Section10FUELSYSTEM

Subsection 03 (CARBURETOR)

Replace filter if damaged.

F01F0YA

1

TYPICAL

1. Filter

Fuel Accelerator Pump

Disconnect inlet and outlet hoses from accelerator

pump nipples.

F06F06A

1 2

TYPICAL

1. Fuel inlet hose

2. Fuel outlet hose

Using a suitable pump gauge tester, perform the

following test proceeding as follows:

– Install pump gauge tester (P/N 295 000 114) on

inlet nipple of accelerator pump .

– Obstruct outlet nipple with a finger and hold

while pumping.

– Pump tester until it reaches 28 kPa (4 PSI).

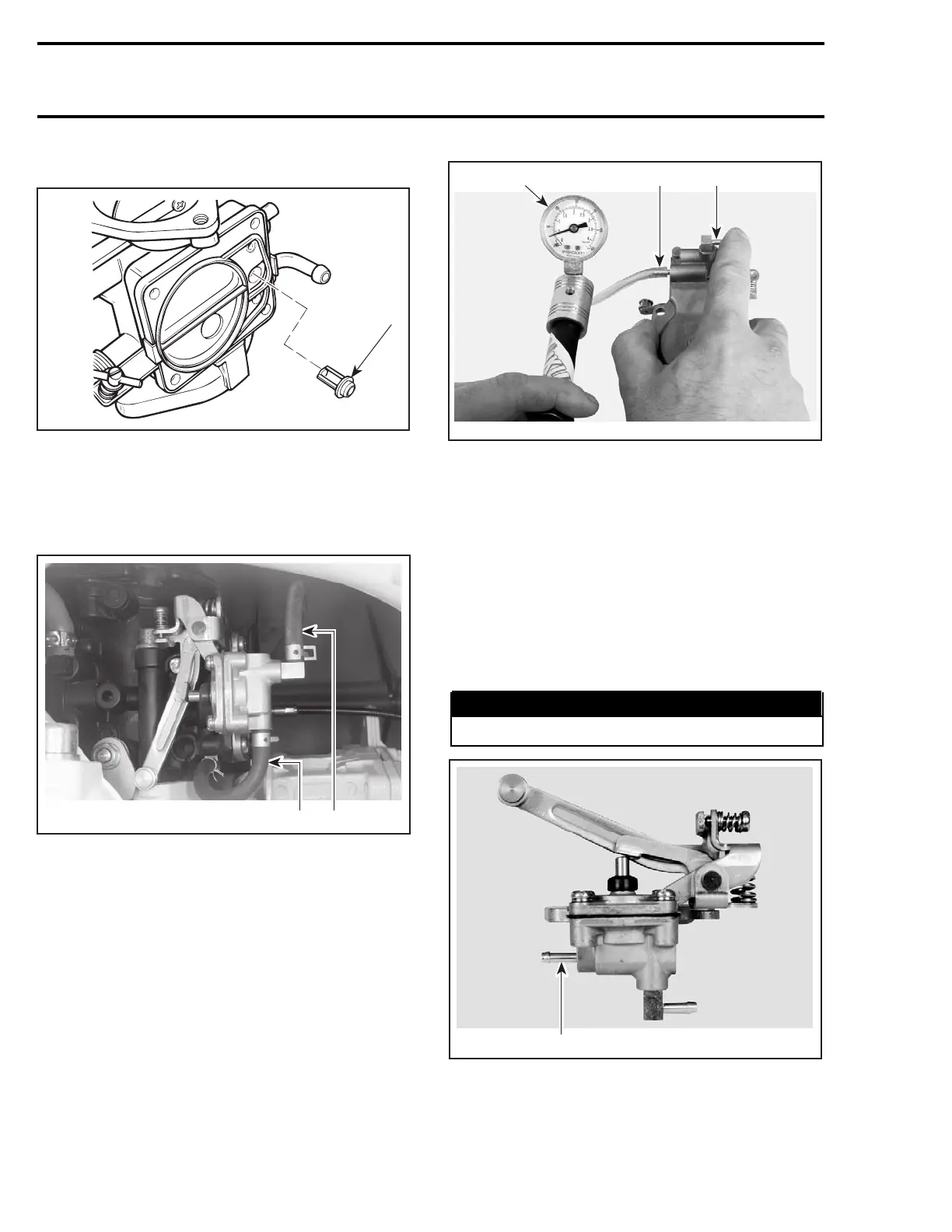

F06F07A

213

1. Pump gauge tester

2. Hose installed to inlet nipple

3. Outlet nipple obstructed

Diaphragm no. 10 must stand pressure for 10 sec-

onds. If pressure drops, replace accelerator pump

diaphragm.

