Parameter Description Issue 01/06

MICROMASTER 440 Parameter List

154 6SE6400-5BB00-0BP0

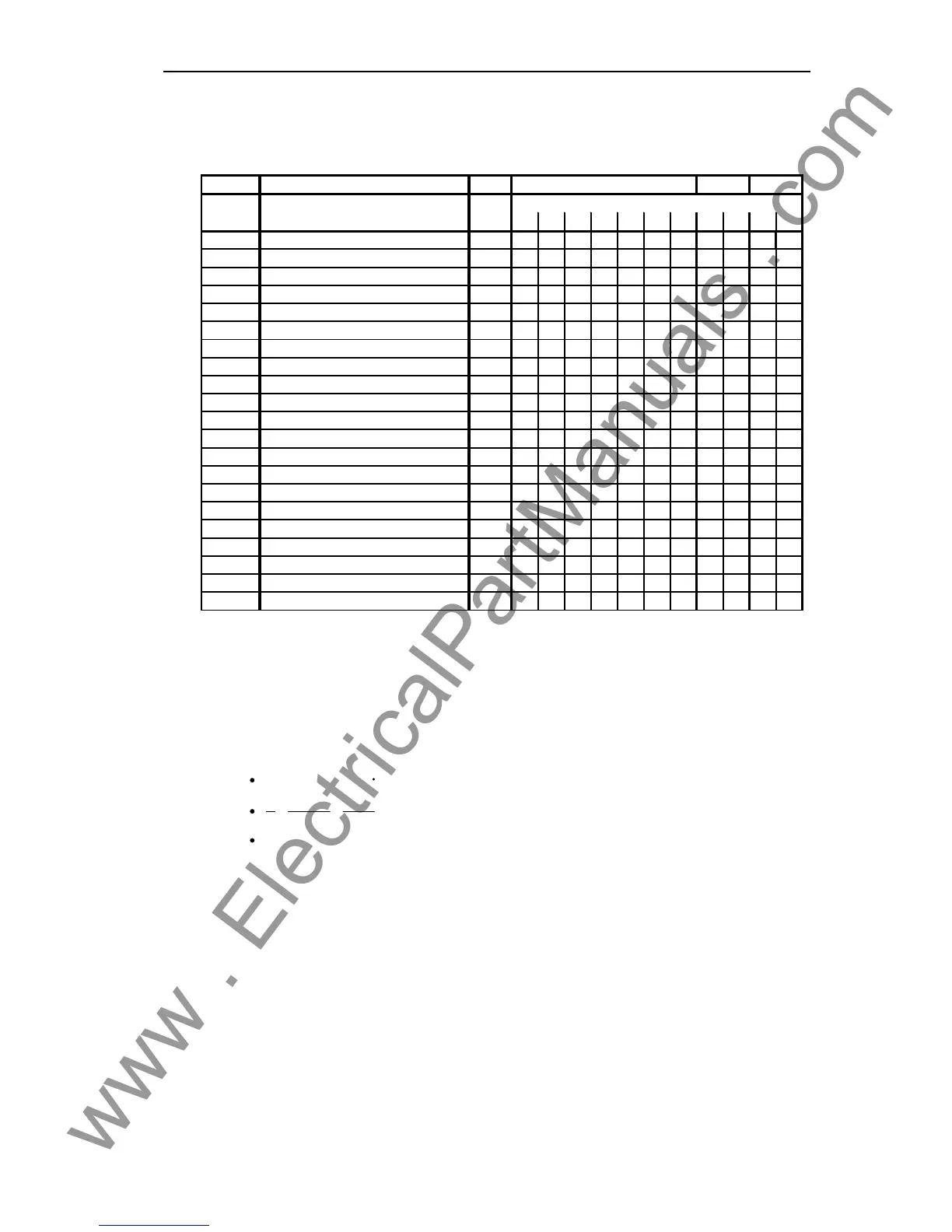

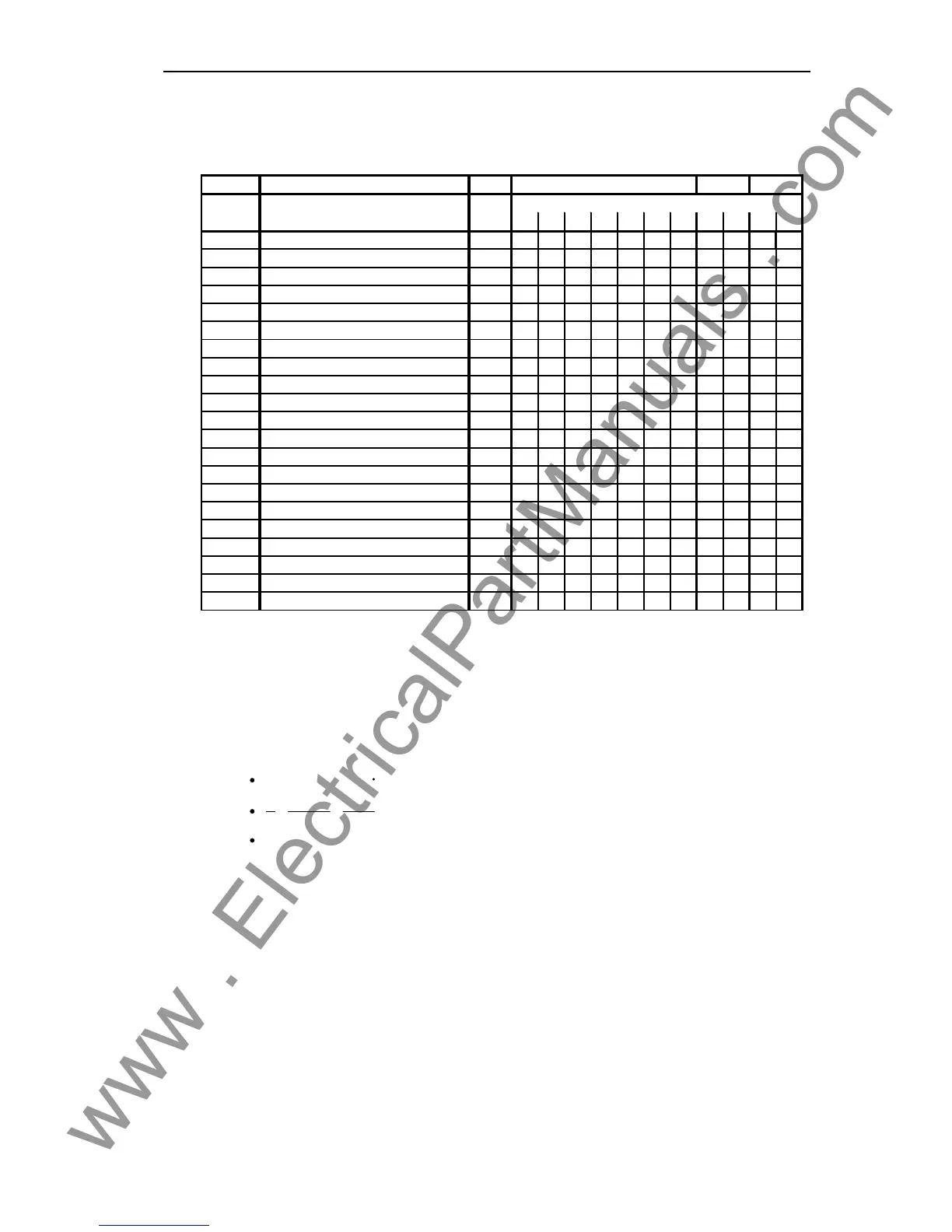

P1300 = 19 : V/f control with independent voltage setpoint

The following table presents an overview of control parameters (V/f) that can be modify in relationship to

P1300 dependencies:

ParNo. Level

0123561920222123

P1300[3] 2 x x x xxxxxxxx

P1310[3] 2 x x x xxxx

−−−−

P1311[3] 2 x x x xxxx

−−−−

P1312[3] 2 x x x xxxx

−−−−

P1316[3] 3 x x x xxxx

−−−−

P1320[3] 3

−−−

x

−−−−−−−

P1321[3] 3

−−−

x

−−−−−−−

P1322[3] 3

−−−

x

−−−−−−−

P1323[3] 3

−−−

x

−−−−−−−

P1324[3] 3

−−−

x

−−−−−−−

P1325[3] 3

−−−

x

−−−−−−−

P1330[3] 3

−−−−−−

x

−−−−

P1333[3] 3

−

x

−−−

x

−−−−−

P1335[3] 2 x x x x

−−−−−−−

P1336[3] 2 x x x x

−−−−−−−

P1338[3] 3 x x x x

−−−−−−−

P1340[3] 3 x x x xxxx

−−−−

P1341[3] 3 x x x xxxx

−−−−

P1345[3] 3 x x x xxxx

−−−−

P1346[3] 3 x x x xxxx

−−−−

P1350[3] 3 x x x xxxx

−−−−

U/f SLVC VC

P1300 =

Parameter name

Control mode

Continuous boost

Acceleration boost

Starting boost

Boost end frequency

Programmable V/f freq. coord. 1

Programmable V/f volt. coord. 1

Programmable V/f freq. coord. 2

Programmable V/f volt. coord. 2

Programmable V/f freq. coord. 3

CI: Voltage setpoint

Start frequency for FCC

Slip compensation

CO: U/f Slip limit

Resonance damping gain V/f

Imax freq. controller prop. gain

Imax controller integral time

Imax controller prop. gain

Imax voltage ctrl. integral time

Voltage soft start

Programmable V/f volt. coord. 3

V/f

SLVC / VC can provide excellent performance for the following types of application:

- Applications which require high torque performance

