6.9 Troubleshooting Without Fault Display

This section is for troubleshooting problems that do not trip an alarm or fault.

u

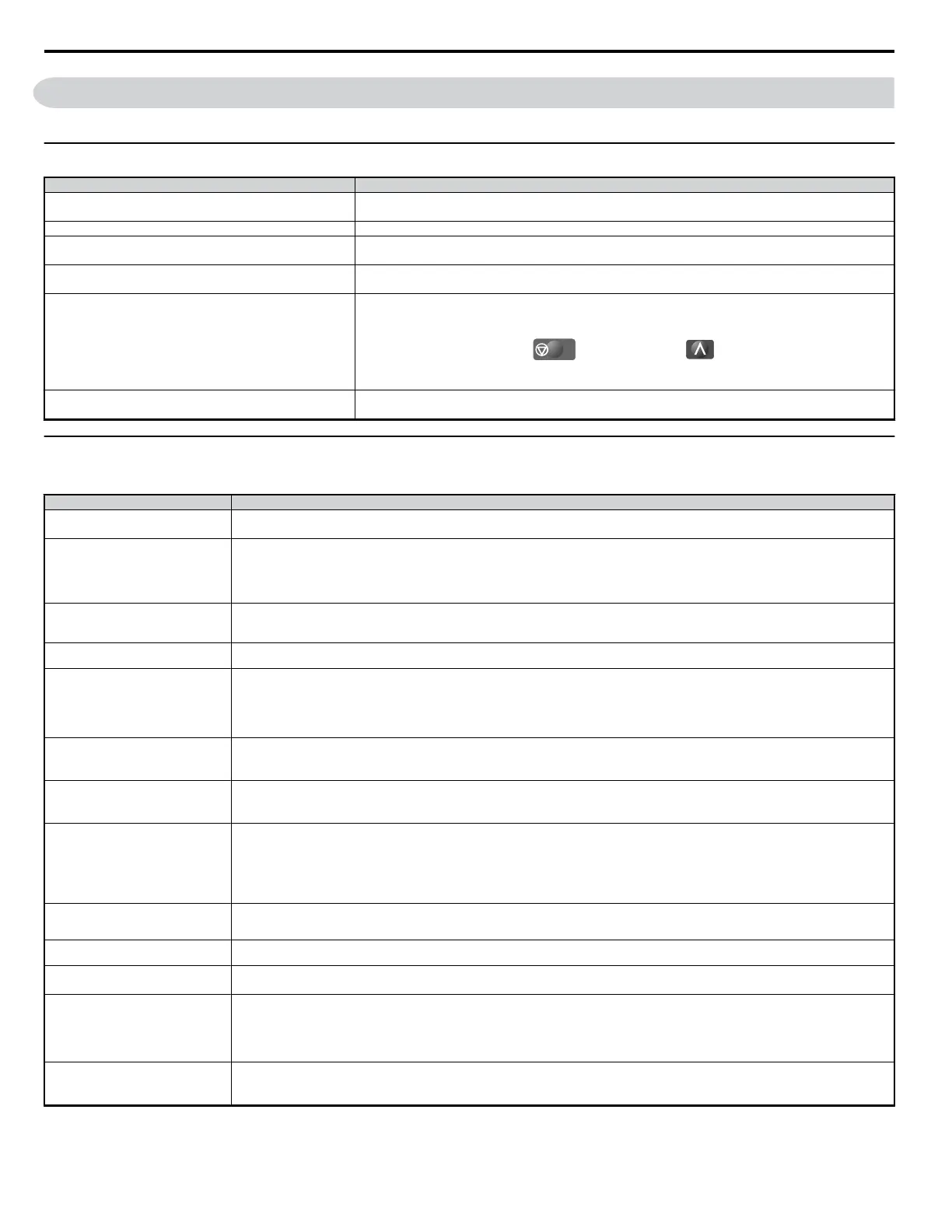

Cannot Change Parameter Settings

Cause Possible Solutions

The drive is running the motor (i.e., the Run command is present).

• Stop the drive and switch over to the Programming Mode.

