Section 05 ENGINE (4-TEC)

Subsection 04 (REMOVAL AND INSTALLATION)

To verify alignment proceed as follows:

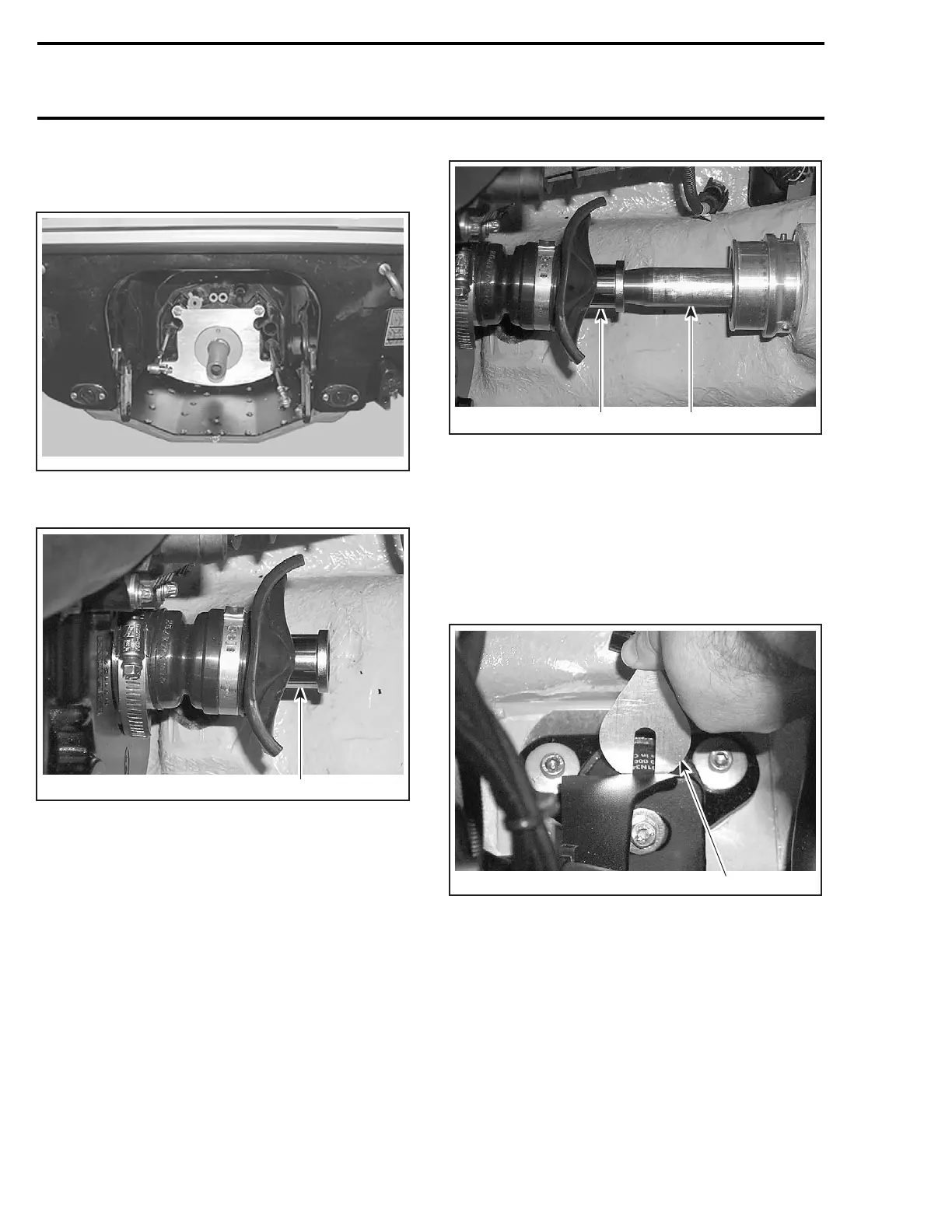

– Secure plate and support to hull with four nuts.

F19D0AA

– Install adapter (P/N 529 035 719 ) in engine PTO

housing.

1

F18D18A

1. Engine alignment adapter

– Carefully slide shaft through support.

– Insert shaft end into engine alignment adapter.

NOTE: Ensure the protective hose and carbon ring

(or seal carrier) is removed to check engine align-

ment. If the alignment is correct, the shaft will

slide easily without any deflection in engine al

ign-

ment adapter.

