No. Parameter Name Description Setting Range Default Setting

L1-02

Motor Overload

Protection Time

Sets the electronic thermal overload protection detection time in the motor

overload protection (OL1) function.

This setting rarely needs to be changed and should be set in accordance with the

overload tolerance of the motor.

0.1 to 5.0 1.0 min

Note: Executing C6-01 (Duty Cycle) changes motor parameters E2 and E4 including motor rated current to the values of the maximum applicable motor.

Digital Outputs (H2-01 through H2-03)

Setting Function Description

1F

Motor Overload

OL1 Alarm Warning (including OH3)

Closed = When OL1 function is at 90% of its trip point or greater.

Setting Procedure

1.

Set E2-01 (Motor Rated Current) and E4-01 (Motor 2 Rated Current) to the motor rated current.

Note: 1. Values set for the current become the base current for electronic thermal overload protection.

2. These values are automatically set by performing Auto-Tuning.

3. The E4-01 setting is not needed if not using motor 2.

2.

Set the proper motor protection level to L1-01.

The ability of the cooling fan to keep an induction motor cool varies by the speed control range. Protection characteristics of the electronic thermal

overload protection should be set accordingly. Refer to

Table 4.21 for motor types and overload tolerances.

NOTICE: When connecting multiple motors to one drive, disable the electronic overload protection of the drive (L1-01 = 0) and protect each motor with its own motor

thermal overload. Failure to comply could result in improper drive operation.

NOTICE: Inadequate motor protection could result in damage to the motor. Configure a motor thermal overload to disconnect main power to the drive when tripped.

When using a thermal relay, disable the motor protection function (L1-01 = “0”).

3.

Set the motor overcurrent alarm warning level.

When H2-01, H2-02, and H2-03 (Terminal MA, MB, and MC Function selection, Terminal P1 Function Selection, and Terminal P2 Function

Selection) are set to 1F motor overload (OL1 alarm warning), a motor overload alarm is enabled. If the electronic thermal value exceeds 90% of

the overload detection level, the set output terminal turns on.

Table 4.21 Motor Type and Overload Tolerances

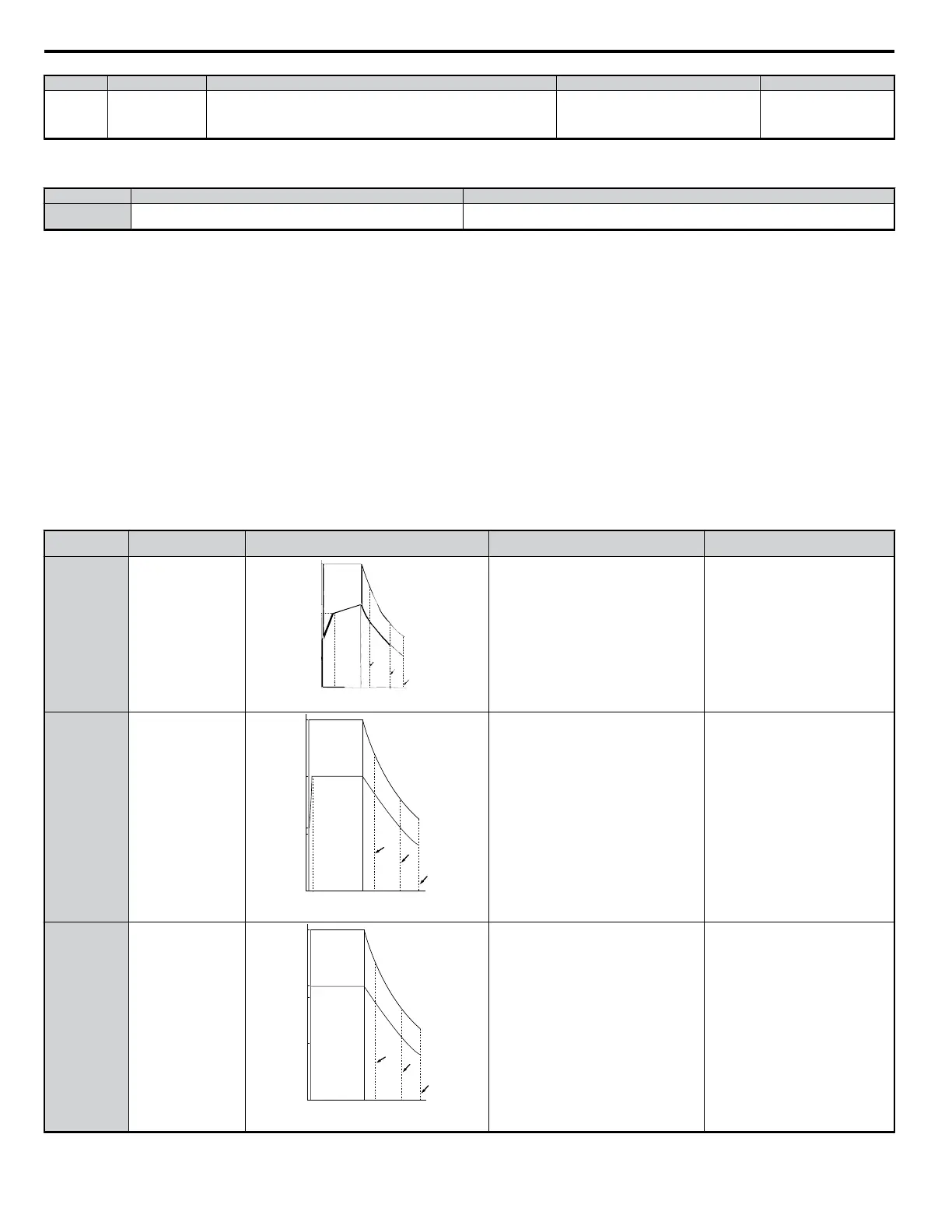

L1-01 Setting Motor Type Overload Tolerance Cooling Fan Capacity

Electrothermal Protection (100%

motor overload)

1

General-purpose motor

(standard motor)

100

150

90

60

50

Torque

(%)

60 seconds

Continuous

0 5 33 100

60Hz

120 167 200

(%)

Speed

C

B

Rated Speed = 100% Speed

A

General purpose motors are designed to operate

from line power. The most effective cooling

occurs when running at line power specifications.

