6.2 Motor Performance Fine Tuning

This section offers helpful information for counteracting oscillation, hunting, or other faults that occur while performing a trial run. Refer to the section

below that corresponds to the motor control method used.

Note: This section describes parameters that are commonly edited. Consult Yaskawa for more information on detailed settings and fine-tuning the drive.

u

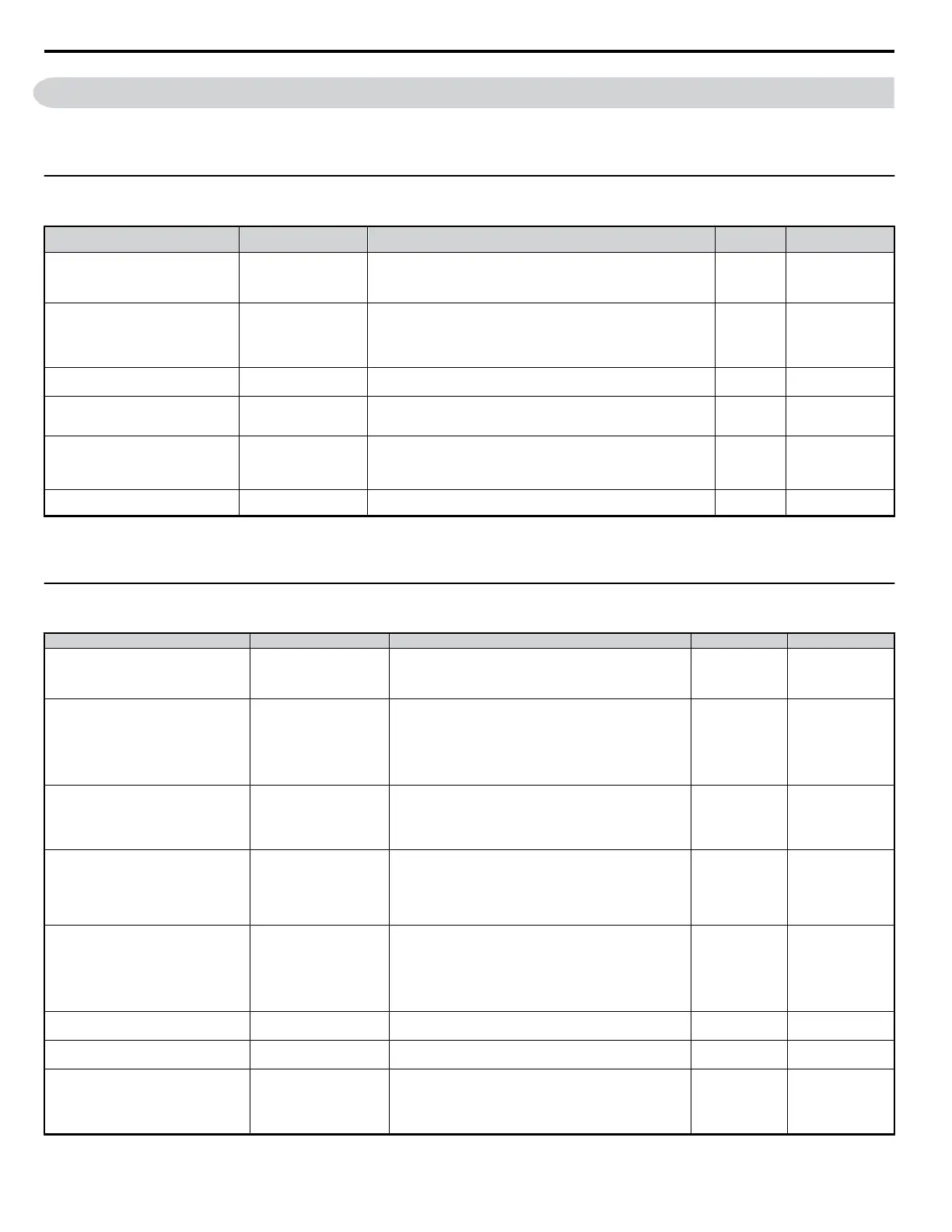

V/f Motor Control Method Tuning

Table 6.1 Parameters for Tuning the Drive in V/f Motor Control Method

Problem Parameter No. Countermeasure

Default

Value

Suggested Setting

• Motor hunting and oscillation at speeds

between 10 and 40 Hz

Hunting Prevention Gain

(n1-02)

• If insufficient motor torque relative to the size of the load causes hunting,

reduce the setting.

• When motor hunting and oscillation occur with a light load, increase the

setting.

1.00 0.50 to 2.00

• Motor noise

• Motor hunting and oscillation at speeds

up to 40 Hz

Carrier Frequency Selection

(C6-02)

• If the motor noise is too loud, increase the carrier frequency.

