Section 04 ENGINE (2-STROKE)

Subsection 05 (BOTTOM END)

NOTE: Crankshaft deflection cannot be correctly

measured between centers of a lathe.

Connecting Rod Big End Axial Play

CONNECTING ROD BIG END AXIAL PLAY

MODEL

NEW PARTS

(min.) (max.)

WEAR

LIMIT

717

engines

0.311 mm

(.012 in)

0.677 mm

(.026 in)

1.2 mm

(.047 in)

787 RFI

engines

0.230 mm

(.008 in)

0.617 mm

(.024 in)

1.2 mm

(.047 in)

947 DI

engines

0.390 mm

(.015 in)

0.737 mm

(.029 in)

1.2 mm

(.047 in)

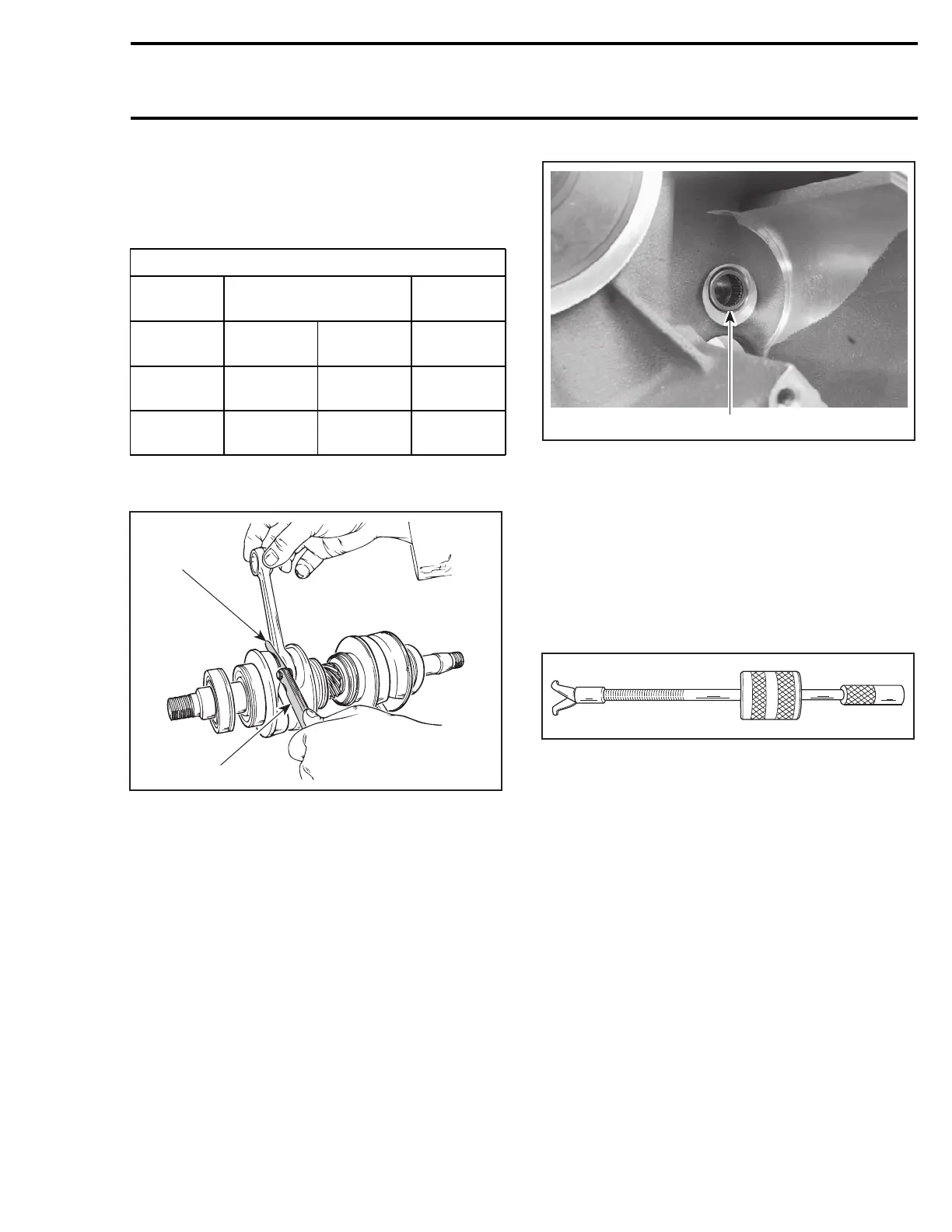

Using a feeler gauge, measure distance between

thrust washer and crankshaft counterweight.

