ESAB Cutting Systems

CROSSBOW Page 110

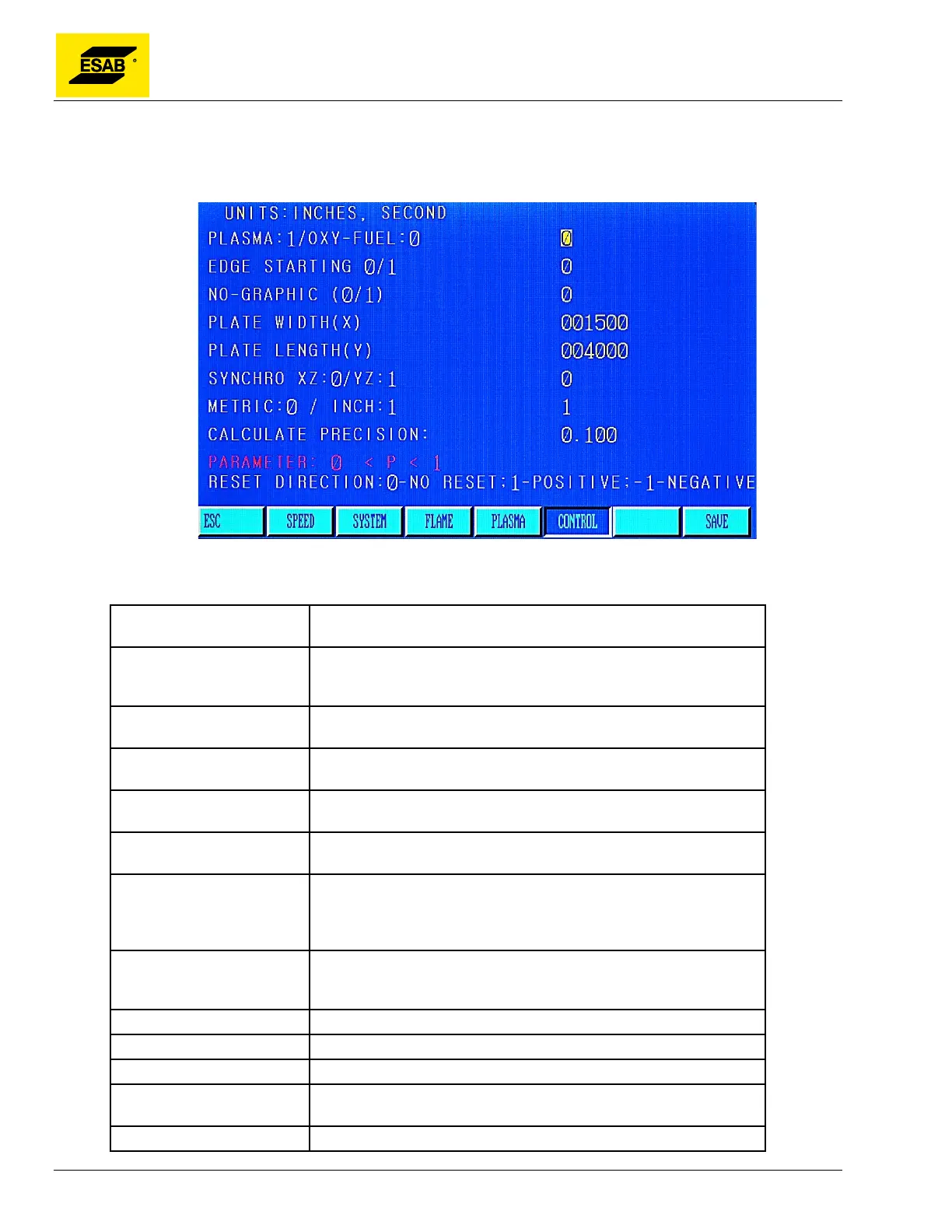

4.25.5 【F5】Control Parameters

In the SETUP menu, press the【F5】key to enter the CONTROL parameter page:

