215676 428 Revision A

3. Move the platform on the left cab-forward side of the machine to the open position. For instructions, refer to 5.4.1

Opening Platforms – Standard Position, page 319.

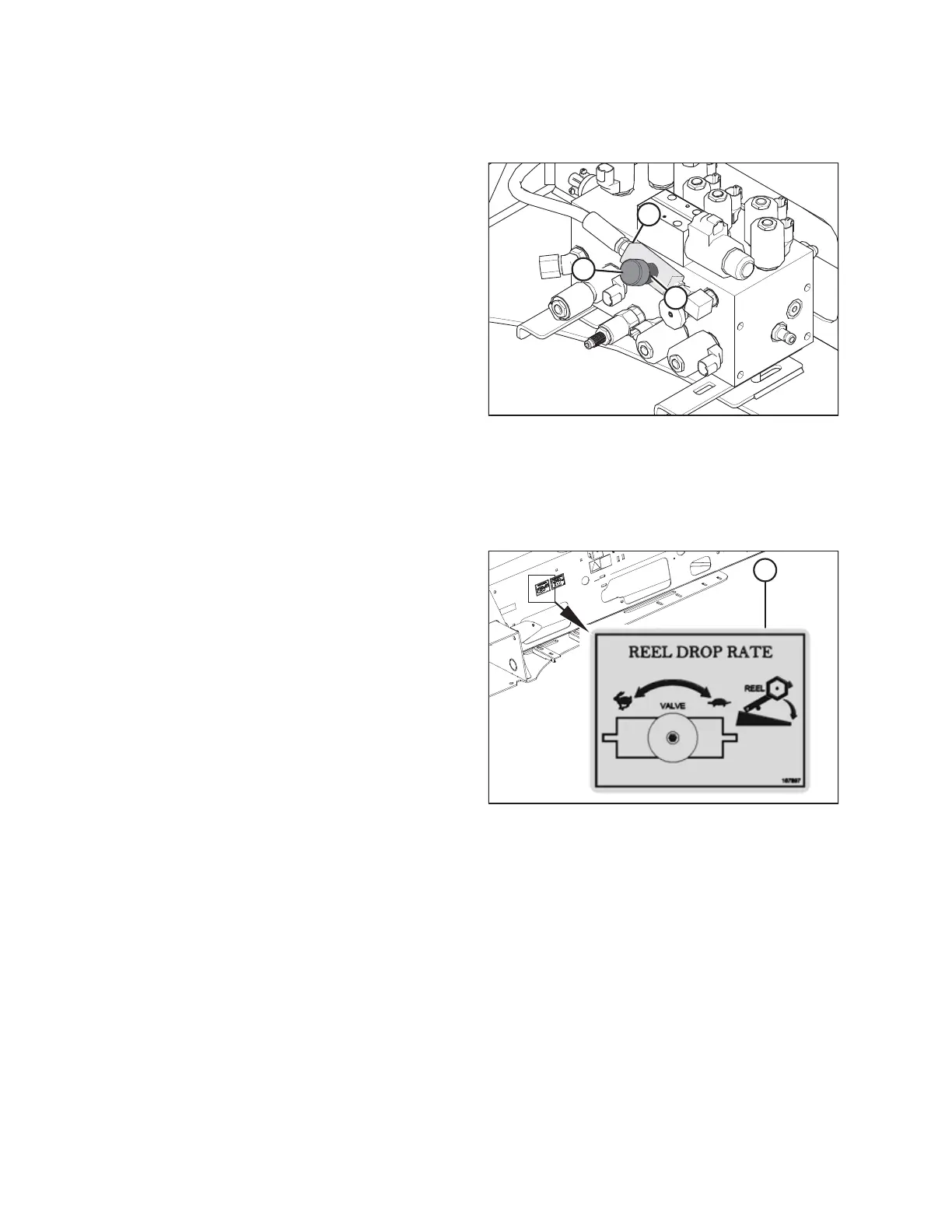

Figure 5.196: Multifunction Control Manifold

4. Locate drop rate control valve (A), installed at port D on the

manifold.

NOTE:

This valve is installed on draper-ready windrowers; it affects

draper headers only.

5. Loosen set screw (B). Turn cap (C) as follows:

• Turn cap (C) clockwise to decrease the reel drop rate.

• Turn cap (C) counterclockwise to increase the reel

drop rate.

6. Check the reel drop rate. Repeat this procedure as needed.

NOTE:

To reset the drop rate to factory specifications, fully close

the needle valve and then open it four turns

counterclockwise.

