Section13PROPULSION

Subsection 01 (JET PUMP)

F01J0DA

1

TYPICAL

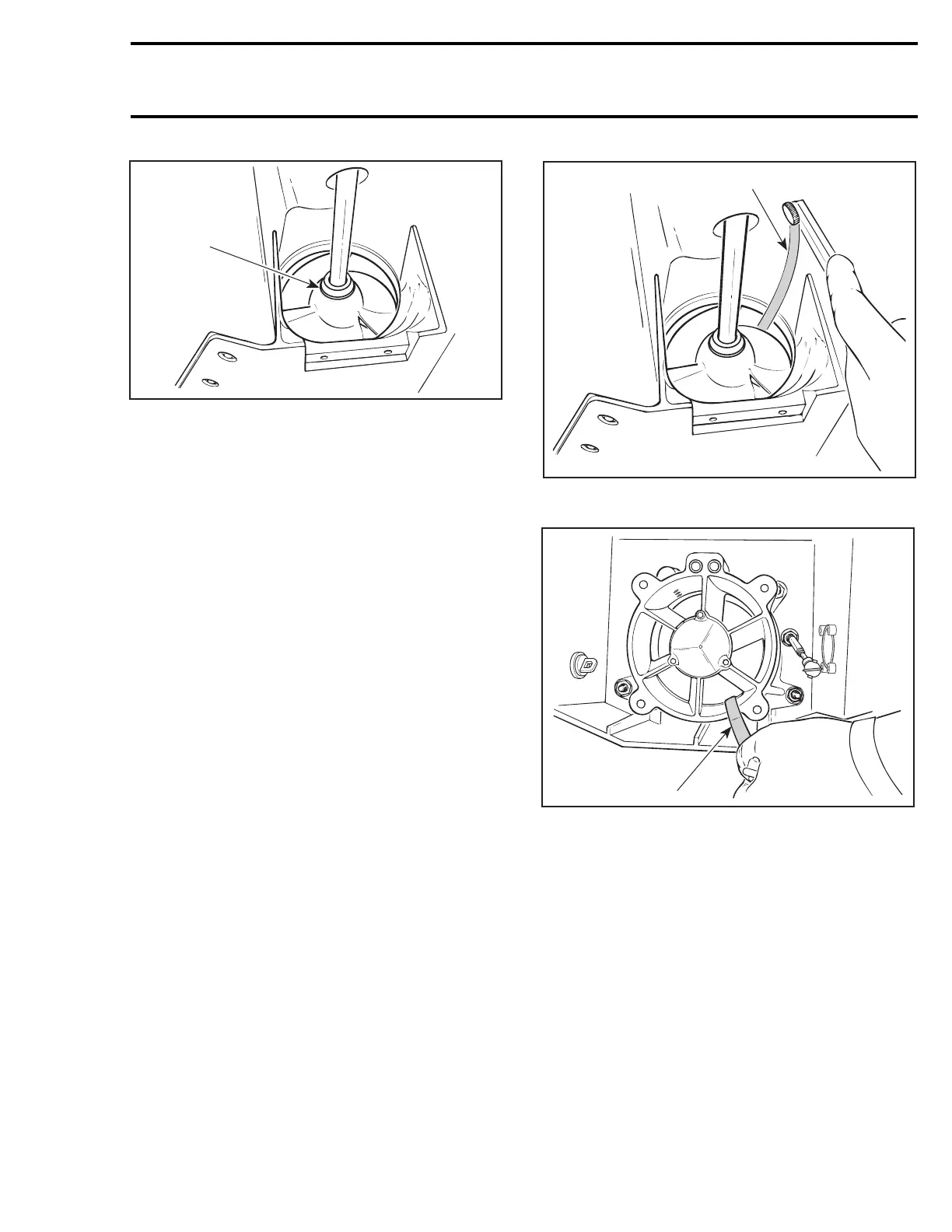

1. Inspect impeller and boot

Impeller/Wear Ring Clearance

This clearance is critical for jet pump performance.

Clearance can be checked from water inlet open-

ing or from venturi side. However, the last

method requires more work.

To check clearance from water inlet side, remove

inlet grate.

To check clearance from venturi side, remove ven-

turi/nozzle assembly as described in OIL INSPEC-

TION in this subsection.

Using a feeler gauge with 30 cm (12 in) blades,

measure clearance between impeller blade tip

and wear ring. Measure each blade at its center.

