Section12ELECTRICALSYSTEM

Subsection 03 (STARTING SYSTEM)

WARNING

Always connect RED positive cable first then

BLACK negative cable last. Whenever con-

necting the RED positive cable to the starter

motor make sure the battery cables are dis-

connected to prevent electric shock.

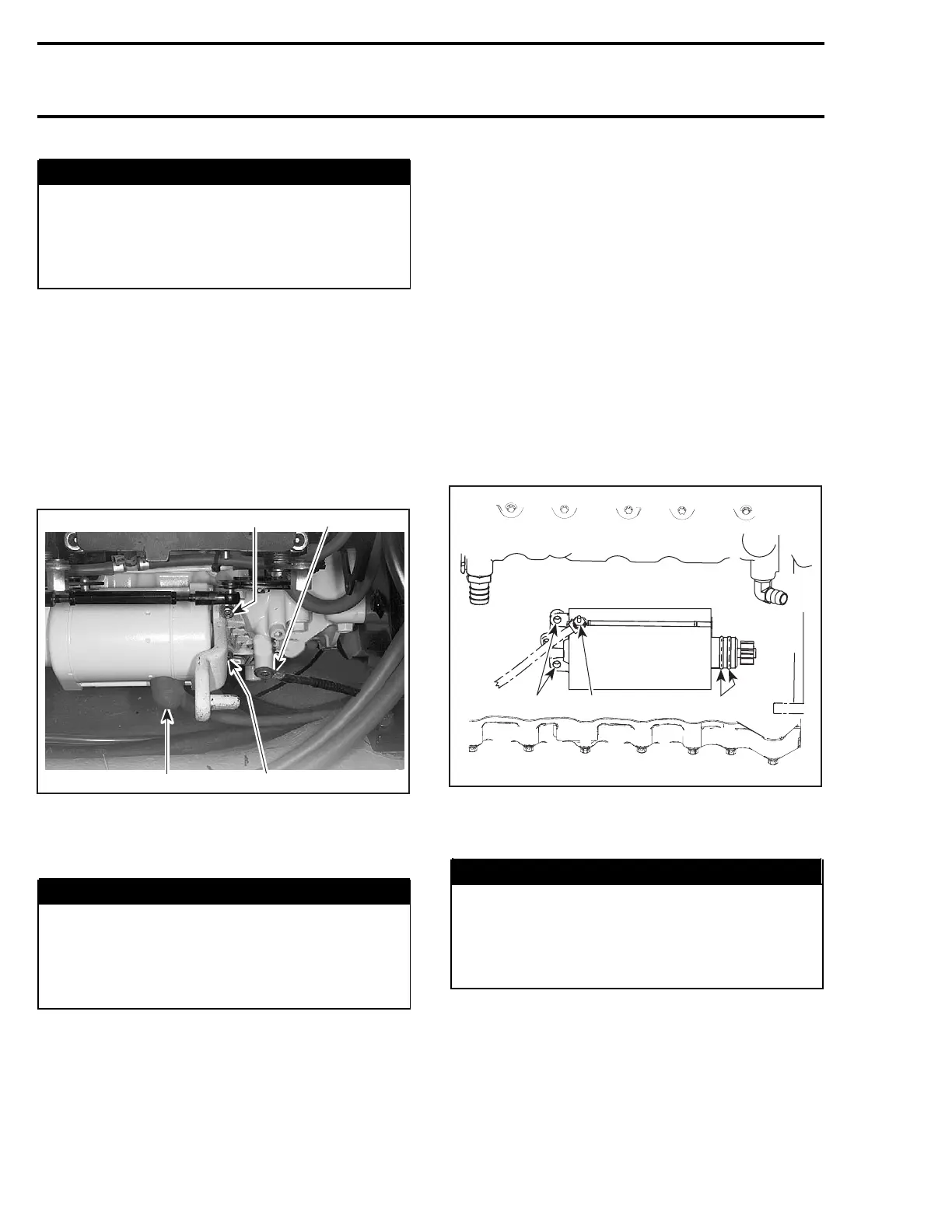

947 DI Engines

Screw

Apply Loctite 243 (blue) to Allen screws no. 16 of

starter bracket and torque to 10 N•m(89lbf•in).

Nut

Connect the RED positive cable to the starter and

torque nut no. 17 to 6 N•m(53lbf•in). Apply

dielectric grease on terminal and nut.

F06H35B

2

1

3

3

947 DI ENGINES

1. Torque nut to 6 N•m(53lbf•in), apply dielectric grease

and install protection cover

2. Negative BLACK cable

3. 10 N•m(89lbf•

in)

WARNING

Always connect RED positive cable first then

BLACK negative cable last. Whenever con-

necting the RED positive cable to the starter

motor make sure the battery cables are dis-

connected to prevent electric shock.

