ESAB Cutting Systems

CROSSBOW Page 24

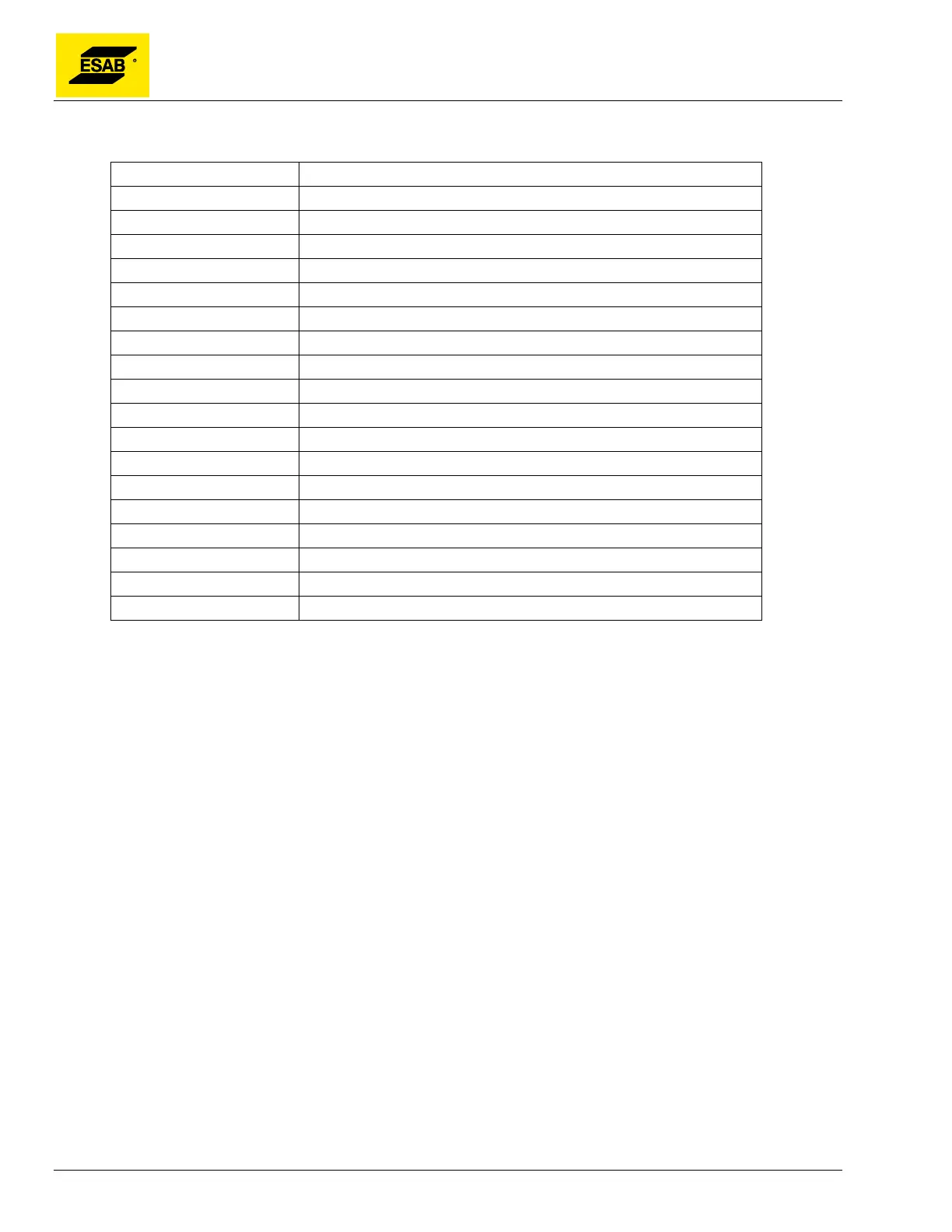

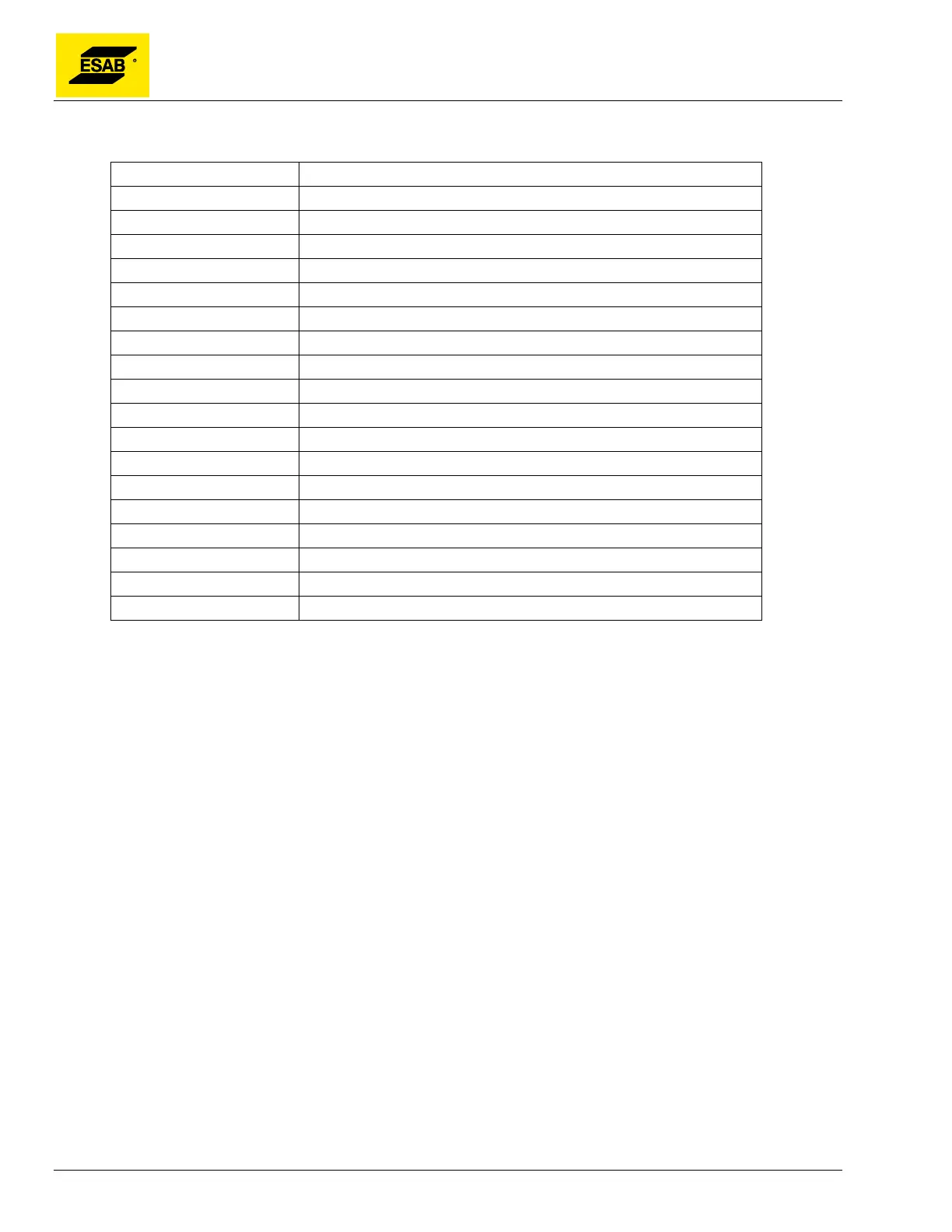

2.4 Machine Specifications

Input Voltage 110 / 220 VAC (internally selectable)

Frequency 50/60 Hz

Input Power Rating 180 W

Full Load Amperage 0.5 Amps

LCD screen size 178 mm (7 inch) diagonal, color

Central CNC Unit (L*W*H) 600 × 449 × 350 mm (23.6 × 17.7 × 13.8 in.)

Effective Cutting Width 1525 mm (5 ft.)

Overall Track Length 2200 or 4000 mm (86.6 or 157.5 in.)

Effective Cutting Length 1220 or 3100 mm (4 ft. or 10 ft.)

Rail Track Width 345 mm (13.6 in.)

Cutting Speed 0 – 3048 mm/min (0 – 120 ipm)

Flame Cutting Thickness 6 – 100 mm (1/4 – 4 in.)

Plasma Cutting Thickness 3 – 20 mm (1/8 – 3/4 in.) Depending on plasma power source

Central Unit Wight 27.6 Kb (61 lbs.)

Total Machine Weight 95.5 Kg (211 lbs.)

Gas Pressure 0 – 1 bar (0 – 15 psi)

Oxygen Pressure 0 – 10 bar (0 – 150 psi)

Gas Type Acetylene, Propane, or Natural Gas

Plasma Power Source ESAB PowerCut Series or ESP-101, featuring PT-37 torch

Notes:

• The Crossbow is equipped with a motorized torch lifter for easier, more automated operation. This

torch lifter allows plasma cutting to be automated through an Arc Voltage Height Control system.

However, when oxy-fuel cutting, there is no automatic height control, the torch must be positioned

manually and adjusted as required.

• The Crossbow may be supplied with or without an oxy-fuel torch. If supplied with a torch, it may

be supplied with the Oxweld C-69 torch for use with any fuel gas other than Acetylene, or it may

be supplied with the Oxweld C-70 torch for use with Acetylene only. The correct torch must be

ordered and used with the appropriate fuel gas. However, the torch may easily be changed if

necessary, along with all cutting tips.

Loading...

Loading...