Figure 89: CONTROL Parameters

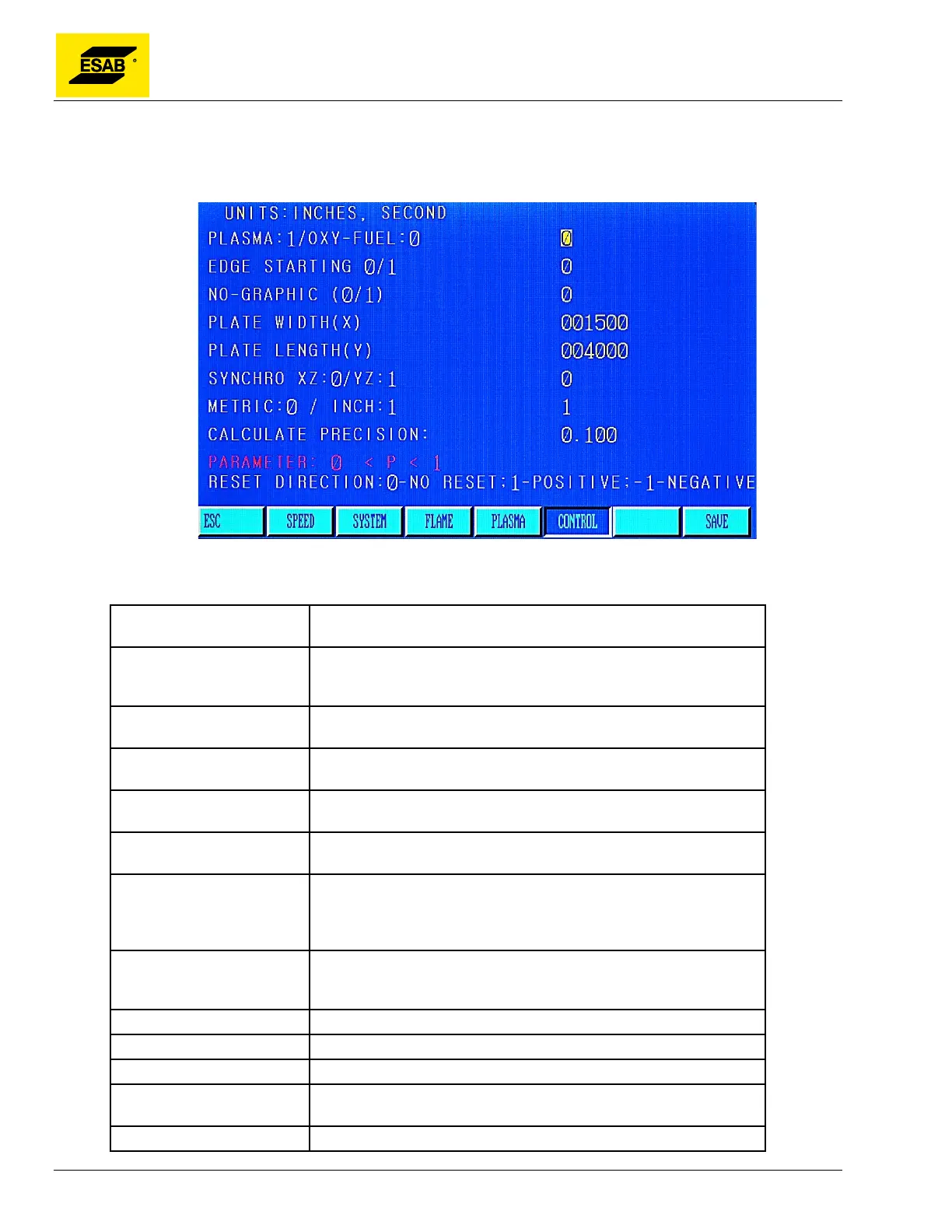

CONTROL Parameters

PLASMA / OXY-FUEL

Selection to pick which process to use. Activates the appropriate

process controls in Auto and Manual modes.

EDGE STARTING

This parameter activates edge starting for cutting thicker materials.

When enabled, the operator is prompted to move the torch to the

plate edge prior to each pierce.

NO-GRAPHIC

Do not draw graphic of program in Auto Mode. This option can

save time if cutting a large program.

PLATE WIDTH (X)

Actual width of steel plate in X axis. Only used when running very

large programs.

PLATE LENGTH (Y)

Actual length of steel plate in Y axis. Only used when running very

large programs.

SYNCHRO XZ / YZ

For dual-side drive gantries, selects whether Z-axis is synchronized

with X-axis or Y-axis. Not used on Crossbow.

METRIC / INCH

Enter 0 for Metric, 1 for Inch. The CNC will show length and speed

values in the appropriate system. Regardless of which setting is

used, the system can still run part program with mm dimensions by

using the G21 code, or Inch dimensions by using the G20 code.

CALCULATE PRECISION

Default value is 0.1mm. Changing this value can eliminate some

positioning calculation errors caused by rounding in the nesting

software.

EXTERNAL CTRL Not used on Crossbow.

WIRED/WIRELESS CTRL Not used on Crossbow.

KERF CHECK ON/OFF Check for kerf errors, yes or no.

RESET COORDINATES

Automatically sets Program Coordinates to zero when a program is

started.

AIR CYLINDER AHC Not used on Crossbow.

Loading...

Loading...