PLC concepts

5.3 Processing of analog values

S7-1200 Programmable controller

System Manual, V4.2, 09/2016, A5E02486680-AK

123

Processing of analog values

Analog signal modules provide input signals or expect output values that represent either a

voltage range or a current range. These ranges are ±10 V, ±5 V, ±2.5 V, or 0 - 20 mA. The

values returned by the modules are integer values where 0 to 27648 represents the rated

range for current, and -27648 to 27648 for voltage. Anything outside the range represents

either an overflow or underflow. See the tables for analog input representation (Page 1471)

and analog output representation (Page 1472) for details about the types of out-of-range

values.

In your control program, you probably need to use these values in engineering units, for

example to represent a volume, temperature, weight or other quantitative value. To do this

for an analog input, you must first normalize the analog value to a real (floating point) value

from 0.0 to 1.0. Then you must scale it to the minimum and maximum values of the

engineering units that it represents. For values that are in engineering units that you need to

convert to an analog output value, you first normalize the value in engineering units to a

value between 0.0 and 1.0, and then scale it between 0 and 27648 or -27648 to 27648,

depending on the range of the analog module. STEP 7 provides the NORM_X and SCALE_X

instructions (Page 296) for this purpose. You can also use the CALCULATE instruction

(Page 255) to scale the analog values (Page 42).

Example: analog value processing

Consider, for example, an analog input that has a current range of 0 - 20 mA. The analog

input module returns values in the range 0 to 24768 for measured values. For this example,

consider that you are using this analog input value to measure a temperature range from

