1146

9 PID OPERATION INSTRUCTION

9.2 PID Operation Instruction

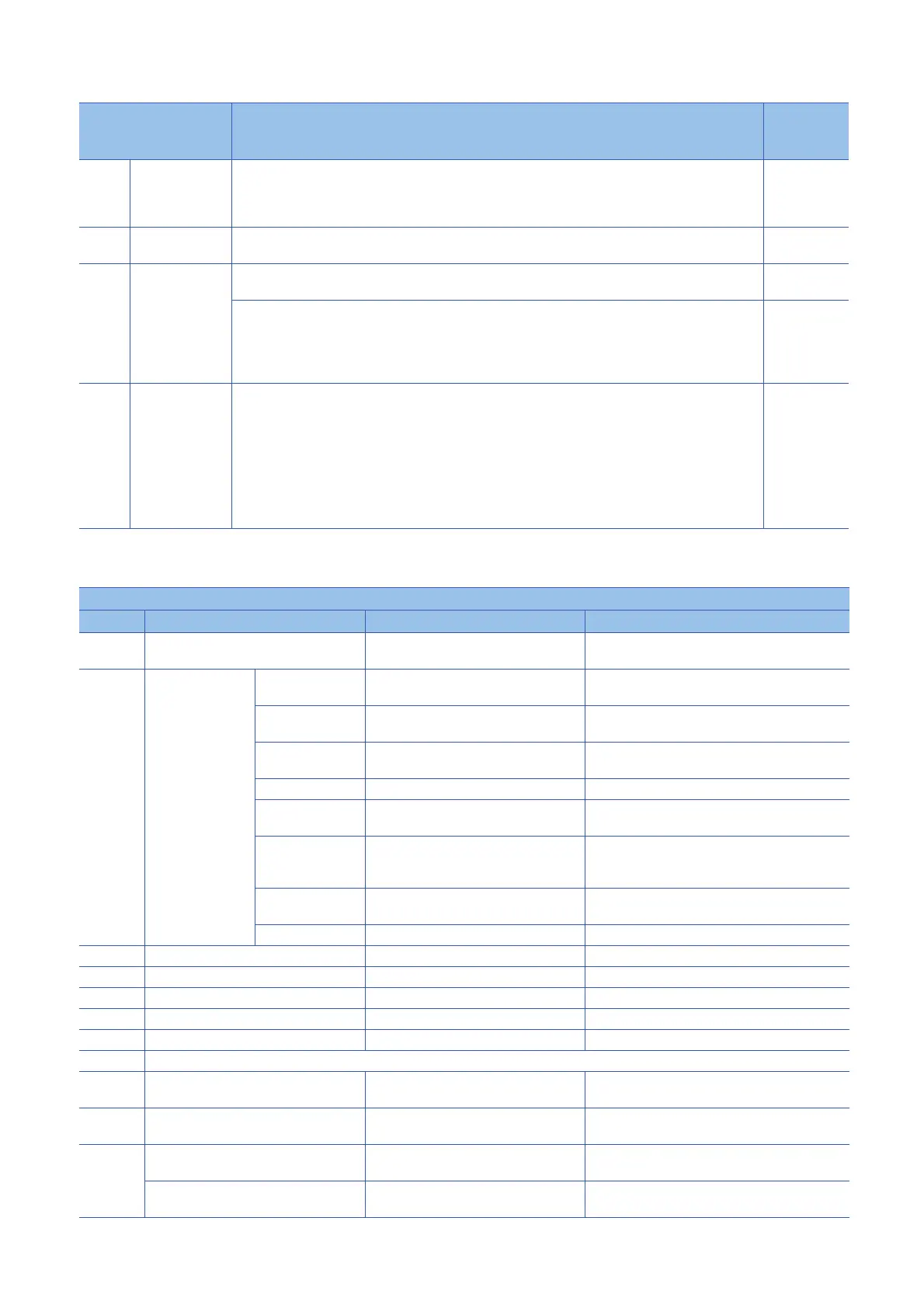

■Setting items (arguments)

*1 When auto tuning is not used, the same number of points are occupied as when the step response method is used.

■Setting items (control data)

Setting item Description Number of

occupied

points

(s1) Set value (SV) Set the set value (SV).

■Auto tuning (limit cycle method)

If the set value for auto tuning differs from that for normal PID control, set a value obtained by adding a bias

value, and then set the SV back to the original value when the auto tuning flag turns off.

1 point

(s2) Process value

(PV)

Set the input value for PID operation. 1 point

(s3) Control data

*1

■Auto tuning (limit cycle method)

The device areas of 29 points starting from the device specified in (s3) are used.

29 points

■Auto tuning (step response method)

The device areas of 25 points starting from the device specified in (s3) are used when all of the bits 1, 2,

and 5 of (s3)+1 (Action setting (ACT)) are not 0.

The device areas of 20 points starting from the device specified in (s3) are occupied when all of the bits 1,

2, and 5 of (s3)+1 (Action setting (ACT)) are 0.

25 points

20 points

(d) Manipulated value

(MV)

■Normal PID control

The user sets the initial manipulated value before execution of the instruction. After execution, the operation

result is stored.

■Auto tuning (limit cycle method)

During auto tuning, the output upper limit value (ULV) or output lower limit value (LLV) is output automatically.

Upon completion of auto tuning, the given MV is set.

■Auto tuning (step response method)

The user sets the step manipulated value before execution of the instruction. During auto tuning, the MV

cannot be changed by the PID instruction.