F01D1WA

1

2

1. Measuring big end axial play

2. Feeler gauge

Starter Drive Bearing

947 DI Engines Only

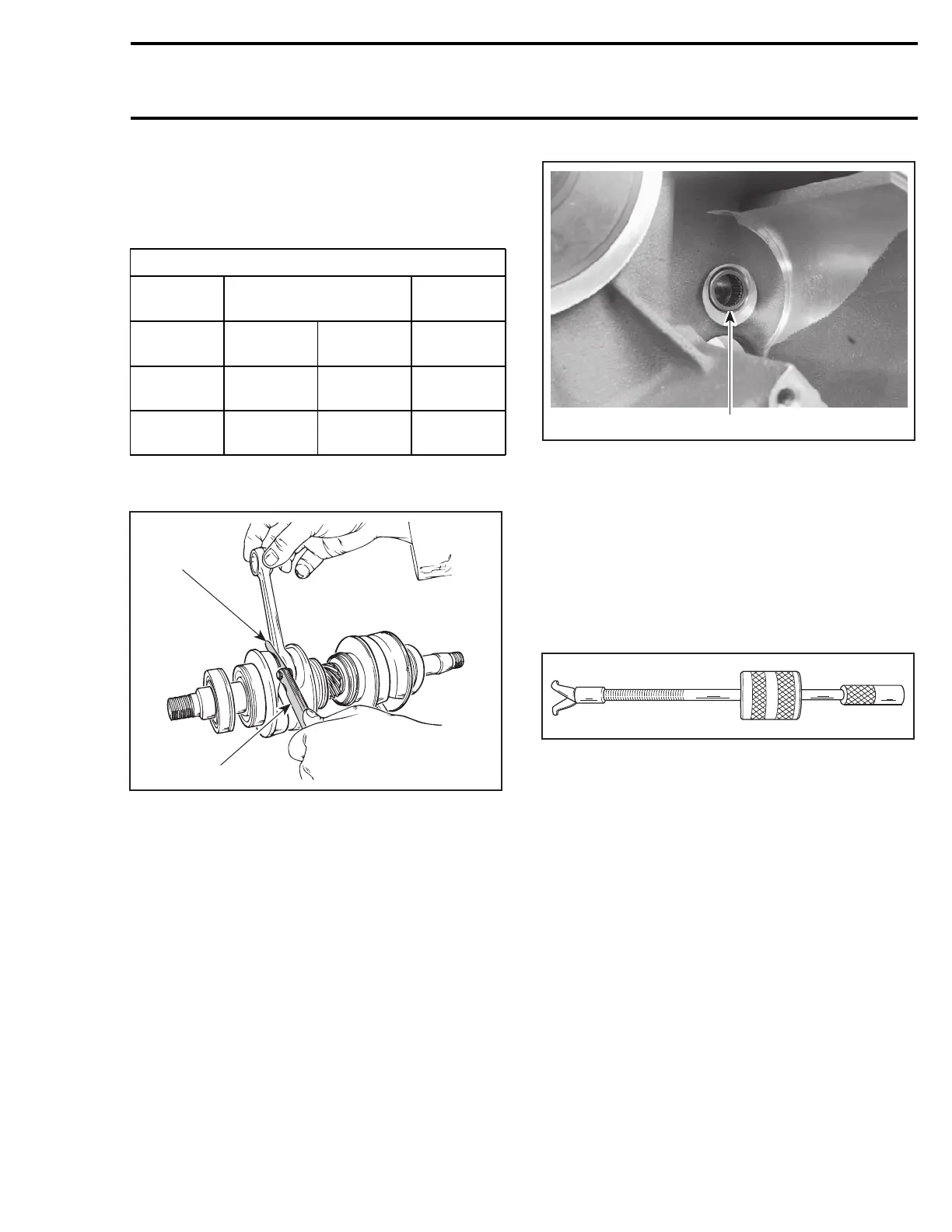

Check bearing no. 23 of starter drive assembly

no. 27 in crankcase.

F06D1IA

1

1. Bearing of starter drive assembly

Removal

Starter drive bearing can be easily removed from

lower crankcase half using the following suggest-

ed tool or equivalent:

– Snap-onhammerpullerincluding:

– handle CJ93-1

– hammer CJ125-6

– claws CJ93-4.

F01J0ZA

Closepullerclawssothattheycanbeinsertedin

end bearing. Holding claws, turn puller shaft clock

wise so that claws open and become firmly tight

against bearing.

Slide puller hammer outwards and tap puller end.

Retighten claws as necessary to always maintain

them tight against bearing. Continue this way un-

til bearing completely comes out.

For installation, see below in this section.

Reed Valve

947 DI Engines Only

Check reed valve petals no. 29 for cracks or other

defects. The reed petals must lie completely flat

against the reed valve body no. 30. To check, hold

against light.

smr2004-Complete Line Up 143

Loading...

Loading...