Issue 01/06 Parameter Description

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

239

P2354 PID tuning timeout length Min: 60

CStat: CUT Datatype: U16 Unit: s Def: 240

P-Group: TECH Active: Immediately QuickComm.: No Max: 65000

This parameter determines the time that the auto tuning code will wait before aborting a tuning run if no

oscillation has been obtained.

P2355 PID tuning offset Min: 0.00

CStat: CUT Datatype: Float Unit: % Def: 5.00

P-Group: TECH Active: Immediately QuickComm.: No Max: 20.00

Sets applied offset and deviation for PID autotuning.

Note:

This can be varied depending on plant conditions e.g. a very long system time constant might require a

larger value.

3.38 Positioning down ramp

P2480[3] Position mode Min: 1

CStat: CT Datatype: U16 Unit: - Def: 1

P-Group: CONTROL Active: first confirm QuickComm.: No Max: 1

Sets the mode for positioning mode.

Possible Settings:

1 Open loop positioning

Index:

P2480[0] : 1st. Drive data set (DDS)

P2480[1] : 2nd. Drive data set (DDS)

P2480[2] : 3rd. Drive data set (DDS)

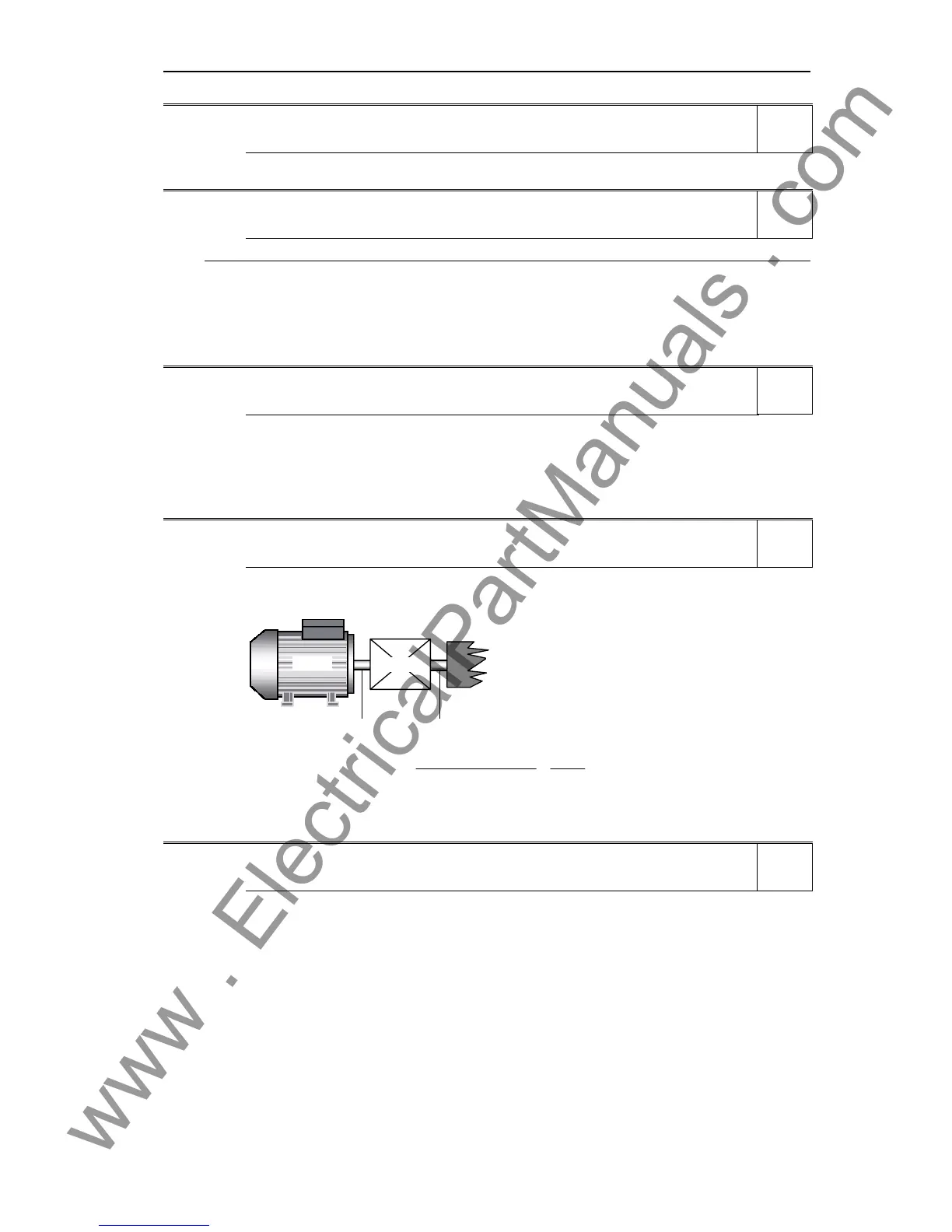

P2481[3] Gearbox ratio input Min: 0.01

CStat: CUT Datatype: Float Unit: - Def: 1.00

P-Group: CONTROL Active: first confirm QuickComm.: No Max: 9999.99

Defines the ratio between number of motor shaft revolutions to equal one revolution of the gearbox output

shaft.

n n

Motor Load

Load

Ü

Ü =

P2482

P2481

=

Motor revolutions

Load revolutions

Motor

Gear

Index:

P2481[0] : 1st. Drive data set (DDS)

P2481[1] : 2nd. Drive data set (DDS)

P2481[2] : 3rd. Drive data set (DDS)

P2482[3] Gearbox ratio output Min: 0.01

CStat: CUT Datatype: Float Unit: - Def: 1.00

P-Group: CONTROL Active: first confirm QuickComm.: No Max: 9999.99

Defines the ratio between number of motor shaft revolutions to equal one revolution of the gearbox output

shaft.

Index:

P2482[0] : 1st. Drive data set (DDS)

P2482[1] : 2nd. Drive data set (DDS)

P2482[2] : 3rd. Drive data set (DDS)

Level

3

Level

3

Level

3

Level

3

Level

3

Loading...

Loading...