• Most parameters cannot be edited during run.

The Access Level is set to restrict access to parameter settings. • Set the Access Level to allow parameters to be edited (A1-02 = 2).

The operator is not in the Parameter Setup Mode (the LED screen will

display “PAr”).

• See what mode the LED parameter is current set for.

• Parameters cannot be edited when in the Setup Mode (“STUP”). Switch modes so that “PAr” appears on the screen.

A multi-function contact input terminal is set to allow or restrict

parameter editing (H1-01 through H1-10 = 1B).

• When the terminal is open, parameters cannot be edited.

• Turn on the multi-function contact input set to 1B.

The wrong password was entered.

• If the password entered to A1-04 does not match the password saved to A1-05, then drive settings cannot be changed.

• Reset the password.

If you cannot remember the password:

•

Display parameter A1-04. Press the

STOP

button while pressing at the same time. Parameter A1-05 will

appear.

• Set a new password to parameter A1-05.

Undervoltage was detected.

• Check the drive input power voltage by looking at the DC bus voltage (U1-07).

• Check all main circuit wiring.

u

Motor Does Not Rotate Properly after Pressing RUN Button or After Entering External Run Command

n

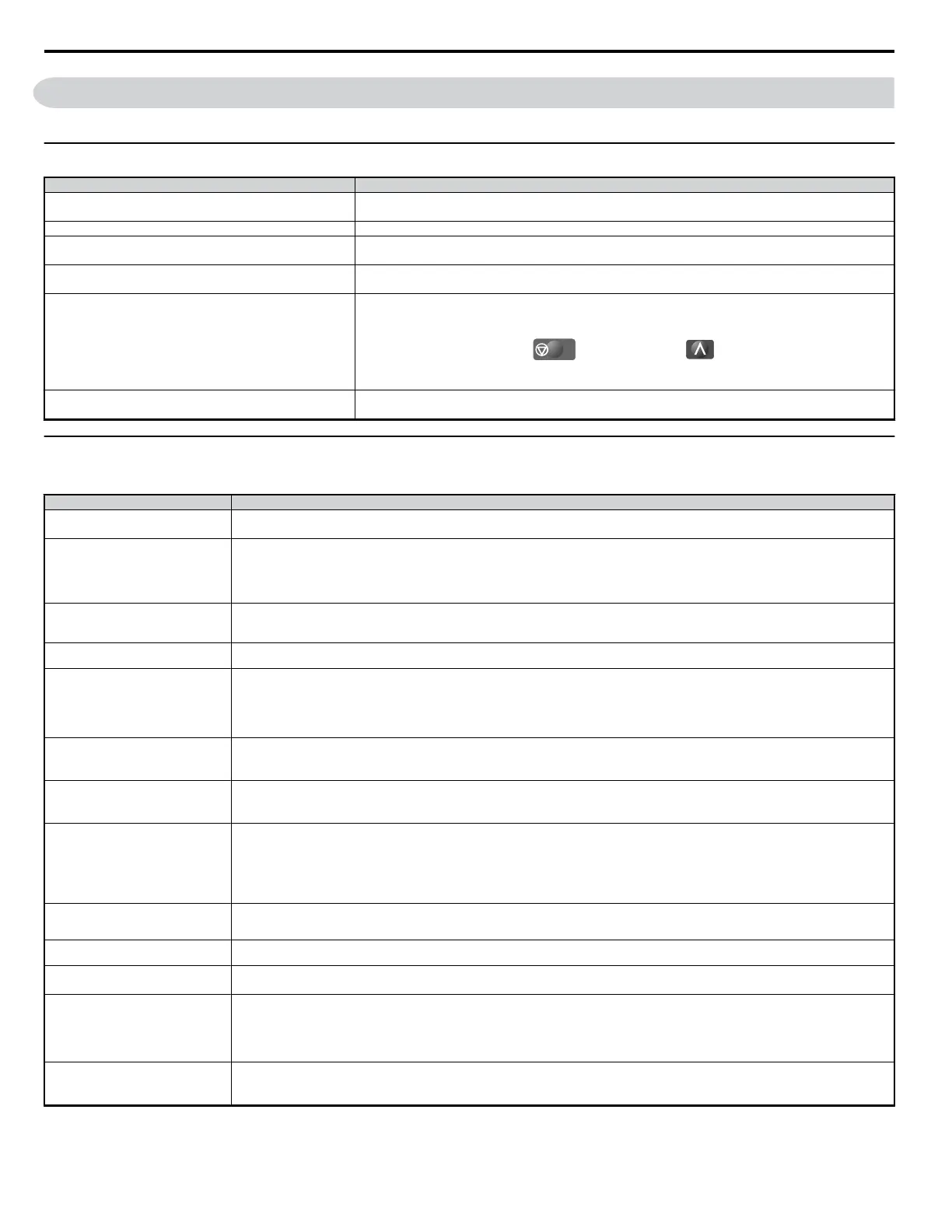

Motor Does Not Rotate

Cause Possible Solutions

The drive is not in the Drive Mode.

• Check if the DRV light on the LED operator is lit.

• Enter the Drive Mode to begin operating the motor. Refer to The Drive and Programming Modes on page 61.

The LO/RE button was pushed.

Stop the drive and check if the correct frequency reference source is selected. If the operator keypad shall be the source, the LO/RE button LED must be

on, if the source is REMOTE, it must be off.

Take the following steps to solve the problem:

• Push the LO/RE button.

• If o2-01 is set to 0, then the LO/RE button will be disabled.

Auto-Tuning has just completed.

• When Auto-Tuning has completed, the drive is switched back to the Programming Mode. The Run command will not be accepted unless the drive is

in the Drive Mode.

• Use the LED operator to enter the Drive Mode. Refer to The Drive and Programming Modes on page 61.

A Fast-Stop was executed and has not yet

been reset.

Reset the Fast-Stop command.

Settings are incorrect for the source that

provides the run command.

