Section 04 ENGINE (2-STROKE)

Subsection 05 (BOTTOM END)

947 DI Engines

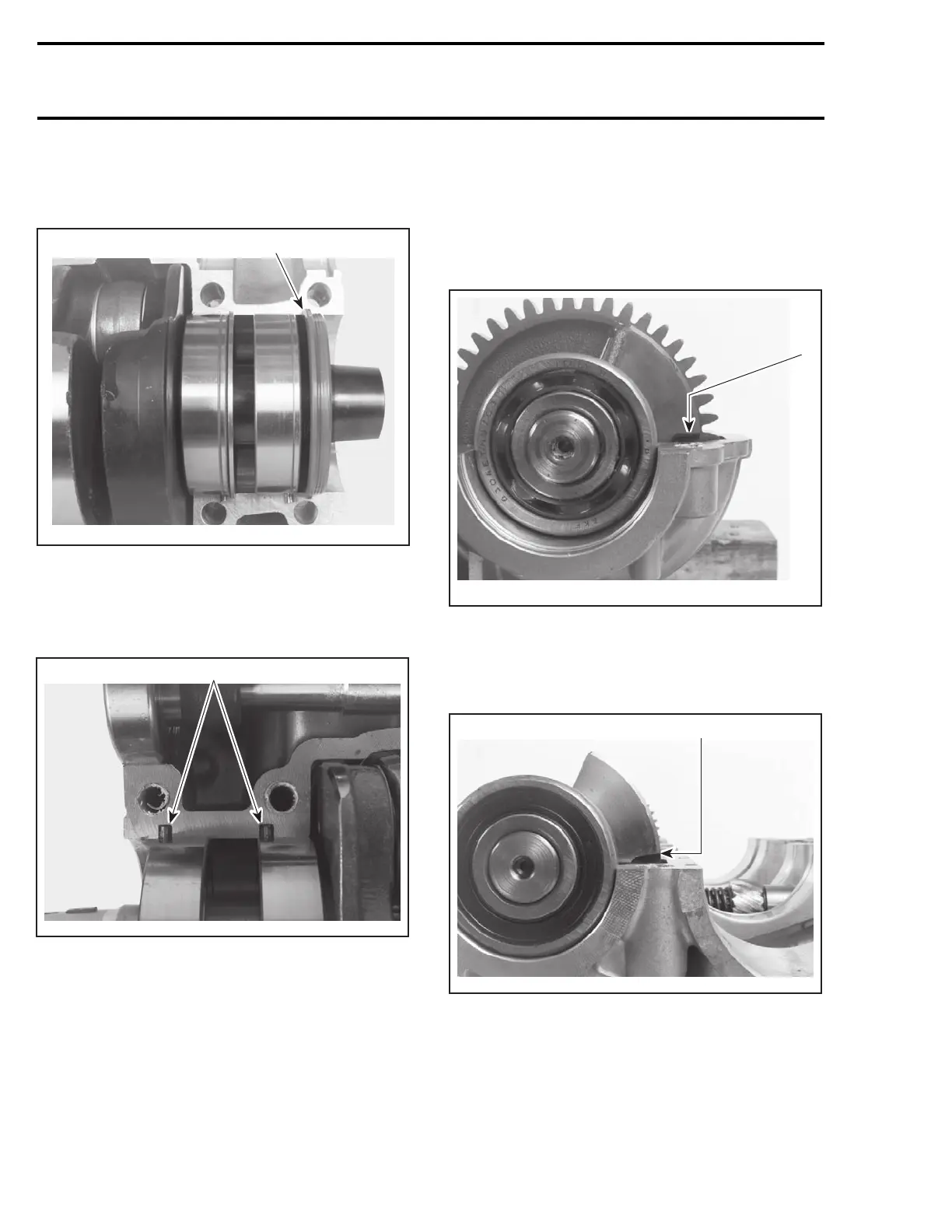

Seals are positioned with the outer lip in the

crankcase recess.

