Loop Vector Motor Control

u

Subchart A3: Operation with Permanent Magnet Motors

Figure 4.9 , Flowchart A3, illustrates tuning for PM motors in Open Loop Vector Control. PM motors can be used for energy savings in reduced or

variable torque applications.

4.4 Start-up Flowcharts

68

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

Loading...

Loading...