Check parameter b1-02 (Run Command Selection).

Set b1-02 so that it corresponds with the correct run command source.

0: LED/LCD operator

1: Control circuit terminal (default setting)

2: MEMOBUS/Modbus communications

3: Option card

One of the Safety Inputs is open.

• Check for a short-circuit between terminals H1 and HC.

• See if one of the Safety Inputs is open.

• Correct any faulty wiring.

There is faulty wiring in the control circuit

terminals.

• Check the wiring for the control terminal.

• Correct wiring mistakes.

• Check the input terminal status monitor (U1-10).

The drive has been set to accept the

frequency reference from the incorrect

source.

Check parameter b1-01 (Frequency Reference Selection 1).

Set b1-01 to the correct source of the frequency reference.

0: LED operator

1: Control circuit terminal (default setting)

2: MEMOBUS/Modbus communications

3: Option card

4: Pulse train input (RP)

The terminal set to accept the main speed

reference is set to the incorrect voltage and/

or current.

Check DIP switch S1. Next assign the correct input level to terminal A2 (H3-09). Refer to Terminal A2 Switch on page 50.

Selection for the sink/source mode is

incorrect.

Check DIP switch S3. Refer to Sinking/Sourcing Mode Switch on page 48.

Frequency reference is too low.

• Check the frequency reference monitor (U1-01).

• Increase the frequency by changing the maximum output frequency (E1-09).

Multi-function analog input is set up to

accept gain for the frequency reference,

but no voltage (current) has been provided.

• Check the multi-function analog input settings.

• Check if analog input A1 or A2 is set for frequency reference gain (H3-02/10 = 1). If so, check if the correct signal is applied to the terminal. The gain

and the frequency reference will be 0 if no signal is applied to the gain input.

• Check if H3-02 and H3-10 have been set to the proper values.

• Check if the analog input value has been set properly.

The STOP button was pressed when the

drive was started from a REMOTE source.

• When the STOP button is pressed, the drive will decelerate to stop.

• Switch off the run command and then re-enter a run command.

• The STOP button is disabled when o2-02 is set to 0.

6.9 Troubleshooting Without Fault Display

248

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

Loading...

Loading...