407

When print data is received without returning to the original position with <IK>1,120, printing will start

from the current stop position.

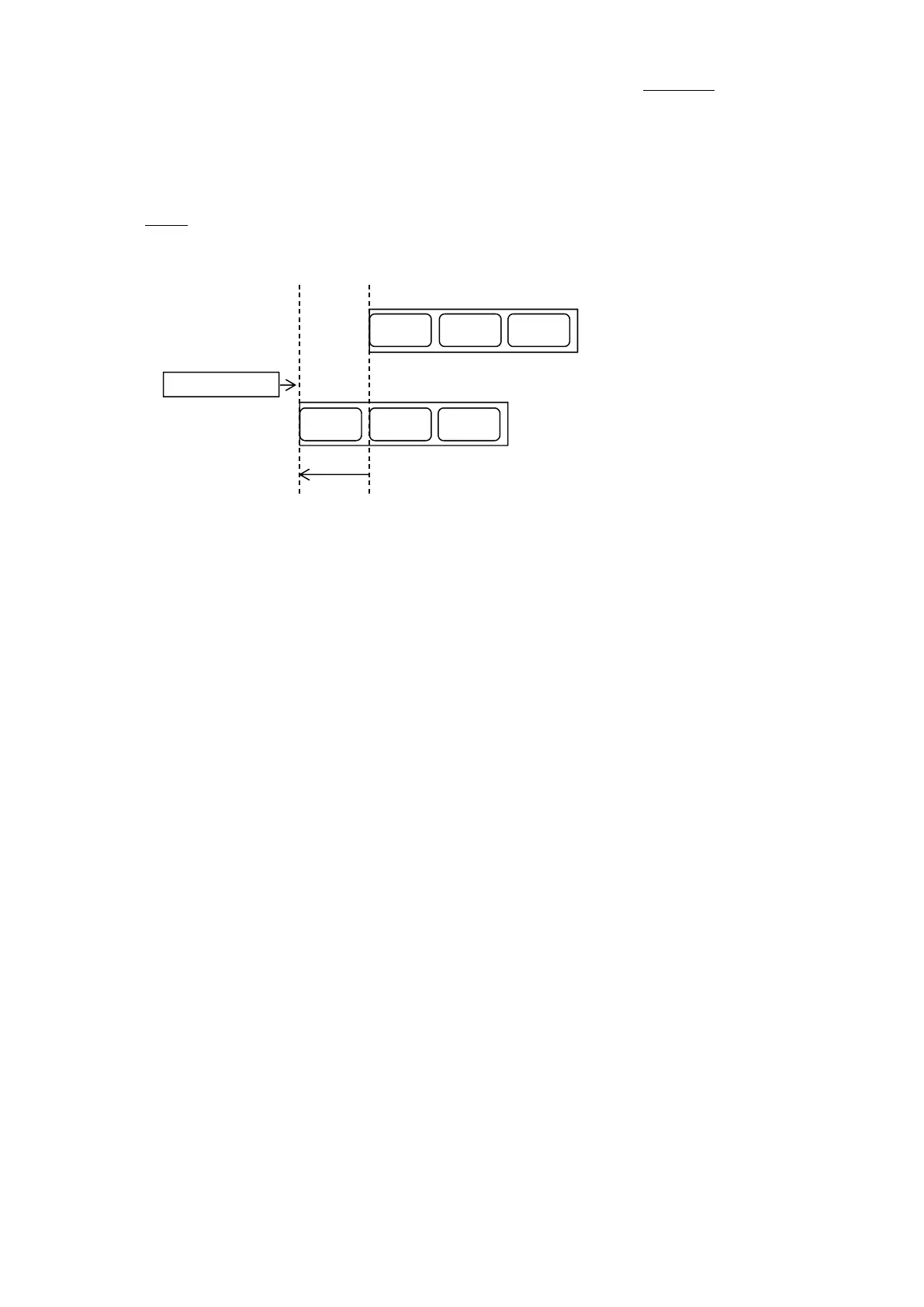

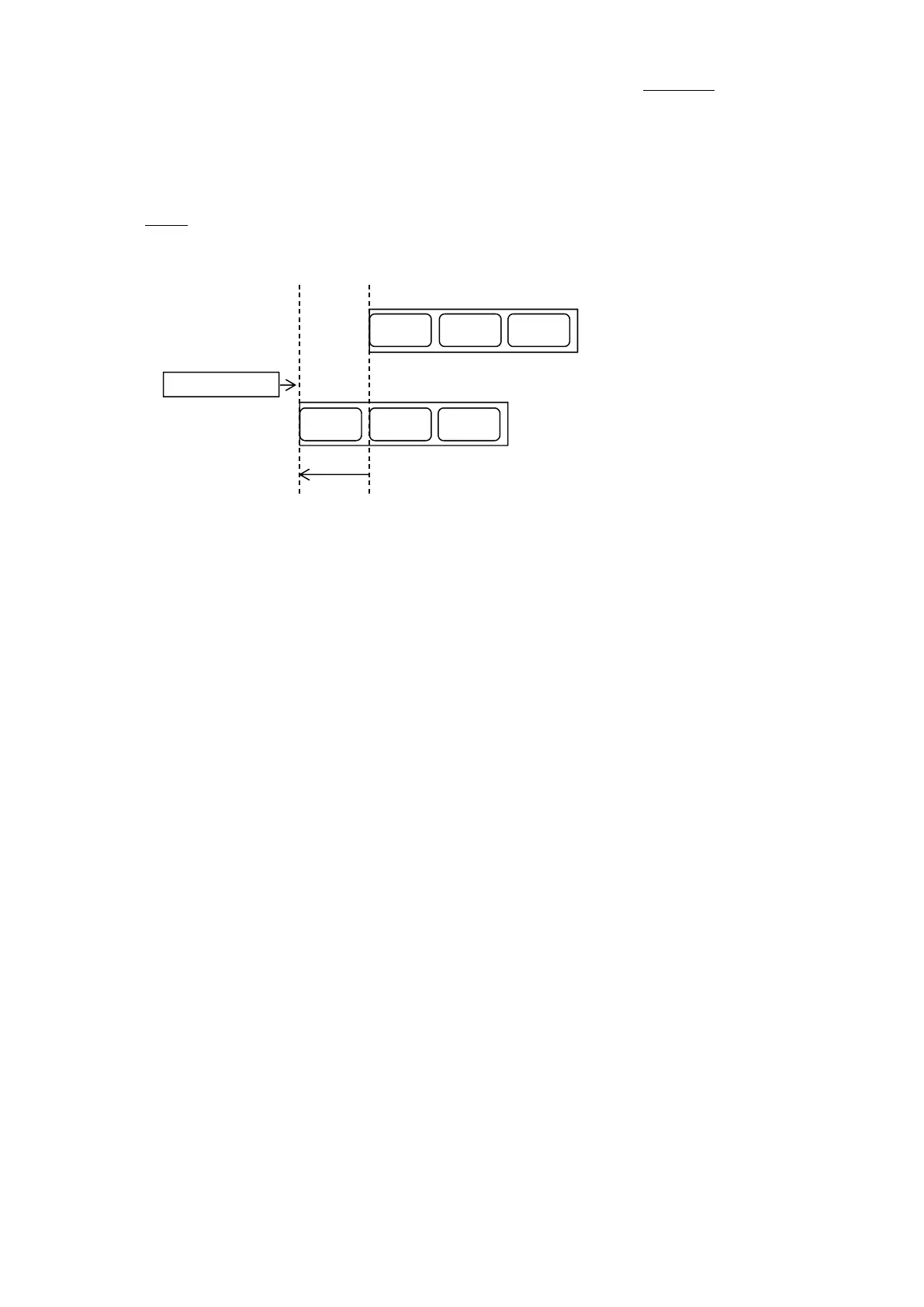

[Coding Example2]

When feeding one label

<A>

<IK>0

<Z>

1

Before receiving command

Command received

Feeds one label

After receiving command

2

3

1

2

3

Head position

[Supplementary Explanation]

• Delimit Start of Data Transmission <A> and End of Data Transmission <Z> with this command.

When specifying this command with the same item as print data, the command will be ignored.

• When setting [Label feed direction] to [1: Backfeed], length of label feed needs to be checked. If

this length is very long, it may cause overlapped prints or label may fall off the platen and result

in detection error as paper-end.

• When setting [Thermal transfer] to [Print method], length of label backfeed needs to be under

30mm.

Failure to do so may result in detection error as ribbon end. And also, avoid consecutive

specification of label feed command for backfeed.

• In cutter and dispenser mode, do not attempt to backfeed right after cutting and dispensing

label.

• When omitting [No. of label feed] in forward feed, printer motion will be similar to label feed

motion when pressing the FEED key in offline state.

• Label feed motion with this command will be activated at the time of online.

• Control of feed motion by external signal is not available.

• When omitting [No. of label feed] in backfeed, label feed will not be performed due to command

error.

• When the sensor is disabled in continuous mode, <IK>0 (omission of [No. of label feed]) will not

feed labels.

• When the specified feed value is outside of valid range, printing will not be performed due to

command error.

• The valid feeding range in the backward direction is from 6 mm to 60 mm. The command error

occurs when the feeding length is out of range and the media is not fed.

• Actual feed distance may be different from the set value according to the individual difference of

each printer, supplies and operating environment. Recommend to adjust the feed value before

operation.

Loading...

Loading...