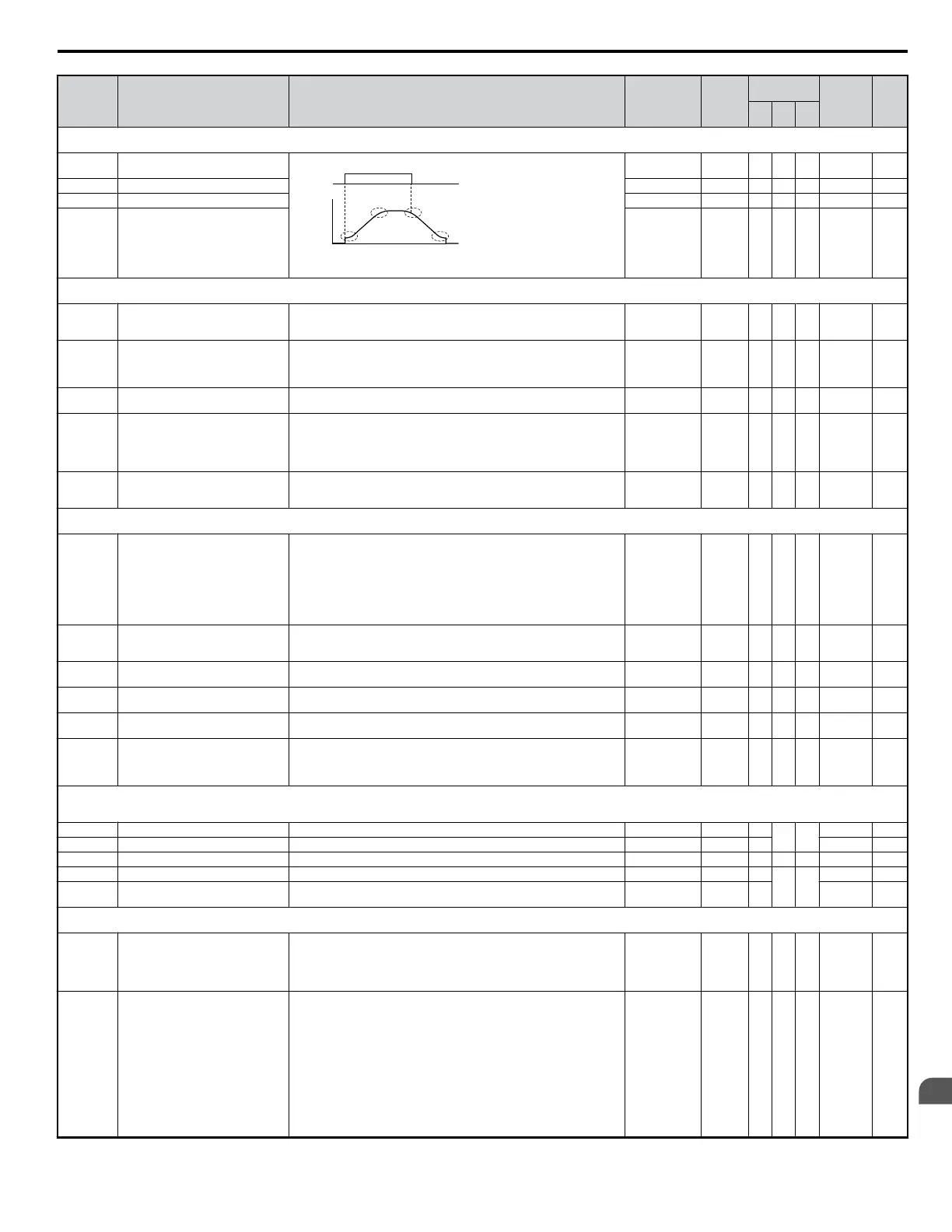

No. Name Description Range Def.

Control

Mode

Addr.

Hex

Pg.

V/f

OL

V

PM

C2: S-Curve Characteristics

Use C2 parameters to configure S-curve operation.

