Section 13 PROPULSION

Subsection 02 (DRIVE SYSTEM)

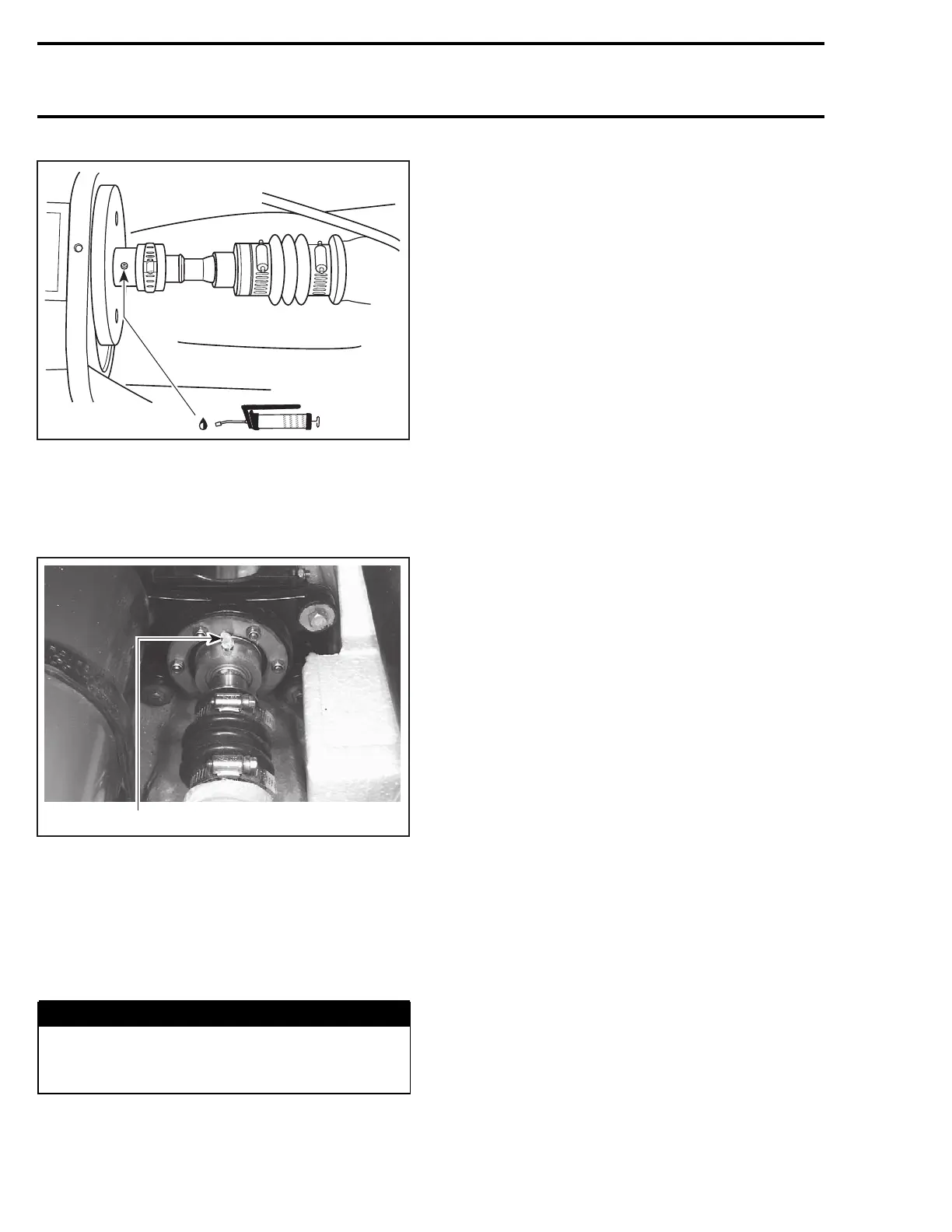

F01I0BB

Seal Carrier of Mid Bearing

XP DI Models

Using a grease gun, lubricate seal carrier of mid

bearing with synthetic grease (P/N 293 550 010).