Clearance should not exceed 1.0 mm (.040 in). If

clearance is greater, disassemble jet pump and

inspect impeller and wear ring. Renew worn

parts.

F01J0EA

1

TYPICAL — MEASURING FROM WATER INLET SIDE

1. Feeler gauge

F01J0FA

1

TYPICAL — MEASURING FROM VENTURI SIDE

1. Feeler gauge

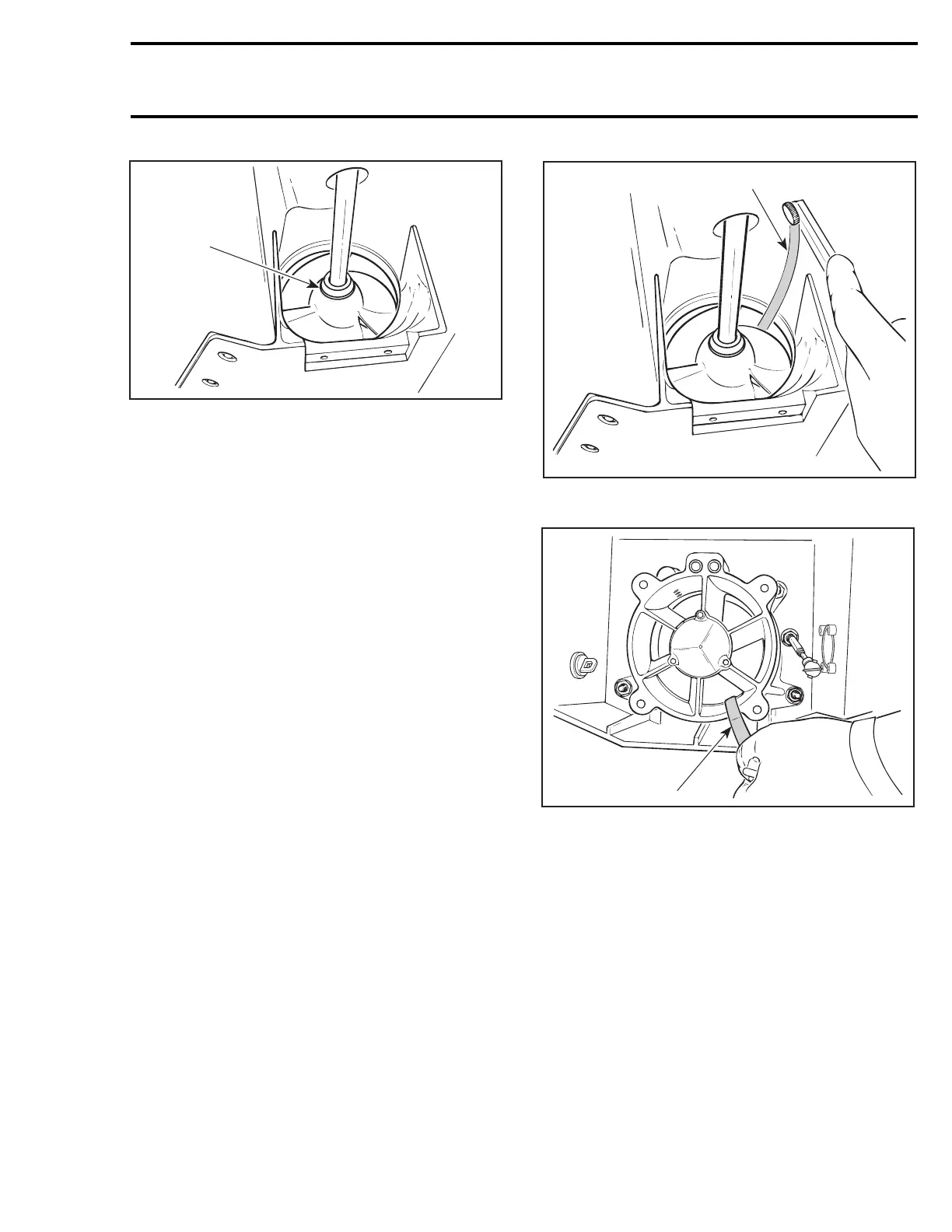

Oil Inspection

Remove:

– reverse gate cable

– VTS rod (if so equippped)

– steering cable

– screws no. 19 retaining venturi to the housing.

Pull venturi.

Remove plug from cover.

smr2004-Complete Line Up 617

Loading...

Loading...