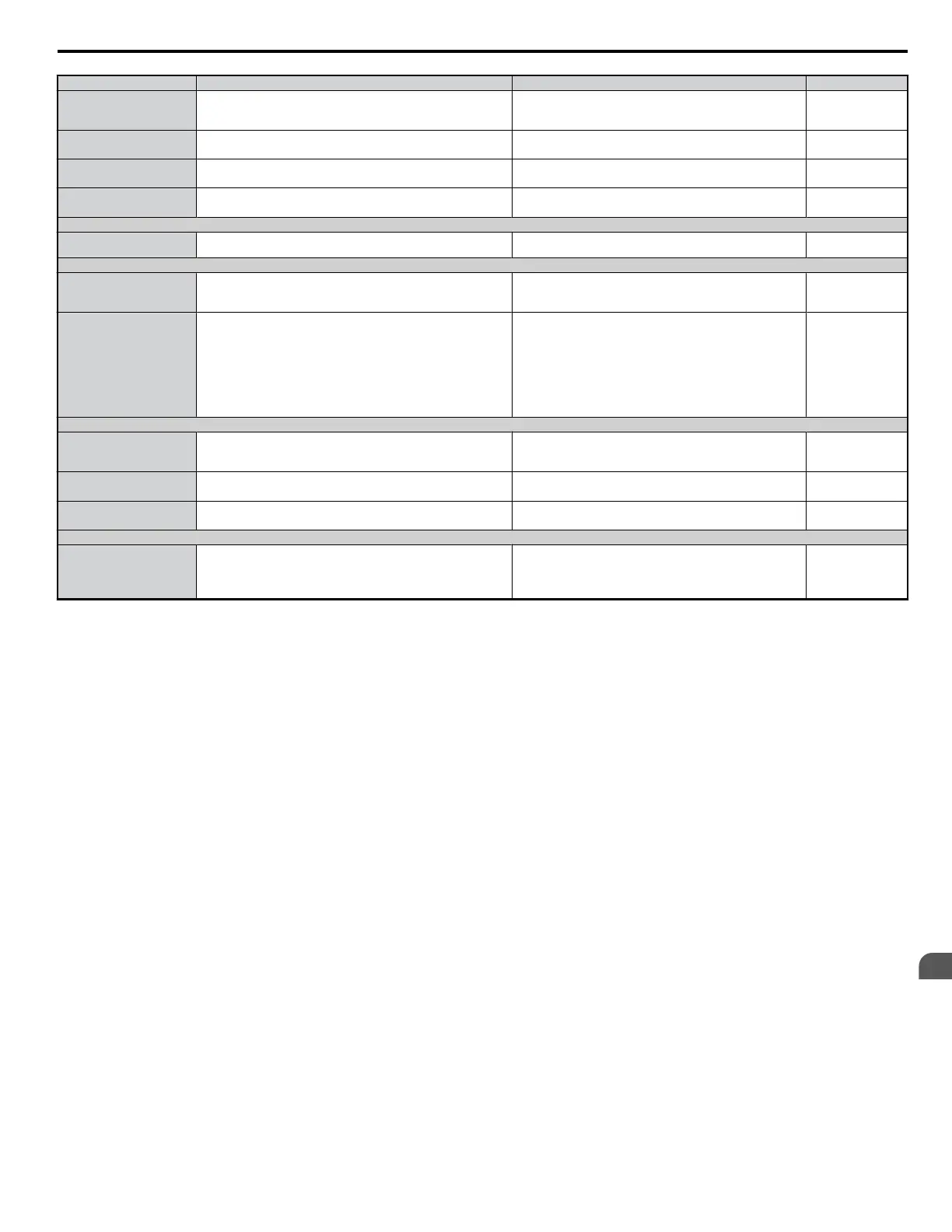

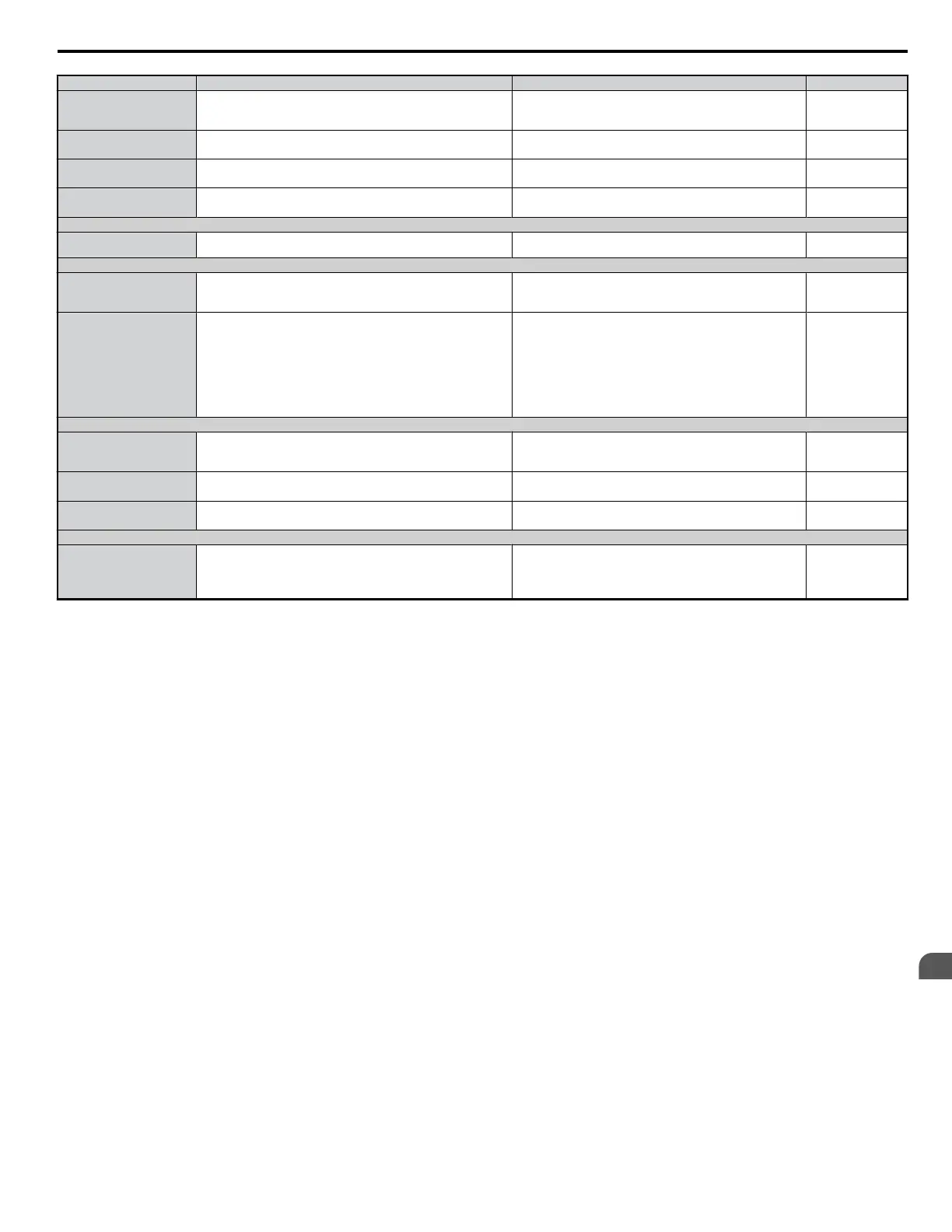

Inspection Area Inspection Points Corrective Action Checked

Relays and Contactors

• Inspect contactors and relays for excessive noise during operation.

• Inspect coils for signs of overheating such as melted or cracked

insulation.

• Check coil voltage for over or under voltage conditions.

• Replace damaged removable relays contactors or circuit board.

Braking Resistors • Inspect for discoloration of heat stress on or around resistors.

• Minor discoloration may be acceptable.

• If discoloration exists check for loose connections.

Electrolytic (bus) Capacitors

• Inspect for leakage, discoloration, or cracks.

• Inspect the relief valve for swelling, rupture, or leakage.

• The drive has few serviceable parts and may require complete

drive replacement.

Diodes and IGBTs

• Inspect for accumulation of dust or other foreign particles on

components.

• Use dry air to clear away foreign matter.

•

Use a pressure of: 39.2 x 10

4

to 58.8 x 10

4

Pa (4 - 6 kg •cm

2

).

Motor Periodic Inspection

Operation Check • Check for increased vibration or abnormal noise.

• Stop the motor and contact qualified maintenance personnel as

required.

Control Circuit Periodic Inspection

General

• Inspect terminals for stripped, damaged or loose connections.

• Check for tightness.

• Tighten loose screws and replace damaged screws or terminals.

• If terminals are integral to a circuit board then board or drive

replacement may be required.

Printed Circuit Boards

• Inspect for unusual discoloration, burning or strange odor, noticeable

rust or corrosion, proper seating of connectors, dust, oil, or other

