Technology instructions

10.2 PID control

S7-1200 Programmable controller

610 System Manual, V4.2, 09/2016, A5E02486680-AK

The PID_Temp instruction provides a universal PID controller that allows handling of the

specific requirements of temperature control.

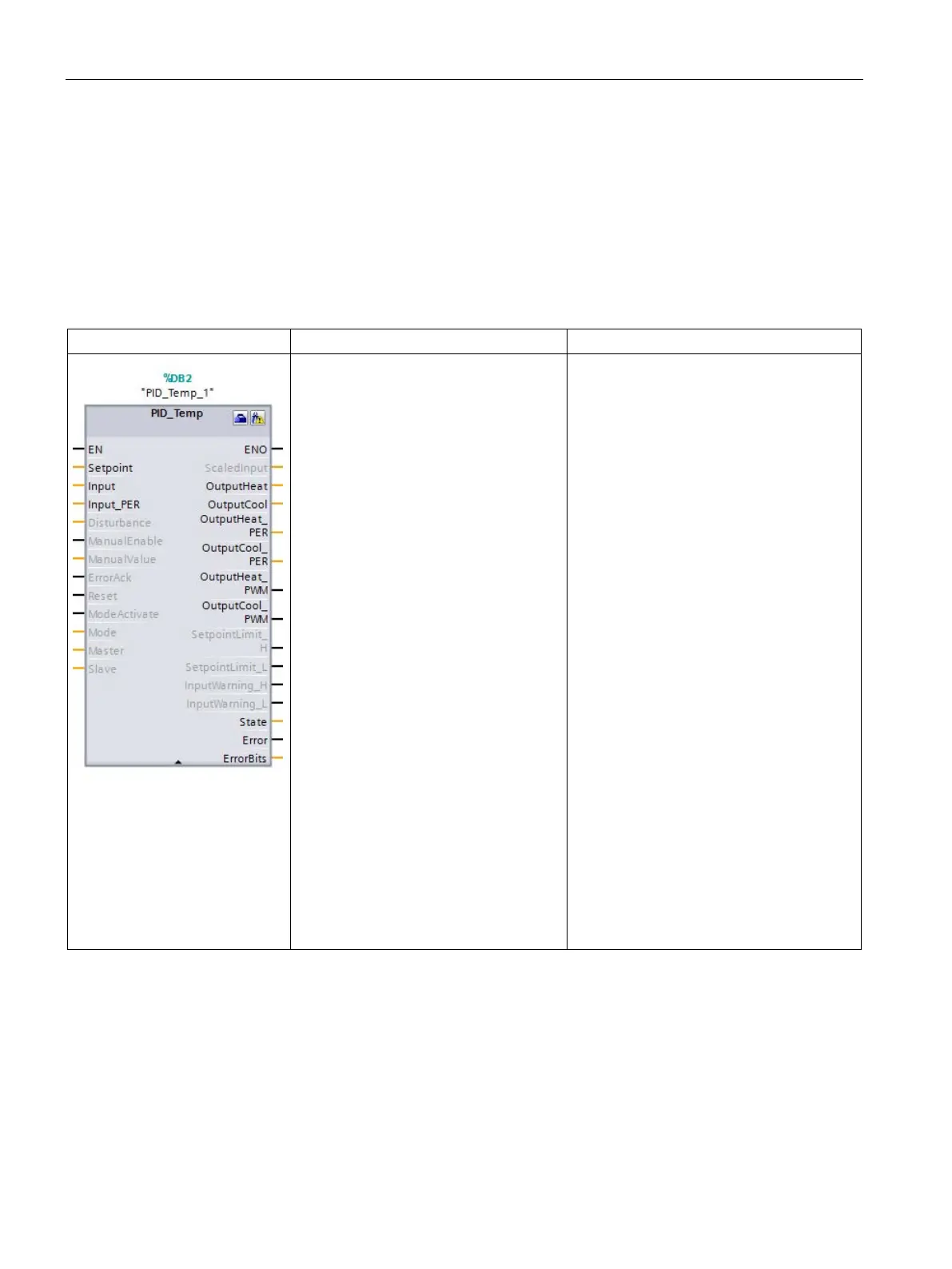

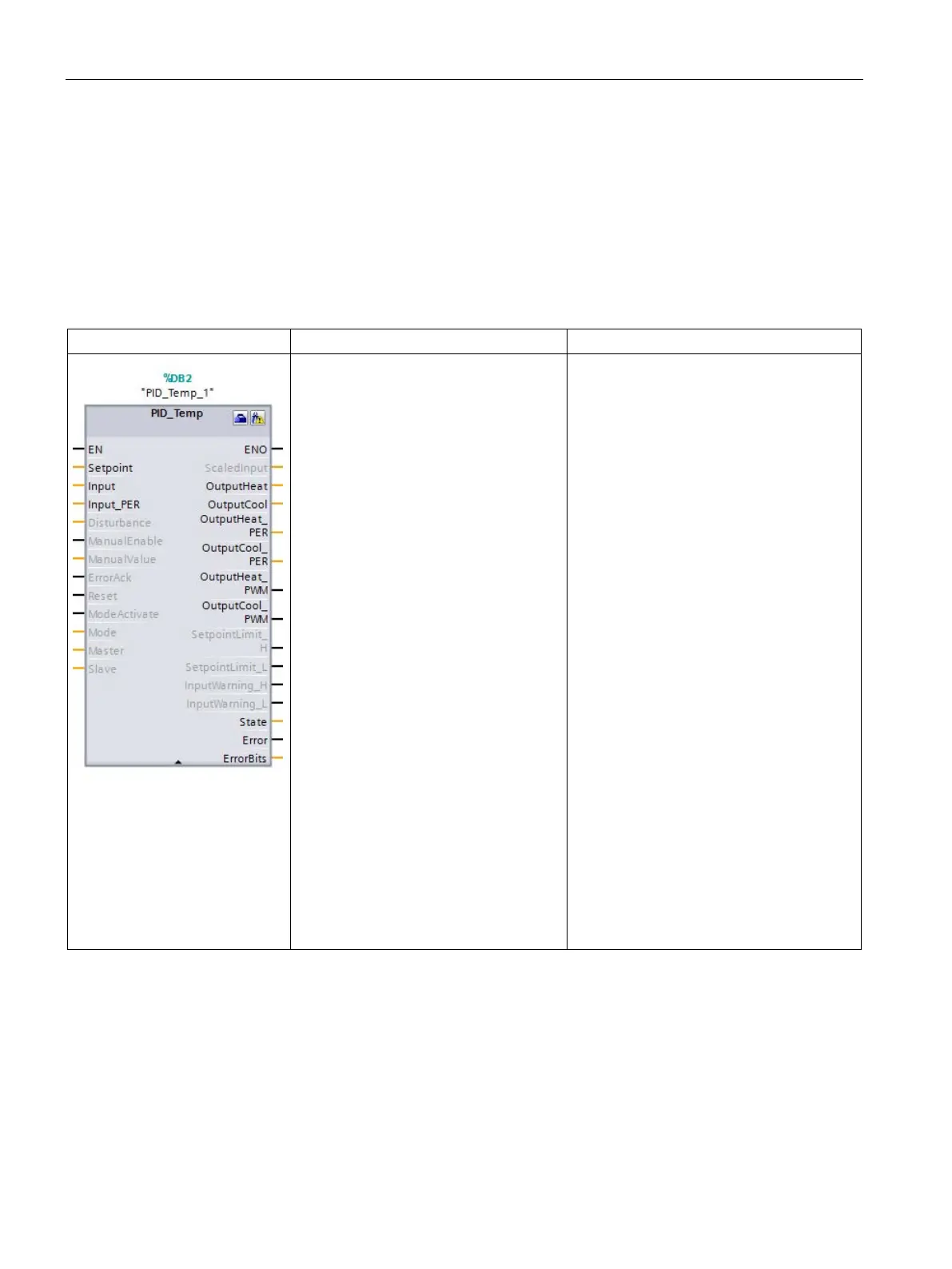

Table 10- 26 PID_Temp instruction

Setpoint:=_real_in_,

Input:=_real_in_,

Input_PER:=_int_in_,

Disturbance:=_real_in_,

ManualEnable:=_bool_in_,

ManualValue:=_real_in_,

ErrorAck:=_bool_in_,

Reset:=_bool_in_,

ModeActivate:=_bool_in_,

Mode:=_int_in_,

Master:=_dword_in

Save:=_dword_in

ScaledInput=>_real_out_,

OutputHeat=>_real_out_,

OutputCool=>_real_out_,

OutputHeat_PER=>_int_out_,

OutputCool_PER=>_int_out_,

Out-

putHeat_PWM=>_bool_out_,

Out-

putCool_PWM=>_bool_out_,

SetpointLimit_H=>_bool_out_,

SetpointLimit_L=>_bool_out_,

InputWarn-

ing_H=>_bool_out_,

InputWarn-

ing_L=>_bool_out_,

State=>_int_out_,

Error=>_bool_out_,

PID_Temp provides these capabilities:

• Heating and cooling of the process with

different actuators

• Integrated autotuning to handle temper-

ature processes

• Cascading to process more than one

temperature that depends on the same

actuator

STEP 7 automatically creates the technology object and instance DB when you insert the instruction. The instance DB

contains the parameters of the technology object.

2

In the SCL example, "PID_Temp_1" is the name of the instance DB.

Loading...

Loading...