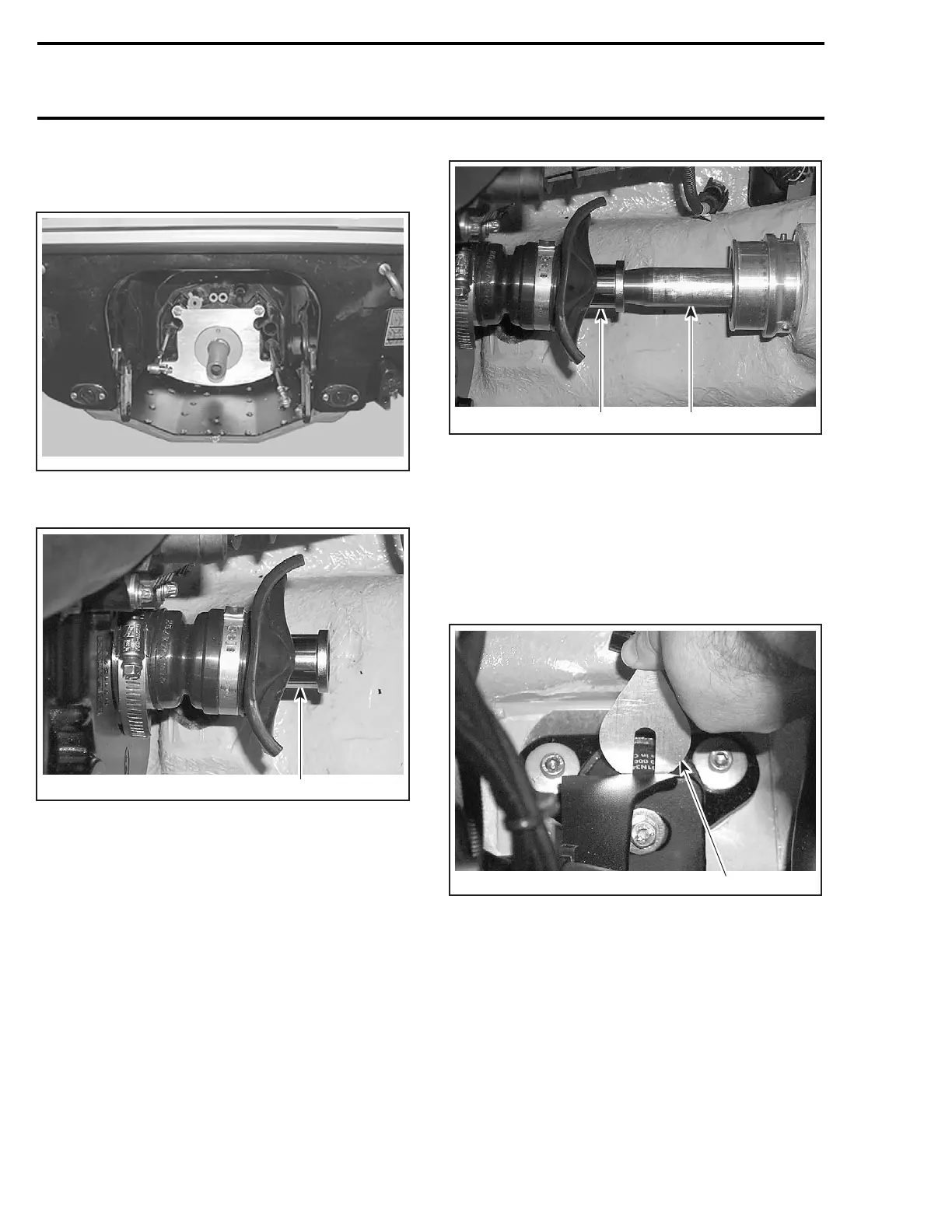

1

F18D17A

2

TYPICAL

1. Engine alignment adapter

2. Alignment shaft

If the alignment is incorrect loosen engine sup-

port screws to enable to align engine alignment

adapter with shaft end.

NOTE: Use shim(s) (P/N 270 000 024) or (P/N 270

000 025) as necessary between engine supports

and rubber mounts to correct alignment.

1

F18D15A

TYPICAL

1. Shim

CAUTION: Whenever shims are used to cor-

rect alignment, never install more than 5 mm

(0.196 in) shim thickness.

Engine Support Screws

Apply Loctite 243 (blue) (P/N 293 800 060) on

screw threads.

Torque engine support screws to 25 N•m

(18 lbf•ft) when procedure is completed.

222 smr2004-Complete Line Up

Loading...

Loading...