Technology instructions

10.3 Motion control

S7-1200 Programmable controller

756 System Manual, V4.2, 09/2016, A5E02486680-AK

Note

You can only use the MC_ChangeDynamic instruction for a drive connection using PTO

(Pulse Train Output).

An MC_ChangeDynamic command cannot be aborted by any other motion control

command.

A new MC_ChangeDynamic command does not abort any active motion control jobs.

Note

The input parameters "RampUpTime", "RampDownTime", "EmergencyRampTime" and

"RoundingOf

fTime" can be specified with values that makes the resultant axis parameters

"acceleration", "delay", "emergency stop

-delay" and "jerk" outside the permissible limits.

Make sure you keep the MC_ChangeDynamic parameters within the limits of the dynamic

conf

iguration settings for the axis technology object.

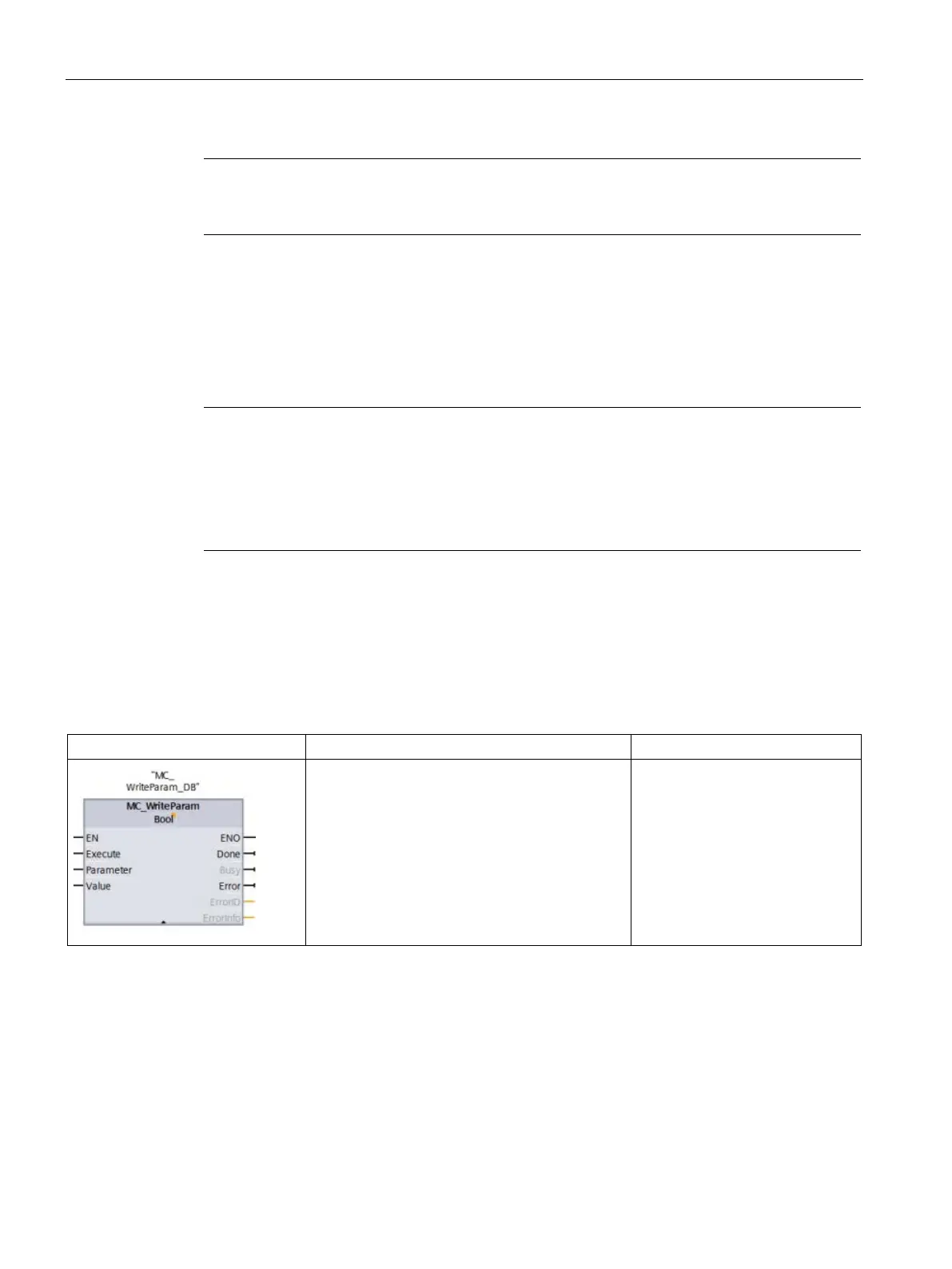

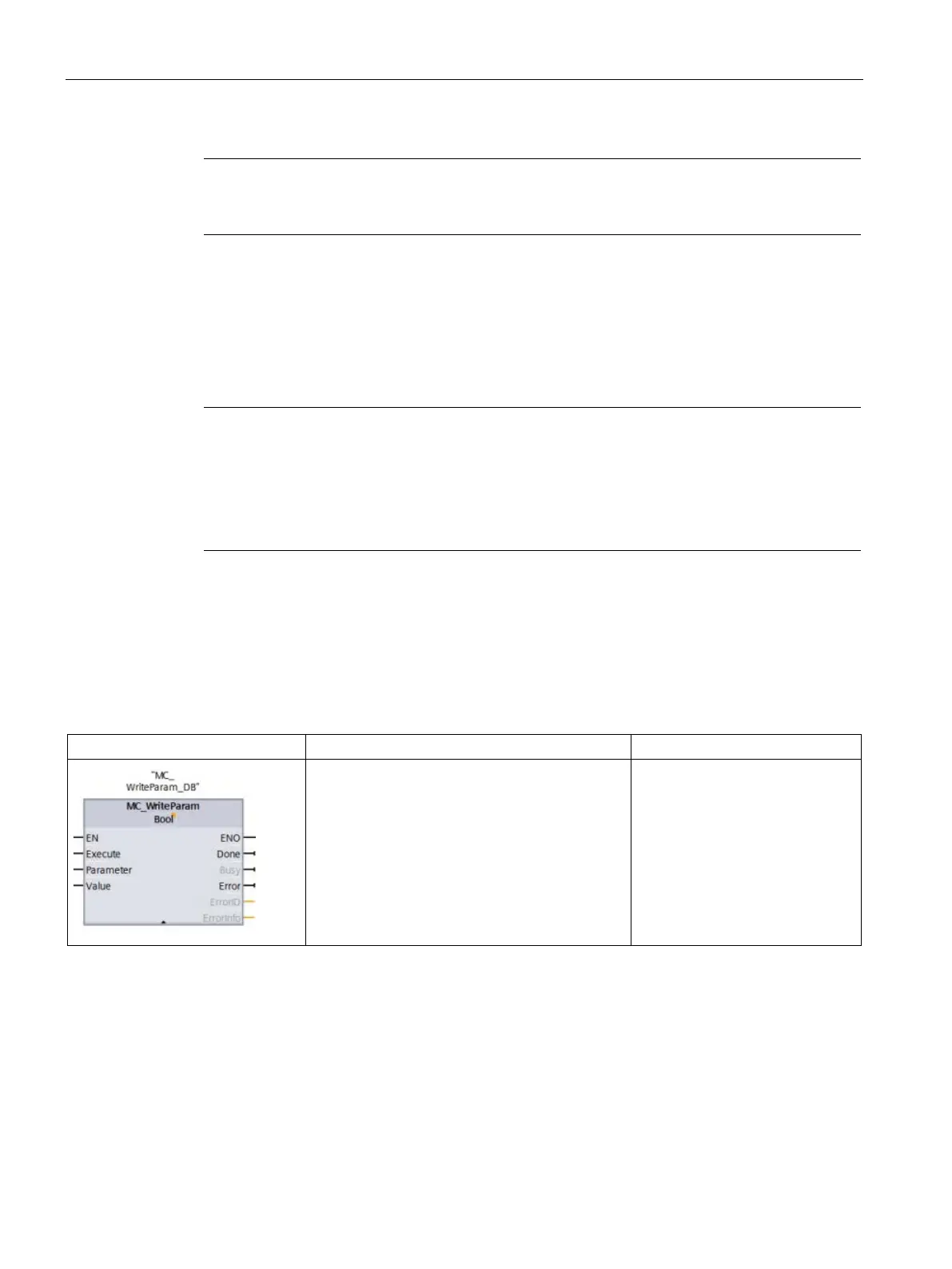

MC_WriteParam (write parameters of a technology object)

You use the MC_WriteParam instruction to write a select number of parameters to change

the functionality of the axis from the user program.

Table 10- 77 MC_WriteParam instruction

Parameter:=_variant_in_,

Value:=_variant_in_,

Execute:=_bool_in_,

Done:=_bool_out_,

Error:=_real_out_,

ErrorID:=_word_out_,

ErrorInfo:=_word_out_);

You use the MC_WriteParam

instruction to write to public pa-

rameters (for example, accelera-

tion and user DB values).

STEP 7 automatically creates the DB when you insert the instruction.

2

In the SCL example, "MC_WriteParam_DB" is the name of the instance DB.

Loading...

Loading...