7. Tighten set screw (B).

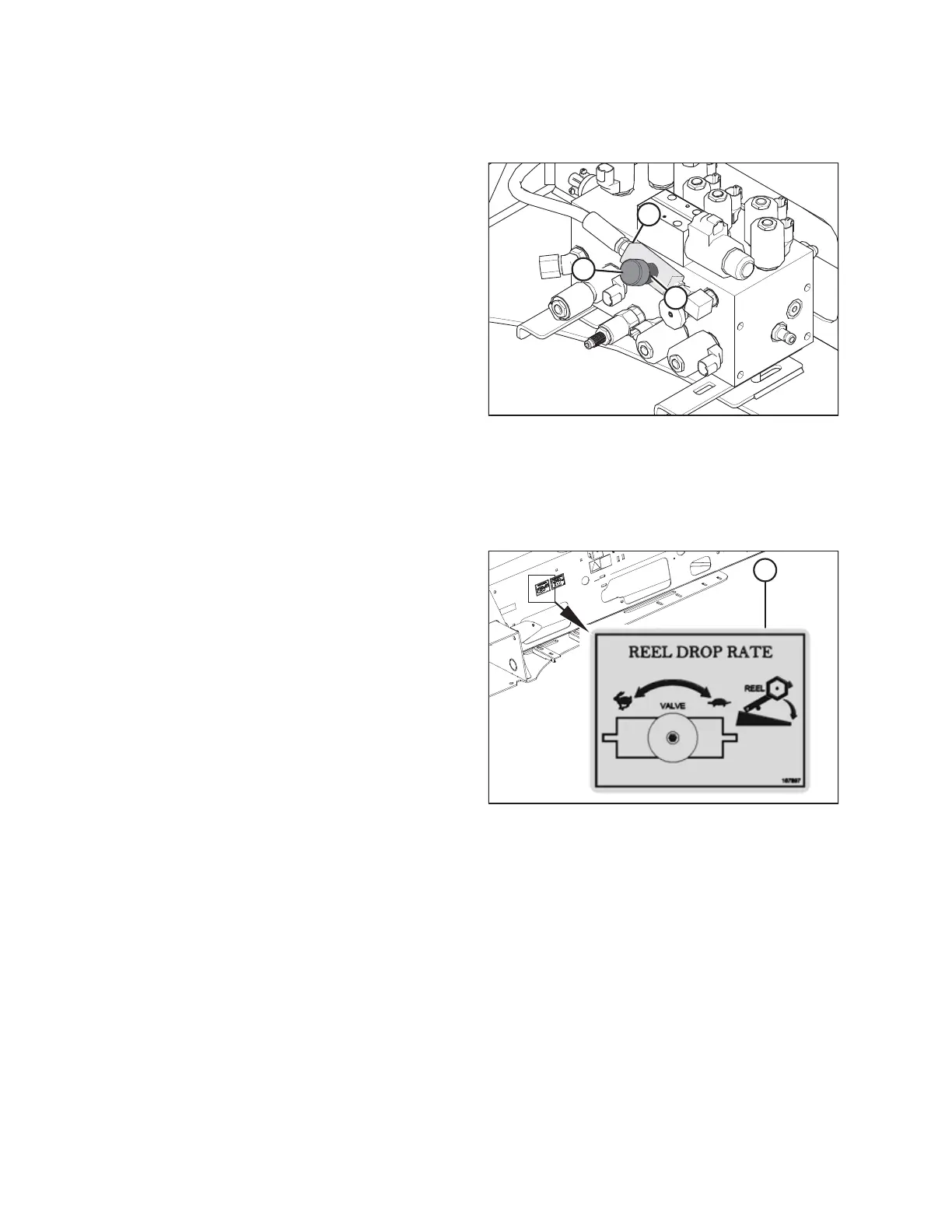

Figure 5.197: Reel Drop Rate Decal

NOTE:

Refer to reel drop rate decal (A) for information on how

changing the valve position affects the reel’s drop rate.

8. Close the platform. For instructions, refer to 5.4.2 Closing

Platforms – Standard Position, page 320.

5.11.6 Traction Drive Hydraulics

The windrower transmission consists of two variable-displacement axial-piston hydraulic pumps; each drive wheel has its

own dedicated pump.

The pumps are driven through a gearbox from the engine. Each pump requires charge flow in order to:

• Compensate for internal hydraulic fluid leakage

• Maintain positive pressure in the main circuit

• Maintain the temperature of the hydraulic system

• Compensate for leakage losses from the external valving or auxiliary systems

The windrower control module (WCM) monitors the charge pressure. The cab display module (CDM) will emit a tone and

display a flashing warning message if the charge pressure drops below 1725 kPa (250 psi). For more information, refer to

Display Warnings and Alarms, page 82.

MAINTENANCE AND SERVICING

Loading...

Loading...