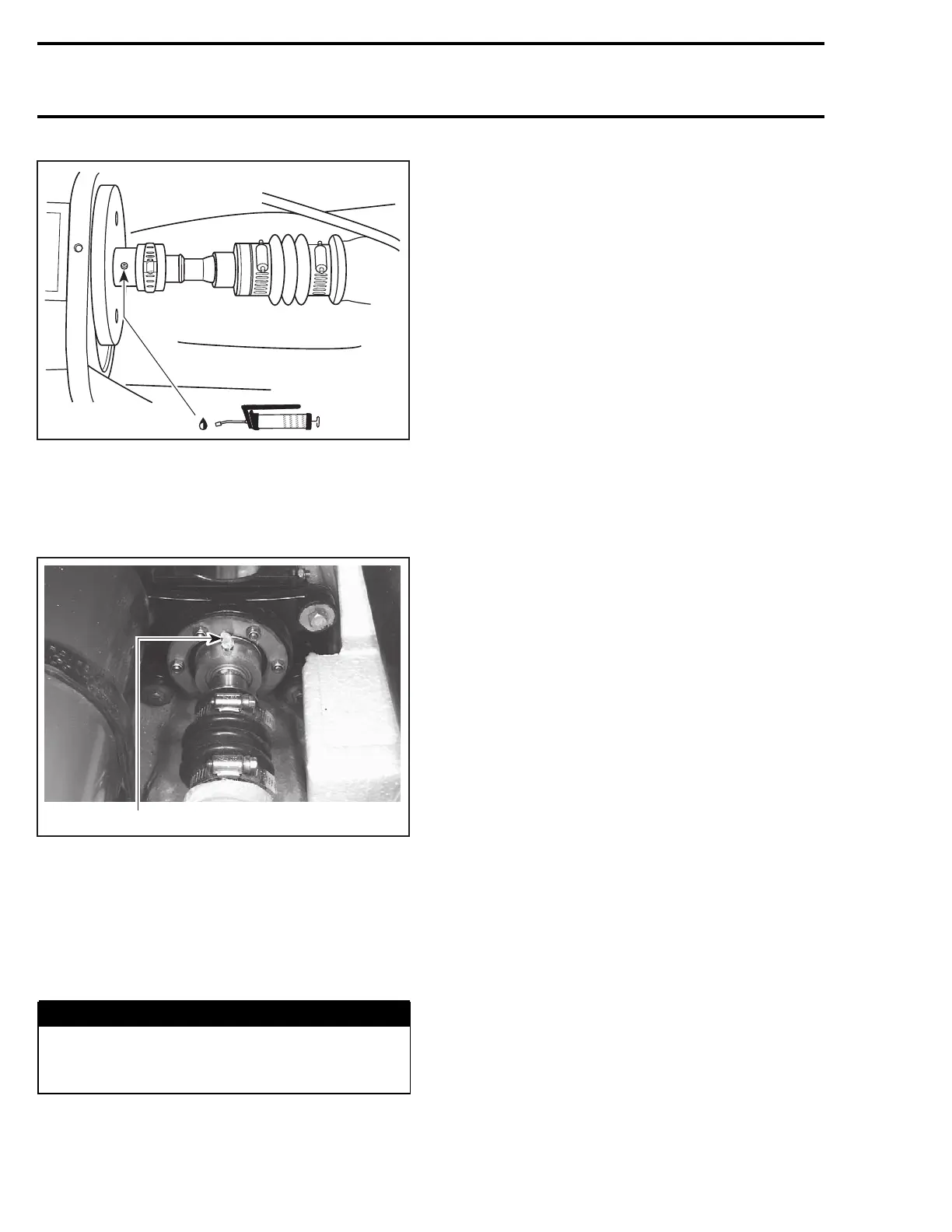

F05I09A

1

TYPICAL

1. Grease fitting

Corrosion Protection

4-TEC Models

To prevent possible drive shaft corrosion, apply an-

ti-corrosion spray (P/N 219 700 304) as described

here.

WARNING

Always work in a well ventilated area. Care-

fully read application instructions on product

can.

If drive shaft has been removed and lubricated be-

fore installation, nothing more is required. Other-

wise, proceed as follows.

Drive shaft should be dry and clean prior to apply-

ing the corrosion protectant.

Place a plastic sheet underneath hull to recover

the excess of sprayed corrosion protectant.

From underneath hull, spray the corrosion protec-

tant through the intake grate all over the visible

portion of drive shaft.

Dispose of the soiled plastic sheet as per your lo-

cal environmental regulations.

NOTE: On Supercharged models, remove inlet

hose from supercharger to gain access.

From inside bilge, lift splash guard to expose PTO

seal assembly.

Cover carbon seal ring and floating ring with a rag

or plastic wrap to prevent the protectant to reach

the carbon ring. Place a rag on bottom of hull

to recover the excess of sprayed corrosion pro-

tectant. Spray the visible portion of drive shaft.

When done, dispose soiled rag as per your local

environmental regulations.

NOTE: On Supercharged models, reinstall inlet

hose to supercharger.

Reposition splash guard.

Wait 2 hours prior to using the watercraft to allow

the protectant to dry.

674 smr2004-Complete Line Up

Loading...

Loading...