Operating continuously at less than line

power frequency can trigger motor

overload protection (OL1). A fault is then

output and the motor will coast to stop.

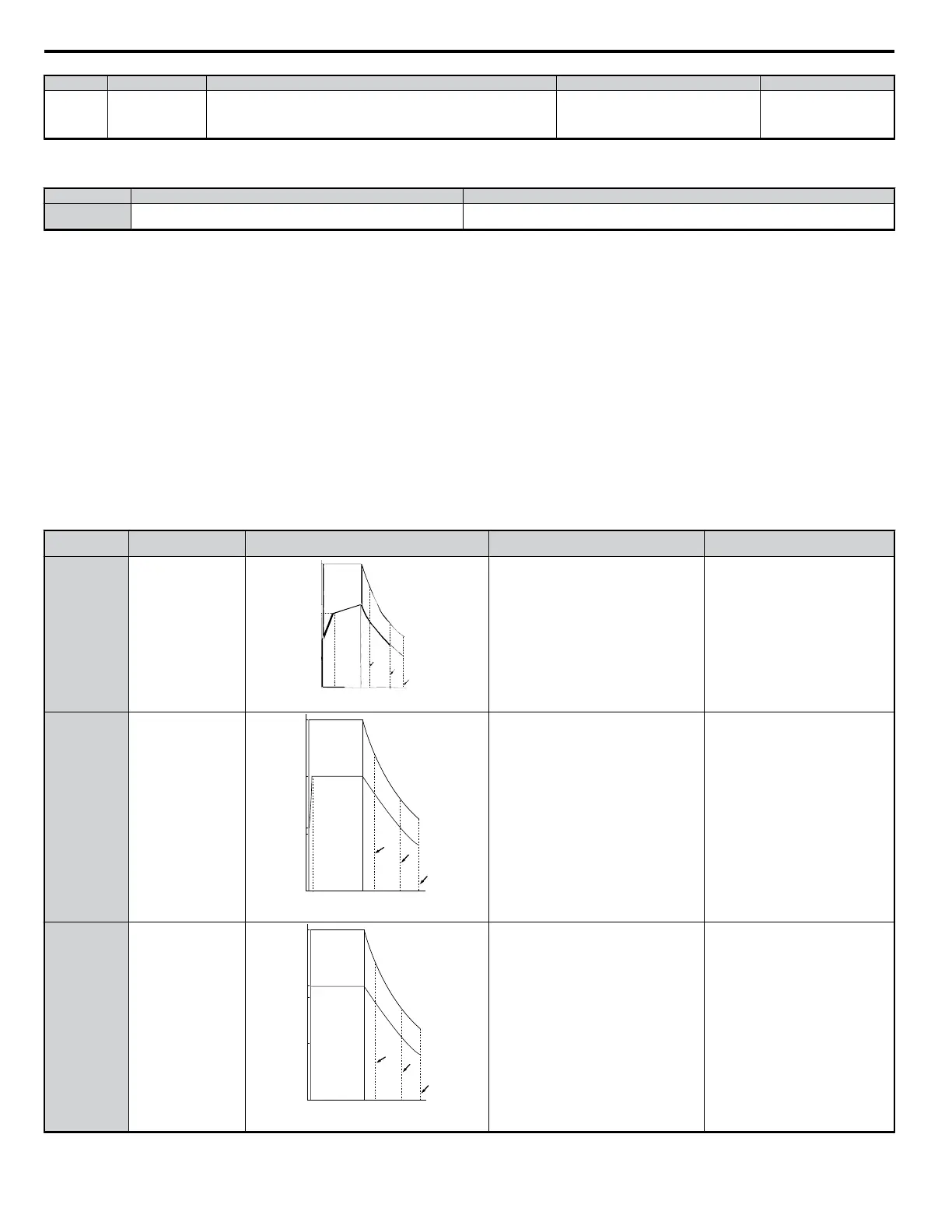

2

Inverter Duty motor

(1:10)

100

150

55

50

(%)

60 seconds

Continuous

0

1 10

100

(60Hz)

120 167 200

(%)

Speed

A

D

B

Rated Speed = 100% Speed

Torque

Motor designed to effectively self-cool at speeds

as low as 6 Hz.

Continuous operation between 6 and 50/60

Hz.

3 Vector motor (1:100)

90

A

B

D

100

150

50

(%)

60 seconds

Continuous

0

1

100

(60Hz)

120 167 200

(%)

Speed

Rated Speed = 100% Speed

Torque

Motor capable of effective cooling at extremely

low speeds (0.6 Hz).

Continuous operation between 0.6 and 60

Hz.

4.6 Basic Drive Setup Adjustments

88

YASKAWA ELECTRIC SIEP C710606 18A YASKAWA AC Drive – V1000 Technical Manual (Preliminary)

Loading...

Loading...