- Applications which require fast respond to shock loading

- Applications which require torque holding while passing through 0 Hz

- Applications which require very accurate speed holding

- Applications which require motor pull out protection

SLVC/VC-Restrictions:

- SLVC / VC is dependent on the accuracy of the motor model being used and the measurements being

performed by the inverter. There are therefore certain restrictions on the use of SLVC / VC:

(max. frequency)f

max

= min(200 Hz, 5 P0310)

r0207

r0209

r0207

P0305

4

1

≤≤

(ratio of rated motor current to rated inverter current)

no synchronuos motor

Recommended means of SLVC/VC-commissioning:

- For correct operation under SLVC / VC control it is imperative that the name plate data of the motor

(P0304 - P0310) is correctly entered and that the motor data identification (P1910) must be carried out

on a cold motor. It is also necessary to ensure that the motor ambient temperature is correctly entered

in P0625 if this is significantly different from the default value of 20°C. This must be done after the quick

commissioning has been completed (P3900) but before the motor data identification measurements are

carried out.

- See parameter P0400 and documentation of encoder and encoder module when commissioning VC

(P1300 = 21 or 23).

SLVC/VC-Optimisation:

The following parameters can be adjusted by the user to improve performance.

- P0003 = 3

- P0342: Total / motor inertia ratio

Sensorless Vector Control (SLVC):

- P1470: P gain (SLVC)

- P1472: I term (SLVC)

- P1610: Continuous torque boost (SLVC, open loop boost)

- P1611: Acceleration torque boost (SLVC, open loop boost)

- P1750: Control word of motor model

- P1755: Start-frequency motor model (SLVC)

Loading...

Loading...