Technology instructions

10.2 PID control

S7-1200 Programmable controller

System Manual, V4.2, 09/2016, A5E02486680-AK

619

A slave in a cascade gets its setpoint from the output of his master. If the slave reaches its

own output limits while the master still sees a control deviation (setpoint – input), the master

freezes or reduces its integration contribution to prevent a so-called "WindUp". In case of a

"WindUp", the master increases its integration contribution to a very large value and must

reduce it first, before the controller can again have a normal reaction. Such a "WindUp"

affects the dynamic of the control negatively. The PID_Temp provides ways to prevent this

effect in a cascade by configuring the parameter “Config.Cascade.AntiWindUpMode” of the

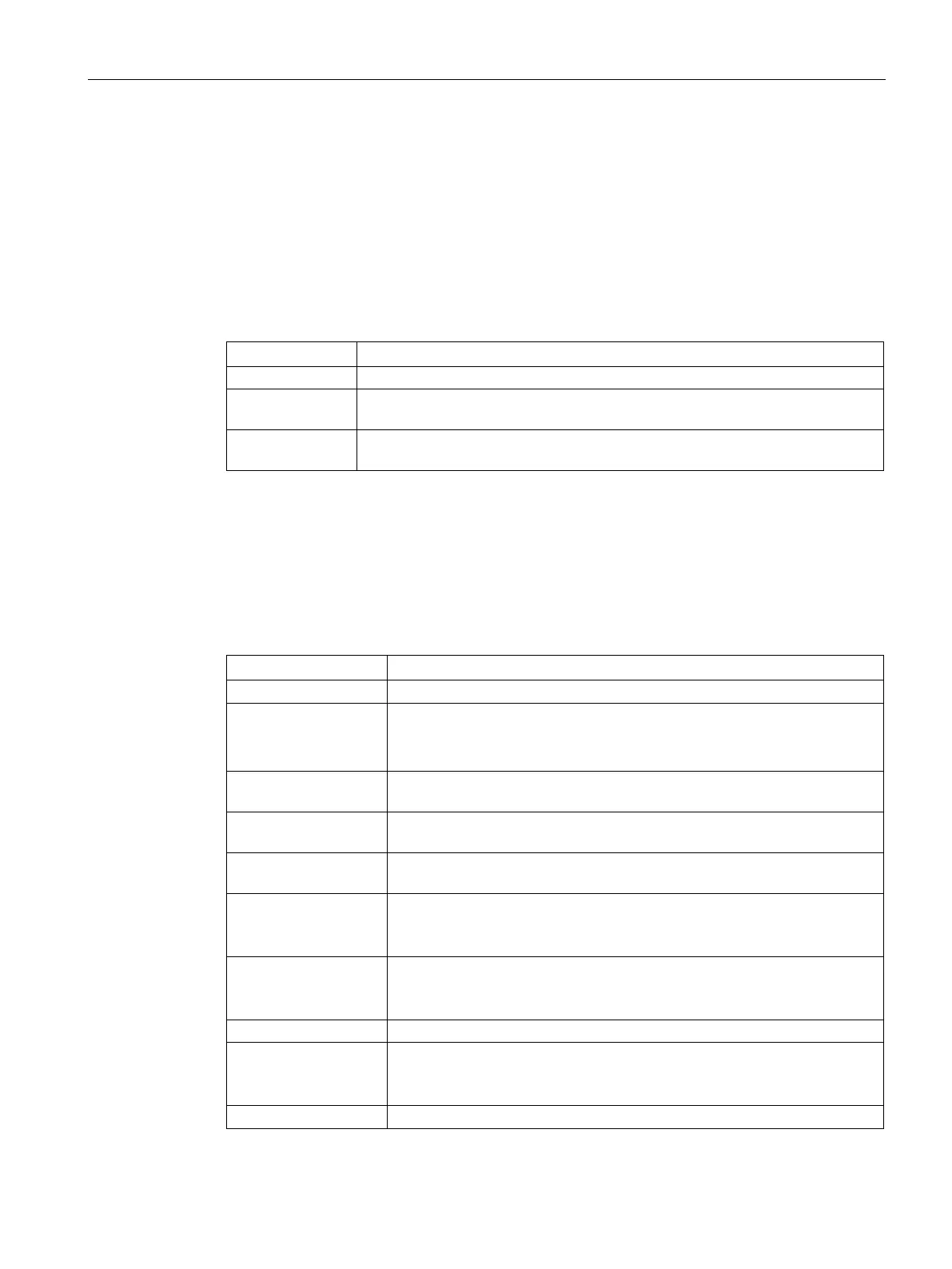

master controller:

Deactivates Anti-Windup functionality.

1 Reduces the integration contribution of the master controller at the ratio “slaves

in limitation” to “existing slaves” (parameter “CountSlaves”).

2 Freezes the integration contribution of the master as soon as one slave reaches

its limitation. Only relevant if "Config.Cascade.IsMaster" = TRUE.

PID_Temp ErrorBit parameters

If the PID controller has several warnings pending, it displays the values of the error codes

by means of binary addition. The display of error code 0003, for example, indicates that the

errors 0001 and 0002 are pending.