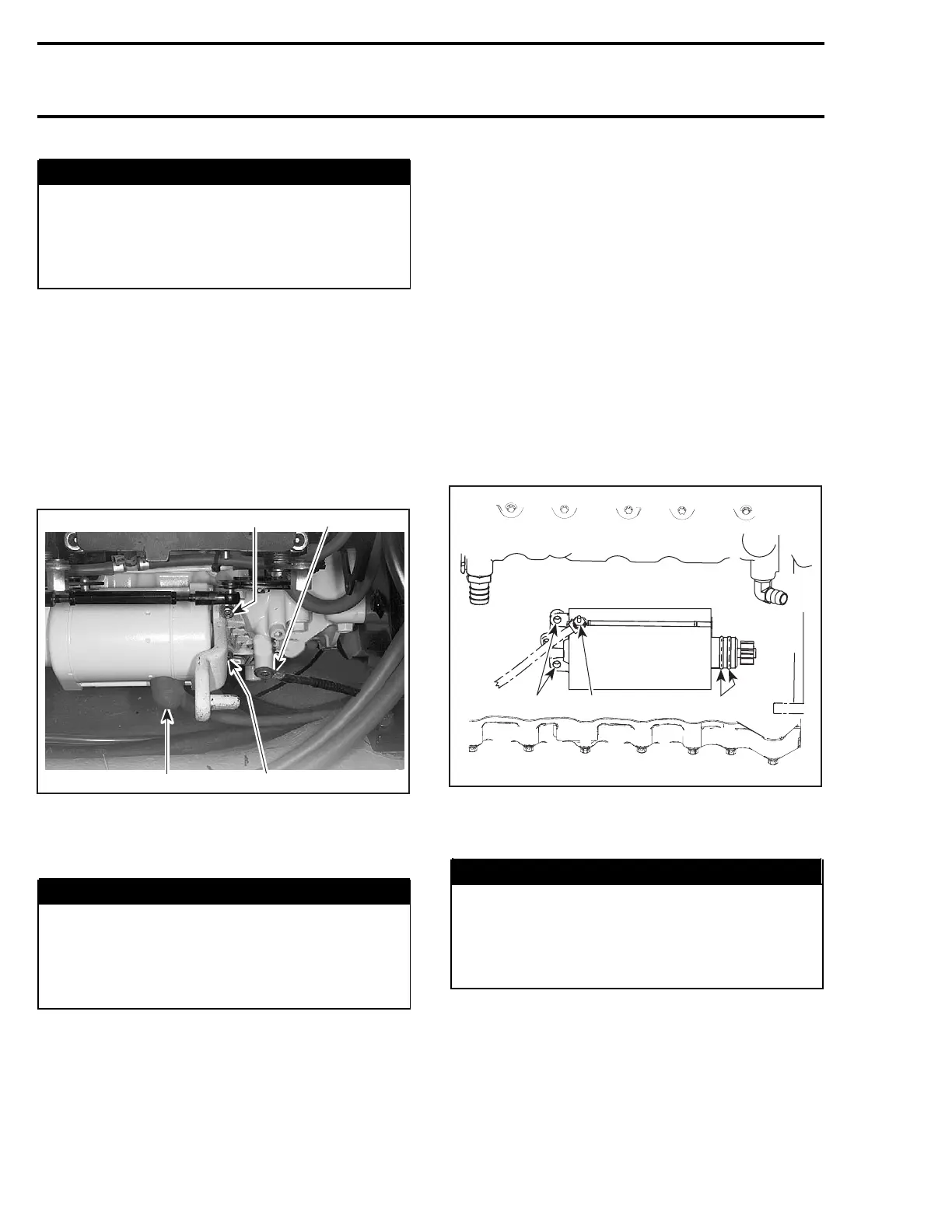

4-TEC Engines

Apply grease Isoflex Topas NB52 (P/N 293 550

021) on O-rings of starter.

Install starter.

NOTE: If starter does not mesh properly, try to pull

it out and slightly rotate the starter gear; then re-

install starter. One could also temporarily remove

both O-rings, properly mesh gears then remove

starter to reinstall O-rings, being careful not to ro-

tate gear to keep its position, to finally reinstall

starter.

Apply Loctite 243 (blue) on retaining screws no. 1

and torque to10 N•m(89lbf•in).

Nut

Connect the RED positive cable to the starter and

torque nut to 7 N•m(62lbf•in). Apply dielectric

grease on terminal and nut.

Ensure to slide protector over nut to hide metallic

parts.

3

2

1

F18H0UB

1. Grease on O-rings.

2. Torque nut to 7 N•m(62lbf•

in) and apply dielectric

grease and install protection cover

3. 10 N•m(89lbf•

in)

WARNING

Always connect RED positive cable first then

BLACK negative cable last. Whenever con-

necting the RED positive cable to the starter

motor make sure the battery cables are dis-

connected to prevent electric shock.

588 smr2004-Complete Line Up

Loading...

Loading...