Issue 01/06 Parameter Description

MICROMASTER 440 Parameter List

6SE6400-5BB00-0BP0

231

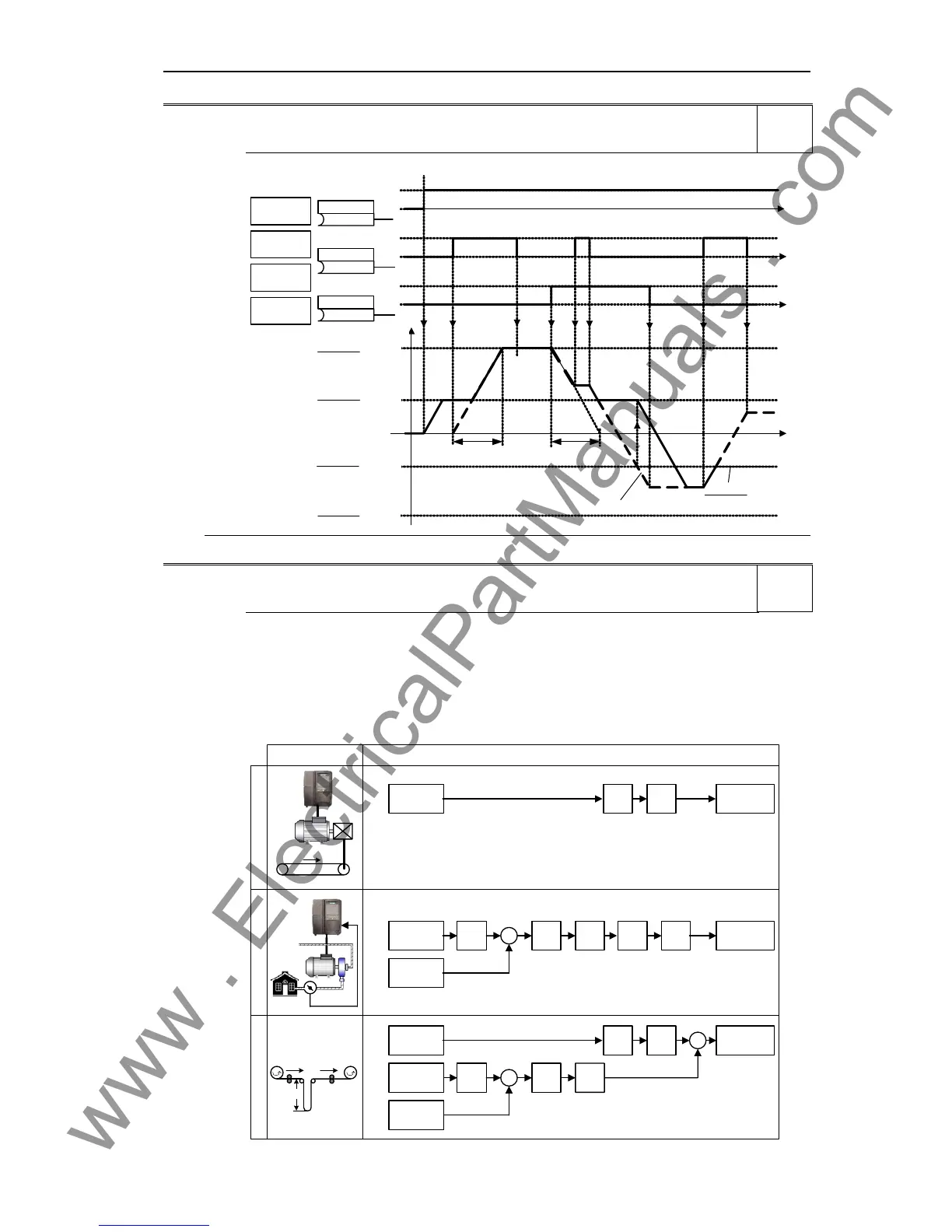

r2250 CO: Output setpoint of PID-MOP Min: -

Datatype: Float Unit: % Def: -

P-Group: TECH Max: -

Displays output setpoint of motor potentiometer in [%].