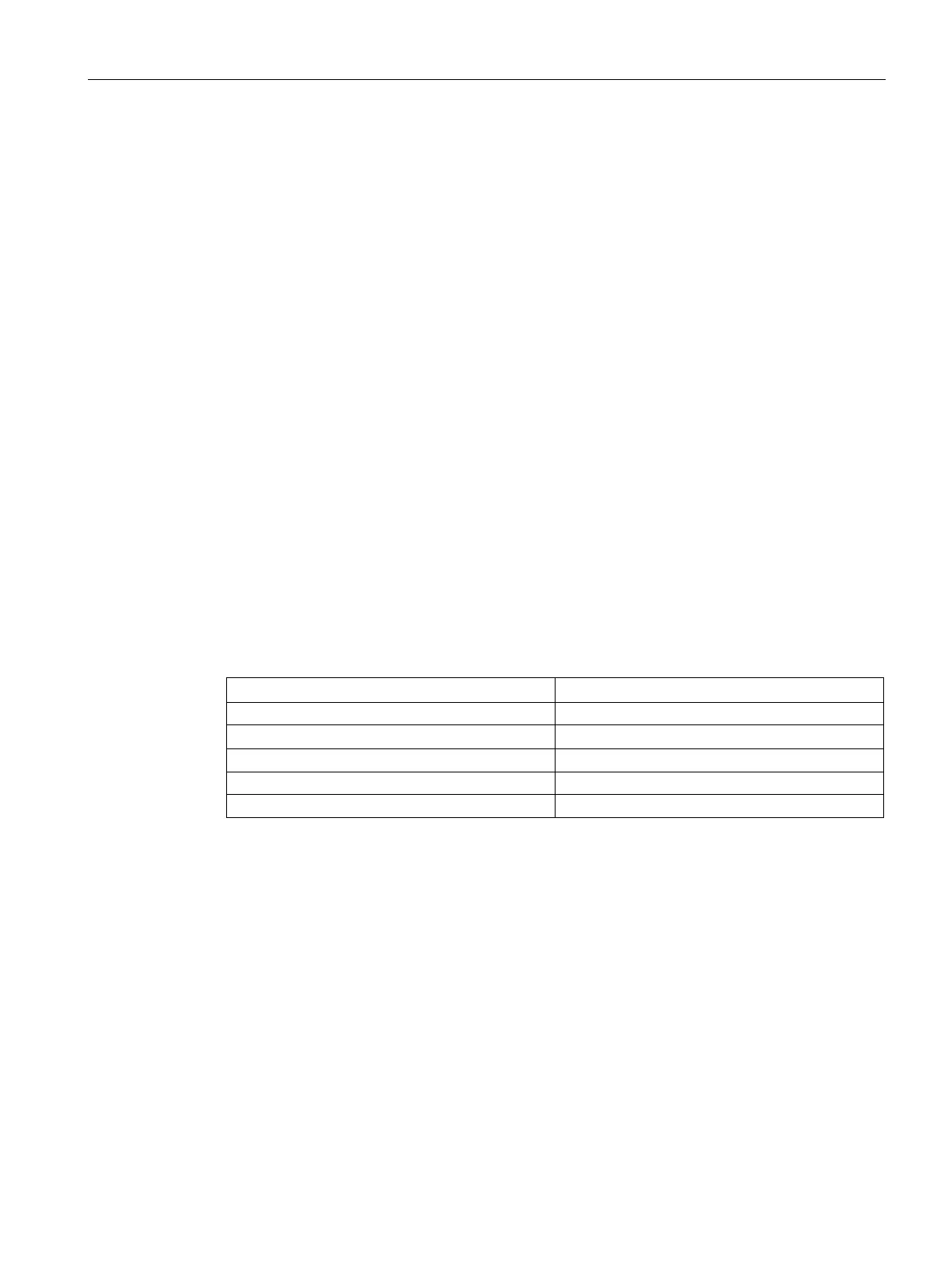

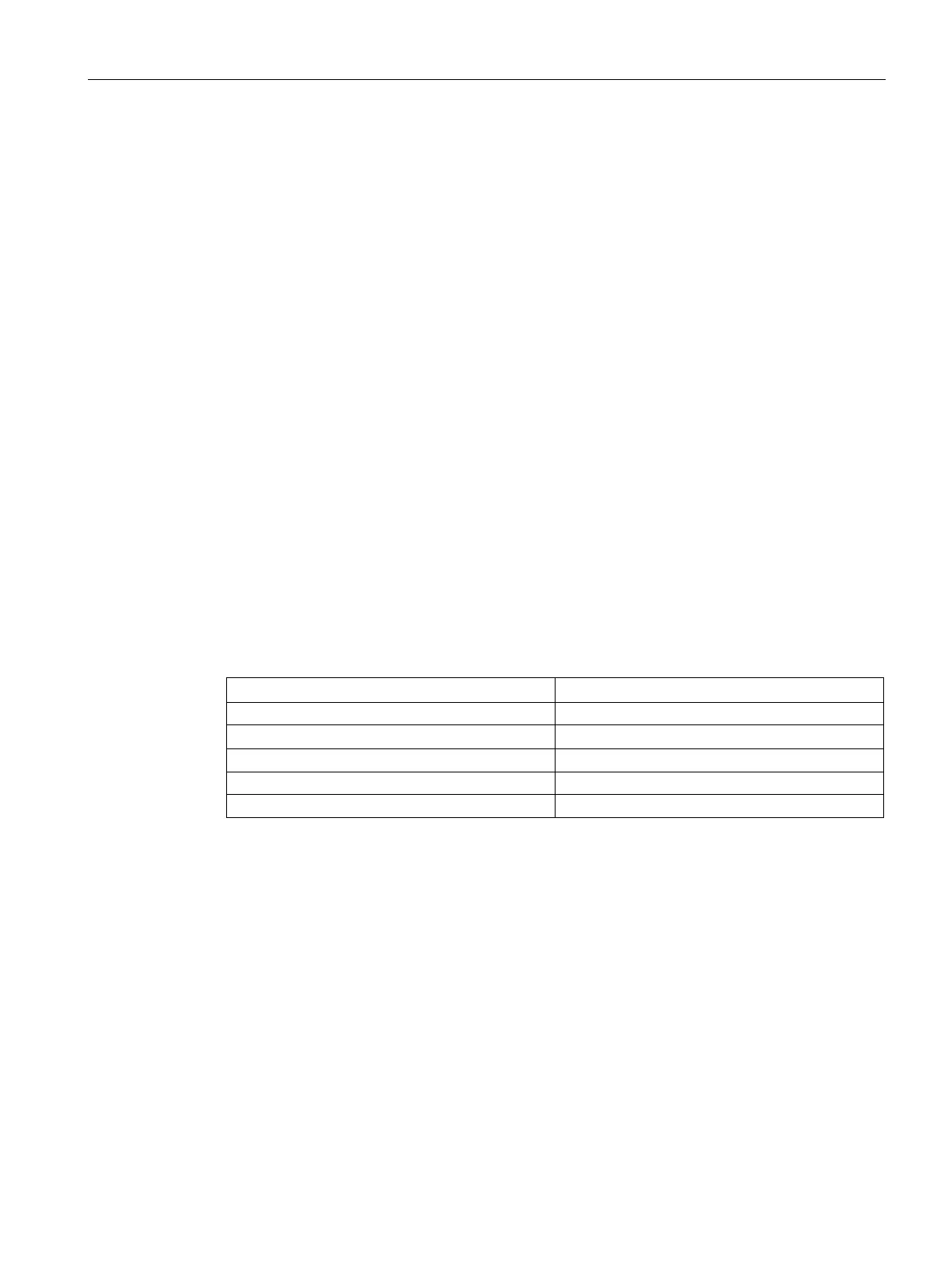

50 °C to 100 °C. A few sample values would have the following meanings:

6192 62.5 °C

The calculation for determining engineering units from the analog input value in this example

is as follows:

Engineering units value = 50 + (Analog input value) * (100 - 50) / (24768 - 0)

For the general case, the equation would be:

Englineering units value = (Low range of engineering units) +

(High range of engineering units

- Low range of engineering units) /

(Maximum analog input range - Minimum analog input range)

Loading...

Loading...