contamination.

• Re-seat loose connectors.

• Replace PCBs if wiping or vacuuming with anti-static vacuum

cannot clean the PCB.

• Do not use solvents on PCBs.

• Use dry air to clear away foreign matter. Use a pressure of 39.2

x 10

4

to 58.8 x 10

4

Pa (4 - 6 kg •cm

2

).

• The drive has few serviceable parts and may require complete

drive replacement.

Cooling System Periodic Inspection

Cooling Fan

• Check for abnormal oscillation or unusual noise.

• Check for damaged or missing fan blades.

• Replace as required.

• Refer to Drive Cooling Fans on page 261 for information on

cleaning or replacing the cooling fan.

Heatsink • Inspect for dust or other foreign material collected on the surface.

• Use dry air to clear away foreign matter.

•

Use a pressure of 39.2 x 10

4

to 58.8 x 10

4

Pa (4 - 6 kg•cm

2

).

Air Duct

• Inspect air intake and exhaust openings. They must be free from

obstruction and properly installed.

• Visually inspect the area.

• Clear obstructions and clean air duct as required.

LED Periodic Inspection

LEDs

• Make sure the LED lights correctly.

• Make sure various components operate properly.

• Inspect for dust or other foreign material that may have collected on

surrounding components.

• Contact your Yaskawa representative if there is any trouble with

the LED or keypad.

• Clean the LED.

Note: Periodic inspections should be performed every one or two years. The drive, however, may require more frequent inspection due to poor environments or rigorous use.

7.2 Inspection

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

259

7

Periodic Inspection &

Maintenance

Loading...

Loading...