% 100

P2000

f

act

⋅

1

0

1

0

t

t

t

DIN

BOP

USS

CB

COM link

1

0

t

P2235

P2236

P0840

r2250

% 100

P2000

P1080

⋅

% 100

P2000

P1082

⋅

% 100

P2000

P1080

⋅−

% 100

P2000

P1082

⋅−

%

Note:

r2250 = 100 % corresponds to 4000 hex

P2251 PID mode Min: 0

CStat: CT Datatype: U16 Unit: - Def: 0

P-Group: TECH Active: Immediately QuickComm.: No Max: 1

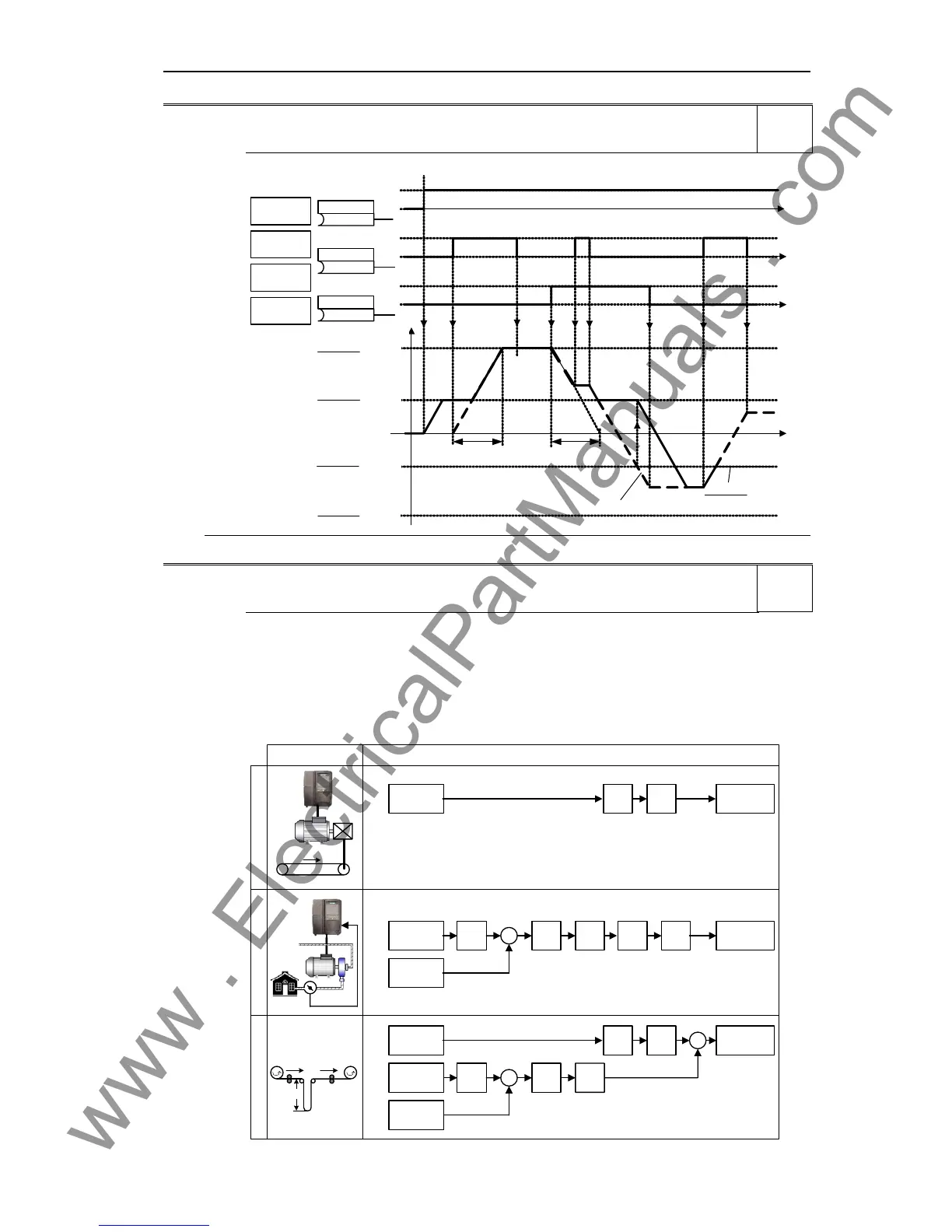

Configuration of PID controller.

Possible Settings:

0 PID as setpoint

1 PID as trim

Common Settings:

In addition to the open-loop/closed-loop control of a three-phase motor (standard applications for a drive

inverter), MICROMASTER has a technological controller that can be used to control (closed-loop) process

quantities such as pressure, filling level or control a winder. These applications and the closed-loop control

structures required to implement these are shown in the following diagram.

Application Control structure

SUM

setpoint

PID

RFG

PID

AFM RFG

x

2

v

2

v

1

4

2

PID

setpoint

PID

feedback

PID

RFG

PID

PID

limit

AFM RFG

v

2

*

x

2

*

x

2

p

2

*

p

2

−

−

PID

setpoint

PID

feedback

PID

limit

Motor

control

Motor

control

PID control

Dancer control

Variable speed drive (VSD)

1

3

p

2

SUM

setpoint

AFM RFG

Motor

control

v

Level

2

Level

3

Loading...

Loading...