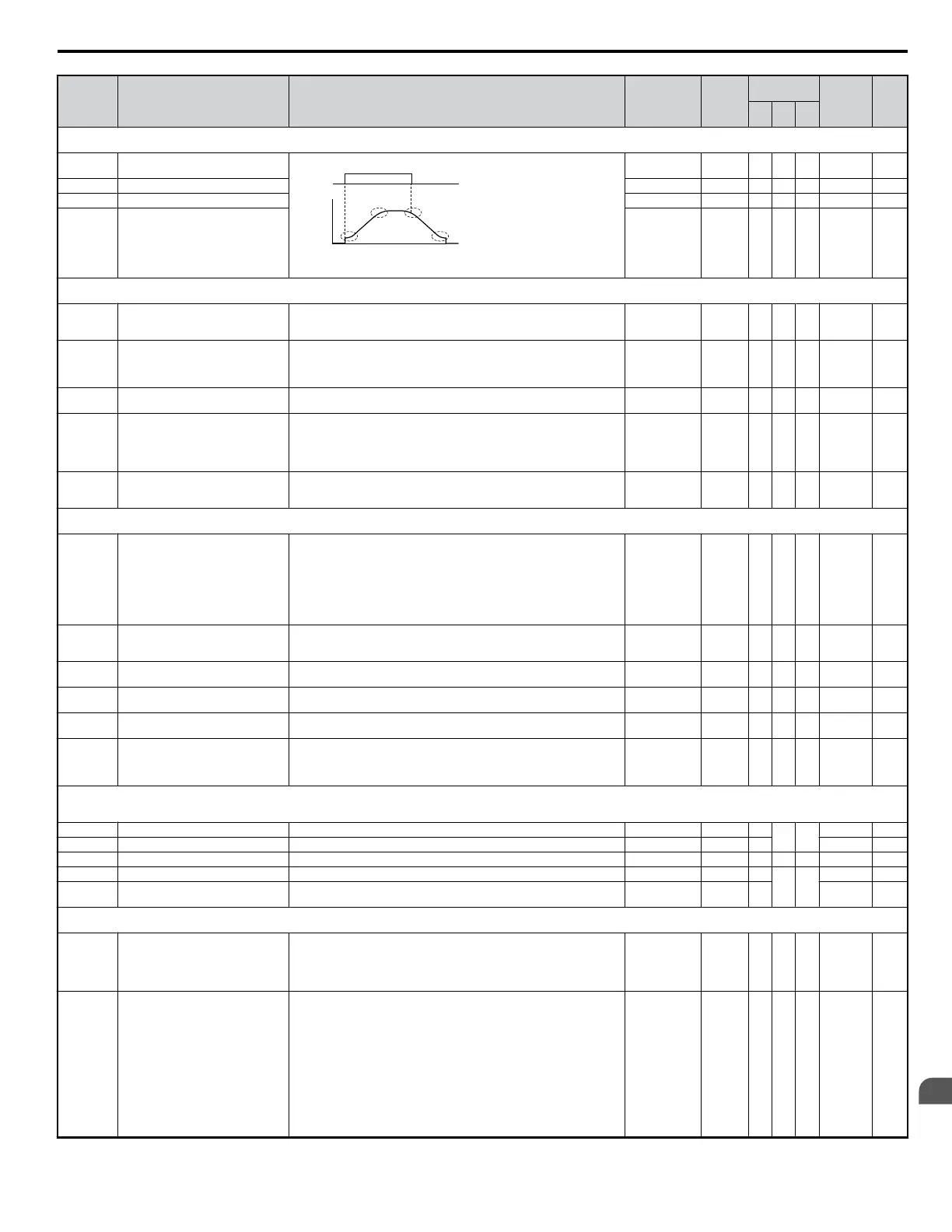

C2-01 S-Curve Characteristic at Accel Start

The S-curve can be controlled in the four points shown below.

time

run

command

output

frequency

C2-01 C2-04

C2-02 C2-03

ON

OFF

S-curve is used to further soften the starting and stopping ramp. The longer

the S-curve time, the softer the starting and stopping ramp.

0.00 to 10.00

0.20 s

<2>

A A A 20B —

C2-02 S-Curve Characteristic at Accel End 0.00 to 10.0 0.20 s A A A 20C —

C2-03 S-Curve Characteristic at Decel Start 0.00 to 10.0 0.20 s A A A 20D —

C2-04 S-Curve Characteristic at Decel End 0.00 to 10.0 0.00 s A A A 20E —

C3: Slip Compensation

Use C3 parameters to configure the slip compensation function.

C3-01 <22> Slip Compensation Gain

Sets the slip compensation gain. Decides for what amount the output

frequency is boosted in order to compensate the slip.

Note: Adjustment is not normally required.

0.0 to 2.5 0.0 <2> A A − 20F —

C3-02

Slip Compensation Primary Delay

Time

Adjusts the slip compensation function delay time.

Decrease the setting when the slip compensation response is too slow, increase

it when the speed is not stable.

Disabled when Simple V/f Control with PG (H6-01 = 3) is used.