• When motor hunting and oscillation occur at speeds up to 40 Hz, lower the

carrier frequency.

• The default setting for the carrier frequency depends on the drive capacity (

o2-04) and the Drive Duty Selection (C6-01).

7 (Swing PWM

1)

1 to A

• Poor torque or speed response

• Motor hunting and oscillation

Torque Compensation

Primary Delay Time (C4-02)

• If motor torque and speed response are too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

200 ms <1> 100 to 1000 ms

• Poor motor torque at speeds below 10 Hz

• Motor hunting and oscillation

Torque Compensation Gain

(C4-01)

• If motor torque is insufficient at speeds below 10 Hz, increase the setting.

• If motor hunting and oscillation with a relatively light load, decrease the

setting.

1.00 0.50 to 1.50

• Poor motor torque at low speeds

• Poor motor instability at motor start

Mid Output Voltage A

(E1-08)

Minimum Output Voltage

(E1-10)

• If torque is insufficient at speeds below 10 Hz, increase the setting.

• If motor instability occurs at motor start, decrease the setting.

Note: The recommended setting value is for 200 V class drives. Double this

value when using a 400 V class drive.

E1-08: 16.0

VE1-10: 12.0

V

Initial value ±5 V

• Poor speed precision

Slip Compensation Gain

(C3-01)

• After setting the motor-rated torque (E2-01), motor-rated slip (E2-02) and

motor no-load current (E2-03), adjust the slip compensation gain (C3-01).

- 0.5 to 1.5

<1> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03. The default setting shown is for V/f Control.

Note: Use slip compensation to improve speed precision in V/f Control. First make sure that the proper values have been set for the motor rated current to E2-01, motor rated slip

(E2-02), and motor no-load current (E2-03). Next, adjust the slip compensation gain set to C3-01 so that it is between 0.5 to 1.5.

