ESAB Cutting Systems

CROSSBOW Page 88

4.15.5 【F6】REVERSE (Backward On Path)

Pressing 【F6】when paused will start the machine moving backwards along the programmed path, at

the Forward/Reverse Speed set in the Setup Menu, Speed parameters. Motion will continue along path

until 【STOP】is pressed, the machine reaches a pierce point, or the machine reaches a G00 (Program

Stop Code) in the program. The 【F6】key may be pressed again to continue backward on path at the

reduced Feed Rate.

4.15.6 【F7】FORWARD (Forward On Path)

Pressing 【F7】when paused will start the machine moving forwards along the programmed path, at

the Forward/Reverse Speed set in the Setup Menu, Speed parameters. Motion will continue along path

until 【STOP】is pressed, the machine reaches a pierce point, or the machine reaches a G00 (Program

Stop Code) in the program. The 【F7】key may be pressed again to continue forward on path at the

reduced Feed Rate.

4.15.7 Re-Start After Jogging

There are a number of reasons why the torch might need to be jogged to a different location during

Program Pause, such as:

1) Lost cut requiring cleaning or changing of the nozzle;

2) Need to re-pierce in the scrap or on the plate edge instead of on the programmed path;

3) Need to re-locate the program during a dry-run, so that it will fit on the plate.

When the machine has been jogged during Program Pause, and the program needs to be re-started,

there are options available to handle each of the above situations.

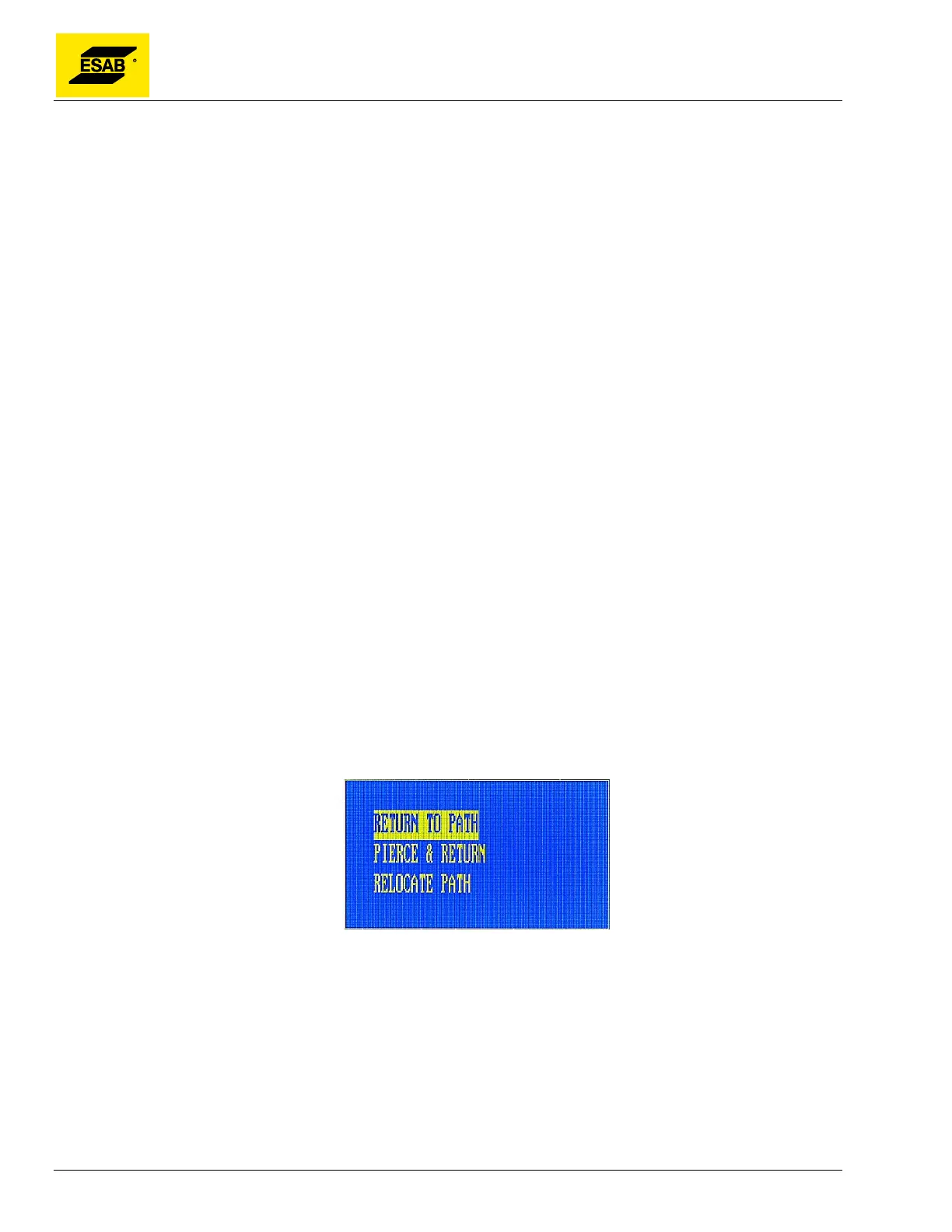

To re-start the program after jogging, press the 【START】 button. The following dialog box will

appear:

Figure 64: Re-Start After Jogging Options

Use the Up【↑】and Down【↓】keys to highlight the desired option. If flame cutting, preheat the plate

first. When ready, press the 【START】 key or the 【ENTER】 key to select the desired operation.

The three options are explained below:

1) RETURN TO PATH

Return the cutting torch to the point where it left the programmed path at rapid positioning speed, and

then pause. This allows the operator to send the machine quickly back to the programmed path, and

then manually re-start the process before continuing on path. After manually starting the cutting

Loading...

Loading...