1 point

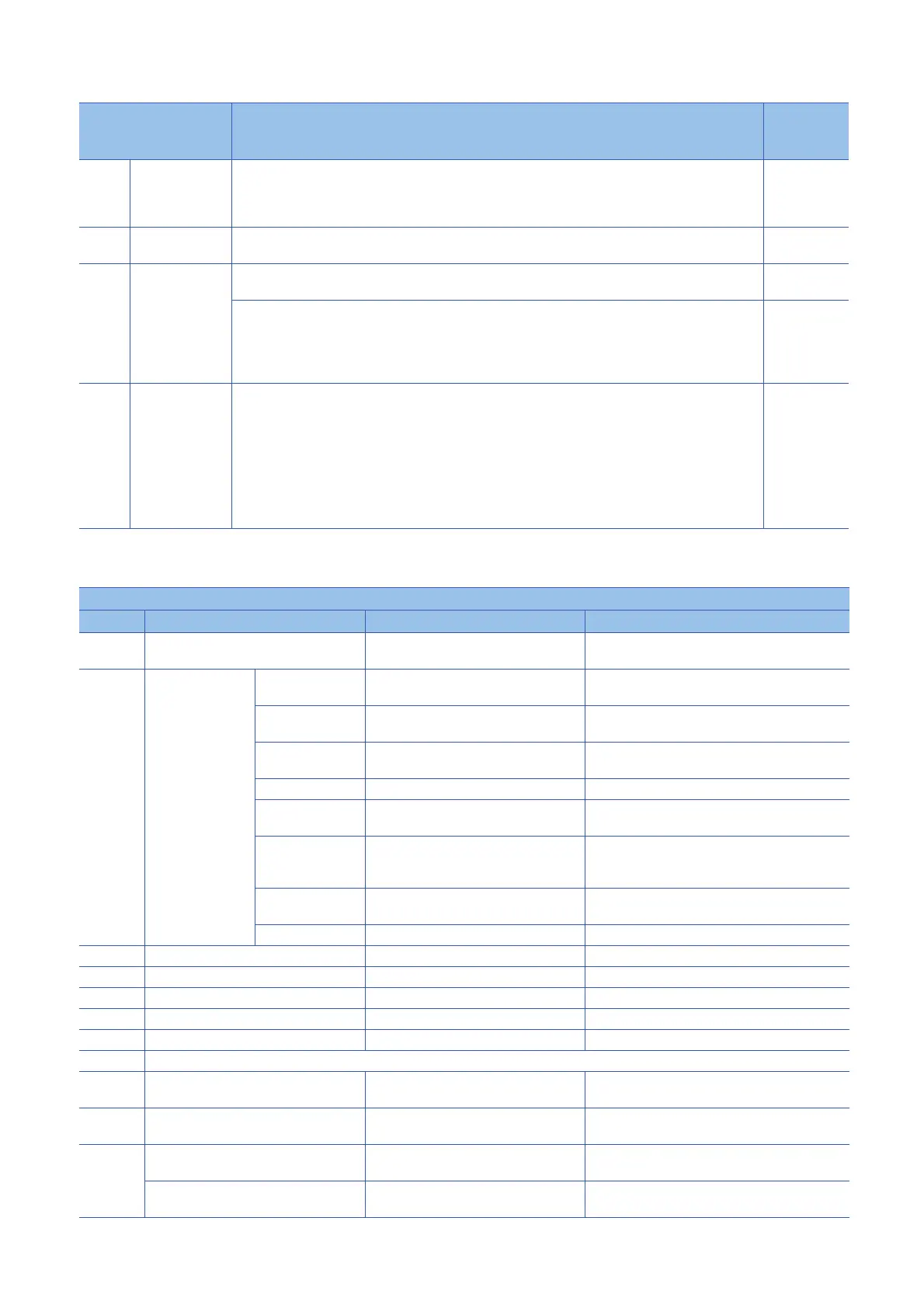

Operand: (s3)

Device Item Description Remarks

+0 Sampling time (T

S

) 1 to 32767 [ms] The sampling time must be longer than the operation

cycle of the programmable controller.

+1 Action setting (ACT) Bit 0 0: Direct action

1: Reverse action

Action direction specification

Bit 1 0: Input variation alarm disabled

1: Input variation alarm enabled

Bit 2 0: Output variation alarm disabled

1: Output variation alarm enabled

Do not turn on bit 2 and bit 5 at the same time.

Bit 3 Reserved

Bit 4 0: Auto tuning disabled

1: Auto tuning enabled

Bit 5 0: No output upper/lower limit value setting

1: Output upper/lower limit value setting

enabled

Do not turn on bit 2 and bit 5 at the same time.

Bit 6 0: Step response method

1: Limit cycle method

Auto tuning mode selection

Bits 7 to 15 Reserved

+2 Input filter constant () 0 to 99 [%] 0 = No input filter

+3 Proportional gain (K

P

) 1 to 32767 [%]

+4 Integral time (T

I

) 1 to 32767 [ 100ms] 0 = (No integration)

+5 Derivative gain (K

D

) 0 to 200 [%] 0 = No derivative gain

+6 Derivative time (T

D

) 1 to 32767 [ 10ms] 0 = No derivation

+7 to +19 These areas are used for internal processing of PID operation, and therefore data cannot be changed.

+20

*1

Input variation (increase) alarm setting

value

0 to 32767 Enabled when the bit 1 of (s3)+1 (Action direction

(ACT)) is 1.

+21

*1

Input variation (decrease) alarm setting

value

0 to 32767 Enabled when the bit 1 of (s3)+1 (Action direction

(ACT)) is 1.

+22

*1

Output variation (increase) alarm setting

value

0 to 32767 Enabled when the bit 2 of (s3)+1 (Action direction

(ACT)) is 1, and the bit 5 is 0.

Output upper limit setting value -32768 to 32767 Enabled when the bit 2 of (s3)+1 (Action direction

(ACT)) is 0, and the bit 5 is 1.

Loading...

Loading...