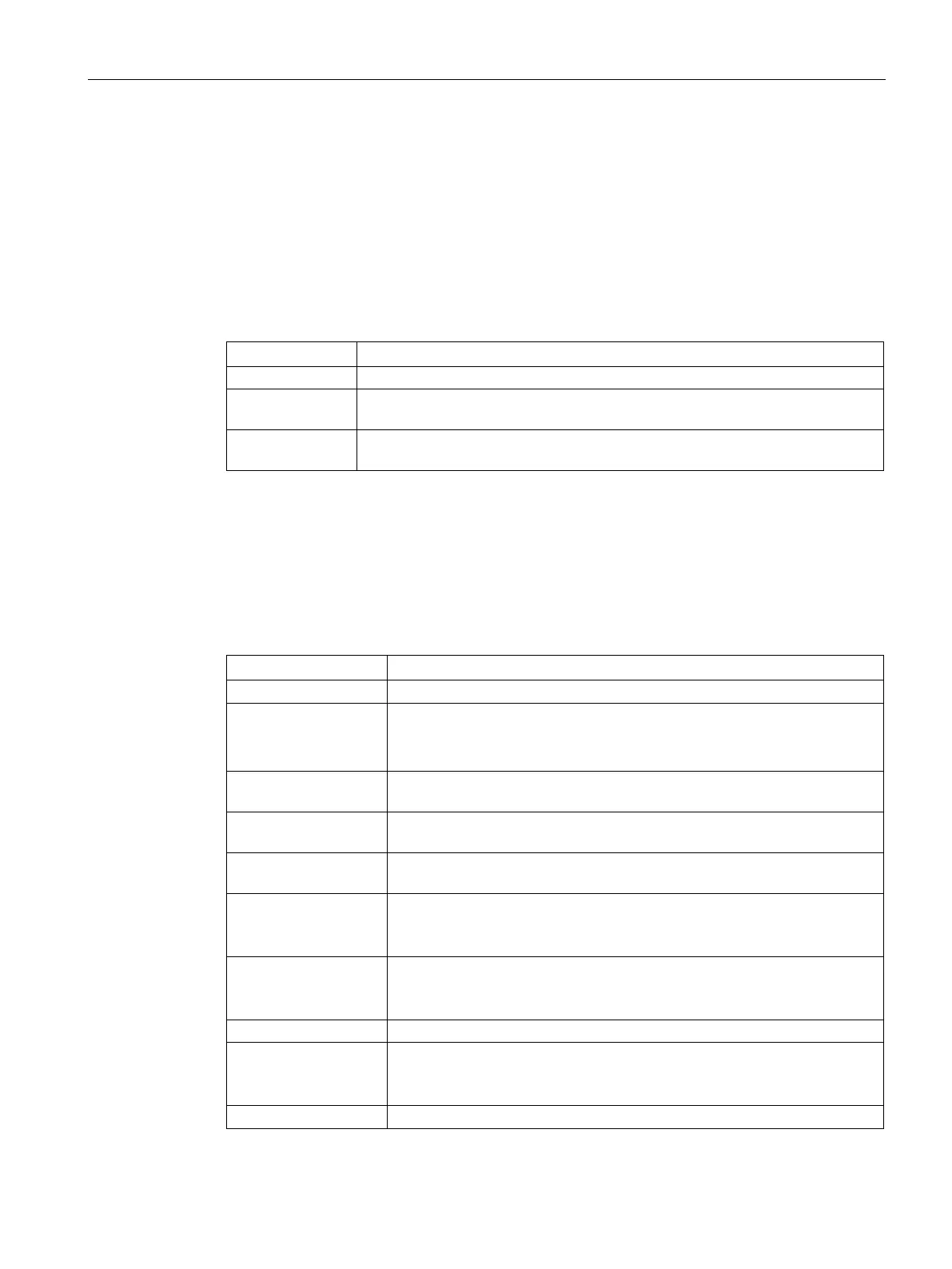

Table 10- 28 PID_Temp instruction ErrorBit parameters

0000 No error

0001

1, 2

The Input parameter is outside the process value limits.

Input > Config.InputUpperLimit

Input < Config.InputLowerLimit

0002

2, 3

Invalid value at the Input_PER parameter. Check whether an error is pend-

0004

4

Error during fine tuning. Oscillation of the process value could not be main-

0008

4

Error at start of pre-tuning. The process value is too close to the setpoint.

0010

4

The setpoint was changed during tuning.

Note: You can set the permitted fluctuation on the setpoint at the Cancel-

0020 Pre-tuning is not permitted during fine tuning.

Note: If ActivateRecoverMode = TRUE before the error occurred,

PID_Temp remains in fine tuning mode.

4

Error during pretuning. The cooling could not reduce the process value.

0080

4

Error during pre-tuning. Incorrect configuration of output value limits.

Check whether the limits of the output value are configured correctly and

0100

4

Error during fine tuning resulted in invalid parameters.

Loading...

Loading...