F06D1LA

1

1. Seallipincrankcaserecess

Drive Pin

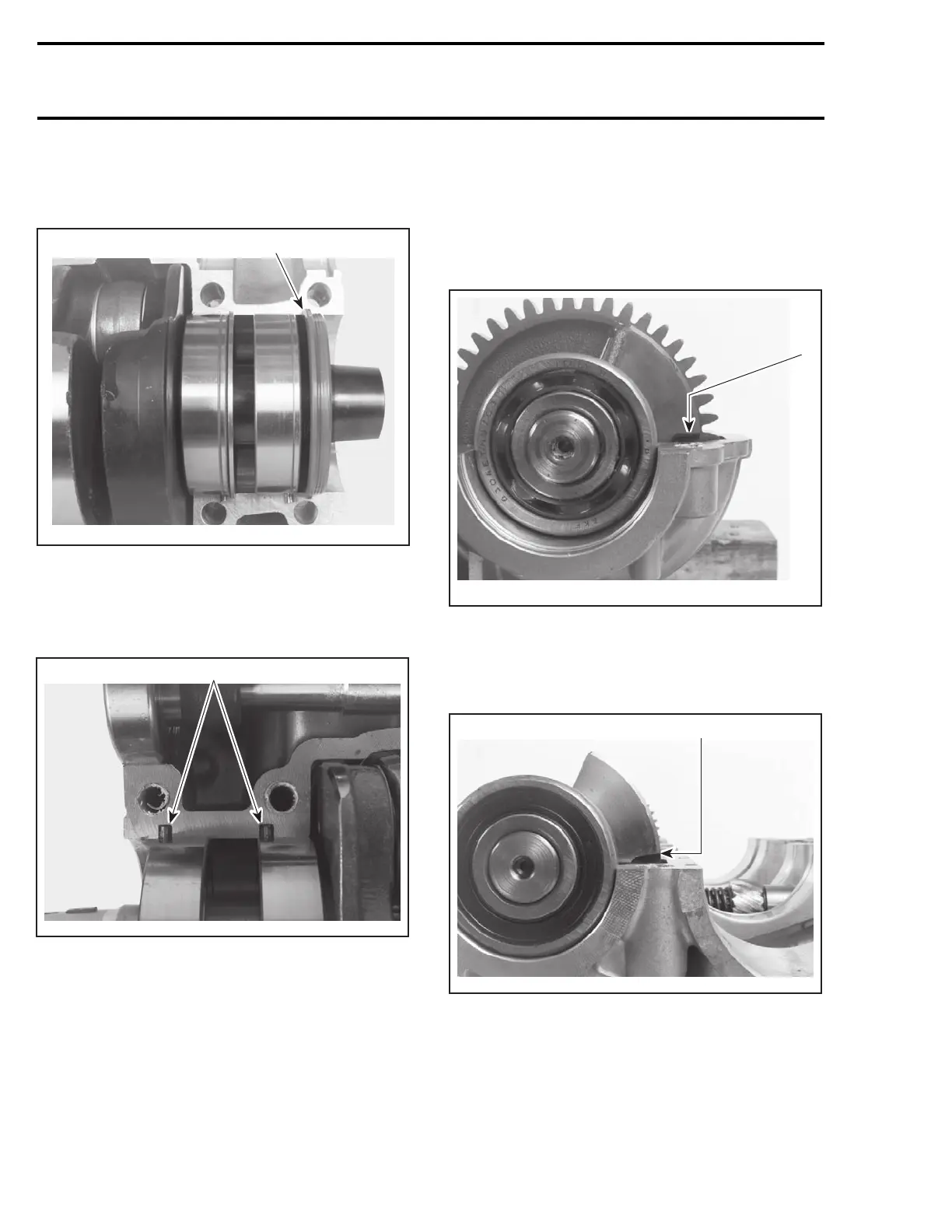

Make sure drive pins no. 6 of bearings are properly

installed in crankcase recesses at assembly.

F00D0OA

1

1. Drive pins

Counterbalance Shaft

787 RFI Engines

Press gear no. 14 onto counterbalance shaft

no. 13 taking care to align both marks previously

traced.

CAUTION: Counterbalance shaft must be prop-

erly assembled, otherwise engine will vibrate

and premature wear will occur.

Proceed as follows to check if the gear no. 14 is

properly positioned on the counterbalance shaft:

– Temporarily install the counterbalance shaft in

the crankcase.

– Rotate the counterbalance shaft to align the

notch of the gear with the crankcase.

F00D0UA

1

1. Gear notch aligned with the crankcase

– The notch of the couterweight on the opposite

end of the counterbalance shaft must also be

aligned with the cranckcase.

F00D0VA

1

1. Counterweight notch aligned with the crankcase

If notches are not aligned with the crankcase, re-

move the gear and repeat the procedure until the

notches are properly aligned.

947 DI Engines

Install bearing no. 31 and washer no. 32.

146 smr2004-Complete Line Up

Loading...

Loading...