u

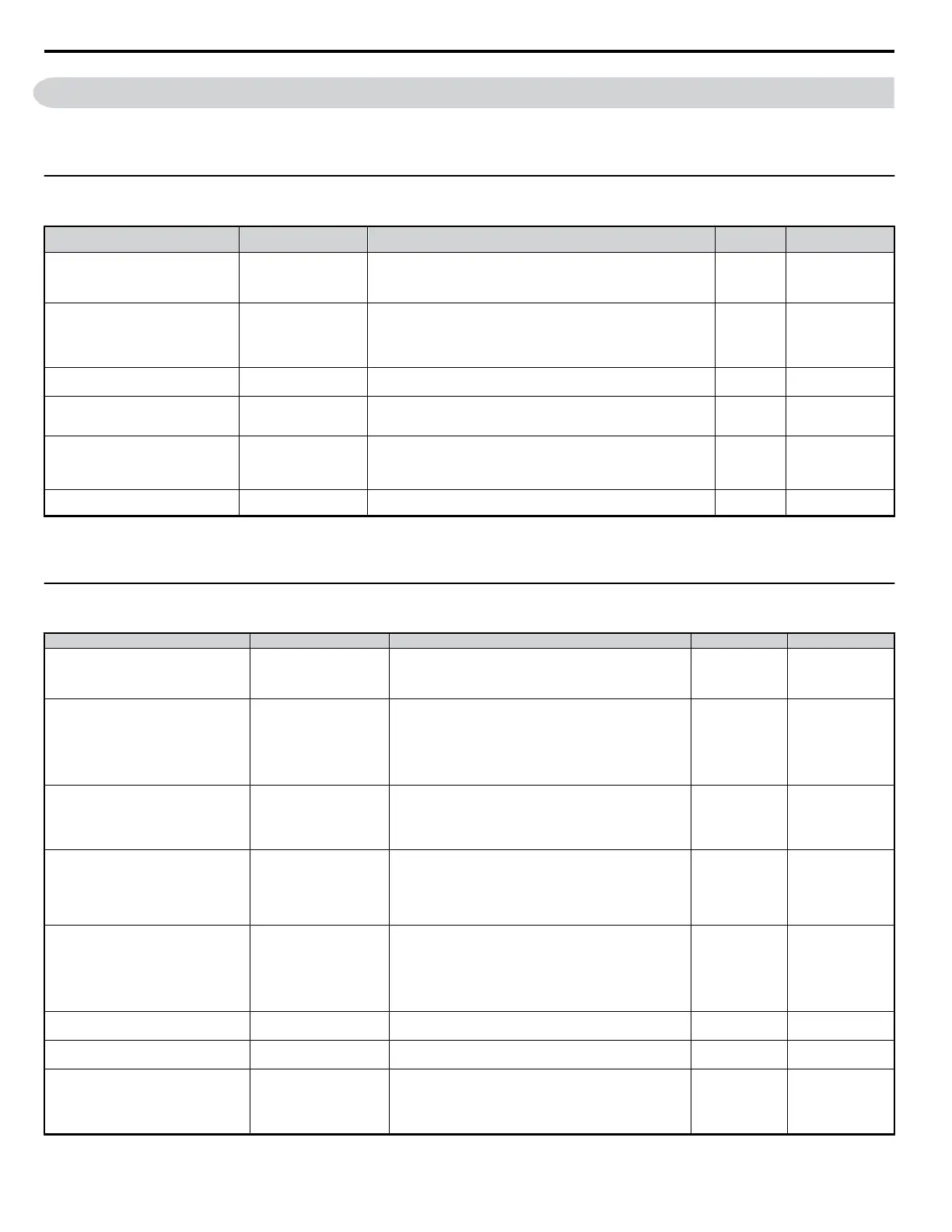

Open Loop Vector (OLV) Motor Control Method Tuning

Table 6.2 Parameters for Tuning the Drive in OLV Motor Control Method

Problem Parameter No. Countermeasure Default Value Suggested Setting

• Poor motor torque and speed response

• Control motor hunting and oscillation at

speeds between 10 and 40 Hz.

AFR Gain

(n2-01)

• If motor torque and speed response are too slow, gradually

decrease the setting by 0.05.

• If motor hunting and oscillation occur, gradually increase the

setting by 0.05.

1.00 0.50 to 2.00

• Poor motor torque and speed response

• Control motor hunting and oscillation at

speeds between 10 and 40 Hz.

AFR Time Constant 1

(n2-02)

• To improve motor torque speed response, gradually reduce this

setting by 10 ms and check the performance.

• If motor hunting and oscillation occur as a result of load inertia,

gradually increase the setting by 50 ms and check the performance.

Note: Ensure that n2-02 ≤ n2-03. When making adjustments to n2-02,

set C4-02 (Torque Compensation Primary Delay Time Constant 1)

accordingly.

50 ms 50 to 2000 ms

• Overvoltage trips when accelerating,

decelerating, or during sudden speed or load

changes.

AFR Time Constant 2

(n2-03)

• If overvoltage trips occur, gradually increase this setting by 50 ms.

• If response is slow, gradually reduce this setting by 10 ms.

Note: Ensure that n2-02 ≤ n2-03. When making adjustments to n2-03,

increase the value of C4-06 (Torque Compensation Primary Delay

Time 2) proportionally.

750 ms 750 to 2000 ms

• Poor motor torque and speed response

• Motor hunting and oscillation.

Torque Compensation Primary

Delay Time Constant 1

(C4-02)

• To improve motor torque speed response, gradually reduce this

setting by 2 ms and check the performance.

• If motor hunting and oscillation occur, gradually increase this

setting by 10 ms.

Note: Ensure that C4-02 ≤ C4-06. When making adjustments to

C4-02, increase n2-02 (AFR Time Constant) proportionally.

20 ms <1> 20 to 100 ms

• Overvoltage trips when accelerating,

decelerating, or during sudden speed or load

changes

Torque Compensation Primary

Delay Time Constant 2 (C4-06)

• If overvoltage trips occur, gradually increase this setting by 10 ms

and check the performance.

• If response is slow, gradually reduce this setting by 2 ms and check

the performance.

Note: Ensure that C4-02 ≤ C4-06. When changing C4-06 (Torque

Compensation Primary Delay Time Constant 2), increase the value

of n2-03 proportionally.

150 ms 150 to 750 ms

• Poor speed response and stability

Slip Compensation Primary

Delay Time Constant (C3-02)

• If response is slow, gradually decrease the setting by 10 ms.

• If speed is unstable, gradually increase the setting by 10 ms.

200 ms <1> 100 to 500 ms

• Poor speed precision

Slip Compensation Gain

(C3-01)

• If speed is too slow, gradually increase the setting by 0.1 ms.

• If speed is too fast, gradually decrease the setting by 0.1 ms.

1.0 <1> 0.5 to 1.5

• Motor noise

• Control motor hunting and oscillation occur

at speeds below 10 Hz.

Carrier Frequency Selection

(C6-02)

• If there is too much motor noise, the carrier frequency is too high.

• If motor hunting and oscillation occur at low speeds, reduce the

carrier frequency.

• The default setting for the carrier frequency depends on the drive

capacity (o2-04) and Drive Duty Selection (C6-01).

7 (Swing PWM 1) 0 to the default setting

6.2 Motor Performance Fine Tuning

224

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

Loading...

Loading...