0 to 10000

2000 ms

<2>

A A − 210 —

C3-03 Slip Compensation Limit

Sets the slip compensation upper limit. Set as a percentage of motor rated slip

(E2-02). Disabled when Simple V/f Control with PG (H6-01 = 3) is used.

0 to 250 200% A A − 211 —

C3-04

Slip Compensation Selection during

Regeneration

Selects slip compensation during regenerative operation.

0: Disabled

1: Enabled

Using the Slip Compensation function during regeneration may require a

braking option to handle momentary increasing regenerative energy.

0, 1 0 A A − 212 —

C3-05

Output Voltage Limit Operation

Selection

Selects if the motor magnetic flux is reduced during output voltage saturation.

0: Disabled

1: Enabled

0, 1 0 <2> − A − 213 —

C4: Torque Compensation

Use C4 parameters to configure Torque Compensation function.

C4-01 <23> Torque Compensation Gain

V/f control: Sets the gain for the automatic torque (voltage) boost function

and helps to produce better starting torque.

Increase this setting when using a long motor cable or when the motor is

significantly smaller than the drive capacity.

Decrease this setting when motor oscillation occurs. Set the value so that the

current at low speed does not exceeds the drives rated current.

Open Loop Vector: Sets the torque compensation function gain. Normally no

change is required.

0.00 to 2.50 1.00 A A A 215 —

C4-02

Torque Compensation Primary Delay

Time

Sets the torque compensation filter time.

Increase this setting when motor oscillation occurs.

Reduce the setting if there is not enough response from the motor.

0 to 60000

200 ms

<1>

A A A 216 —

C4-03

Torque Compensation at Forward

Start

Sets torque compensation at forward start as a percentage of motor torque. 0.0 to 200.0 0.0% − A − 217 —

C4-04

Torque Compensation at Reverse

Start

Sets torque compensation at reverse start as a percentage of motor torque. -200.0 to 0.0 0.0% − A − 218 —

C4-05 Torque Compensation Time Constant

Sets the time constant for torque compensation at forward start and reverse

start (C4-03 and C4-04). The filter is disabled if the time is set to 4 ms or less.

0 to 200 10 ms – A – 219 —

C4-06

Torque Compensation Primary Delay

Time 2

Sets the torque compensation time 2. When an OV fault occurs with sudden

load changes or at the and of an acceleration, increase the setting.

Note: Adjustment is not normally required. If adjusted then AFR time 2

(n2-03) should be adjusted too.

0 to 10000 150 ms – A – 21AH —

C5: Speed Control (ASR)

Use C5 parameters to configure the Automatic Speed Regulator (ASR).

C5 parameters are available only when using V/f with Simple PG (H6-01 = 3).

C5-01 <22> ASR Proportional Gain 1 Sets the proportional gain of the speed control loop (ASR). 0.00 to 300.00 0.20 A

– –

21B —

C5-02 <22> ASR Integral Time 1 Sets the integral time of the speed control loop (ASR). 0.000 to 10.000 0.200 s A 21C —

C5-03 <22> ASR Proportional Gain 2 Sets the speed control gain 2 of the speed control loop (ASR). 0.00 to 300.00 0.02 A − − 21D —

C5-04 <22> ASR Integral Time 2 Sets the integral time 2 of the speed control loop (ASR). 0.000 to 10.000 0.050 s A

– –

21E —

C5-05 <22> ASR Limit

Sets the upper limit for the speed control loop (ASR) as a percentage of the

maximum output frequency (E1-04).

0.0 to 20.0 5.0% A 21F —

C6: Carrier Frequency

Use C6 parameters to configure the carrier frequency drive settings.

C6-01 Normal/Heavy Duty Selection

Selects the load rating for the drive.

0: Heavy Duty (HD) for constant torque applications.

1: Normal Duty (ND) for variable torque applications.

This setting affects the Rated output current and overload tolerance of the

drive.

0, 1 1 S S S 223 82

C6-02 Carrier Frequency Selection

Selects the carrier frequency

1 : 2.0 kHz

2 : 5.0 kHz

3 : 8.0 kHz

4 : 10.0 kHz

5 : 12.5 kHz

6 : 15.0 kHz

7 : Swing PWM1 (Audible sound 1)

8 : Swing PWM2 (Audible sound 2)

9 : Swing PWM3 (Audible sound 3)

A : Swing PWM4 (Audible sound 4)

B to E: No setting possible

F : User defined (determined by C6-03 through C6-05)

1 to F <3> S S S 224 82

B.2 Parameter Table

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

299

B

Parameter List

Loading...

Loading...