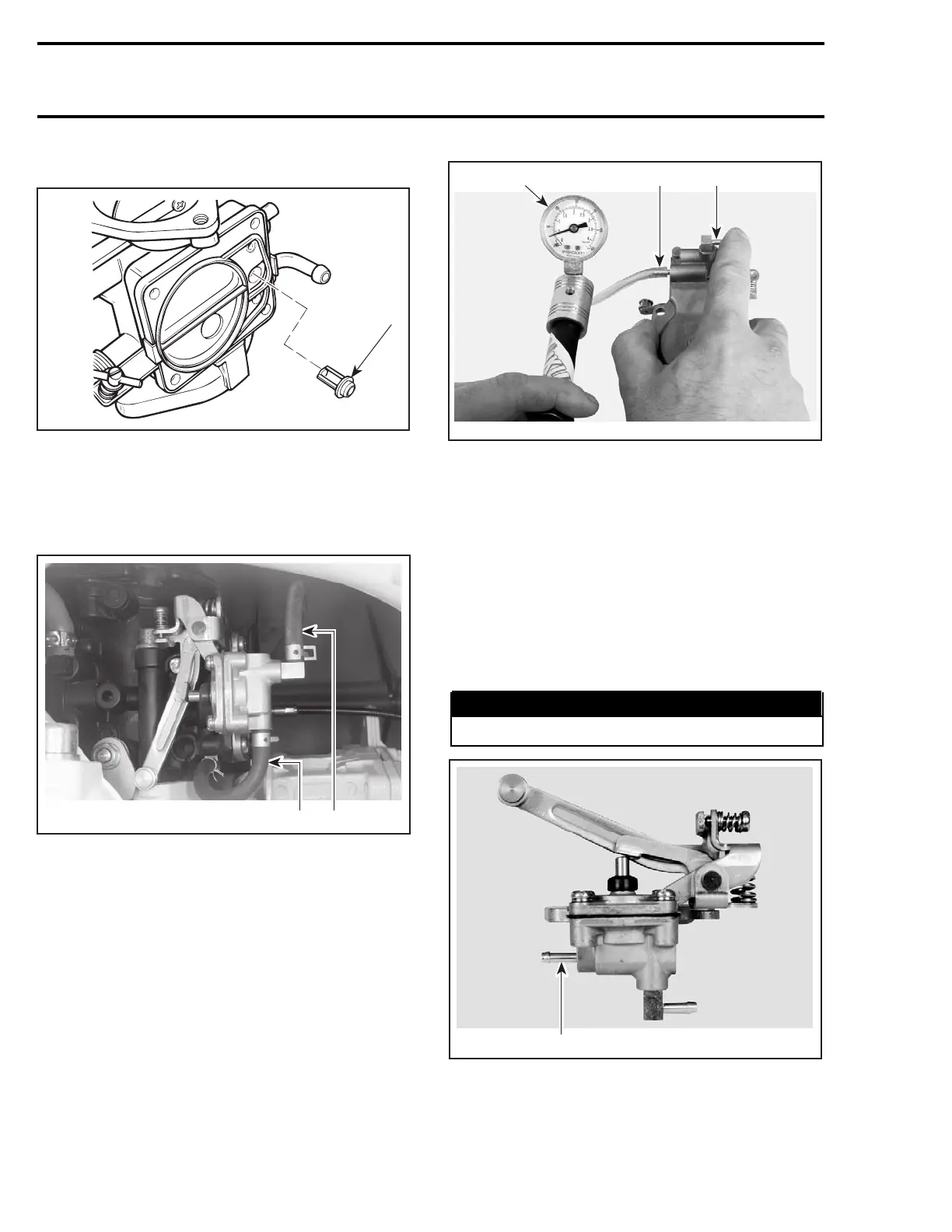

Verify accelerator pump check valves operation as

follows:

Connect a clean plastic tubing to the valve inlet

nipple and alternately apply pressure and vacuum.

The check valve should release with pressure and

hold under vacuum.

WARNING

Some fuel may be present in fuel pump.

F06F08A

1

TYPICAL

1. Apply pressure and vacuum at inlet nipple

To check the injector, install pump gauge tester to

the injector hose.

522 smr2004-Complete Line Up

Loading...

Loading...