The substrate is not at

If the substrate does not lie at when it comes out of the printer, but has shallow waves in it, you are likely to

see defects in the printed image, such as vertical stripes. This can happen when you use thin substrate that

becomes saturated with ink; it can also be caused by the combination of heat and vacuum pressure that is

applied to the substrate.

1. Check that the substrate type you have loaded corresponds to the substrate type selected in the Internal

Print Server and in your software.

2. If you are using a paper-based substrate, try changing to a thicker substrate, or reduce the amount of

ink.

Assemble the dual-roll center support

Use the Dual Roll Center Support to ensure that no part of the substrate path suers from an excess of

tension due to the weight of the substrate. When the weight of the substrate is high, the absence of this

accessory could increase the risk of a printhead crash, which decreases printhead life as well as spoiling the

current print.

NOTE: There are two dual-roll center supports. The support base marked “I” is for the input dual-roll spindle

at the rear of the printer. Use the longer support shaft with the support base marked “I”. The support base

marked “O” is for the output dual-roll spindle at the front. Use the shorter support shaft with this support

base.

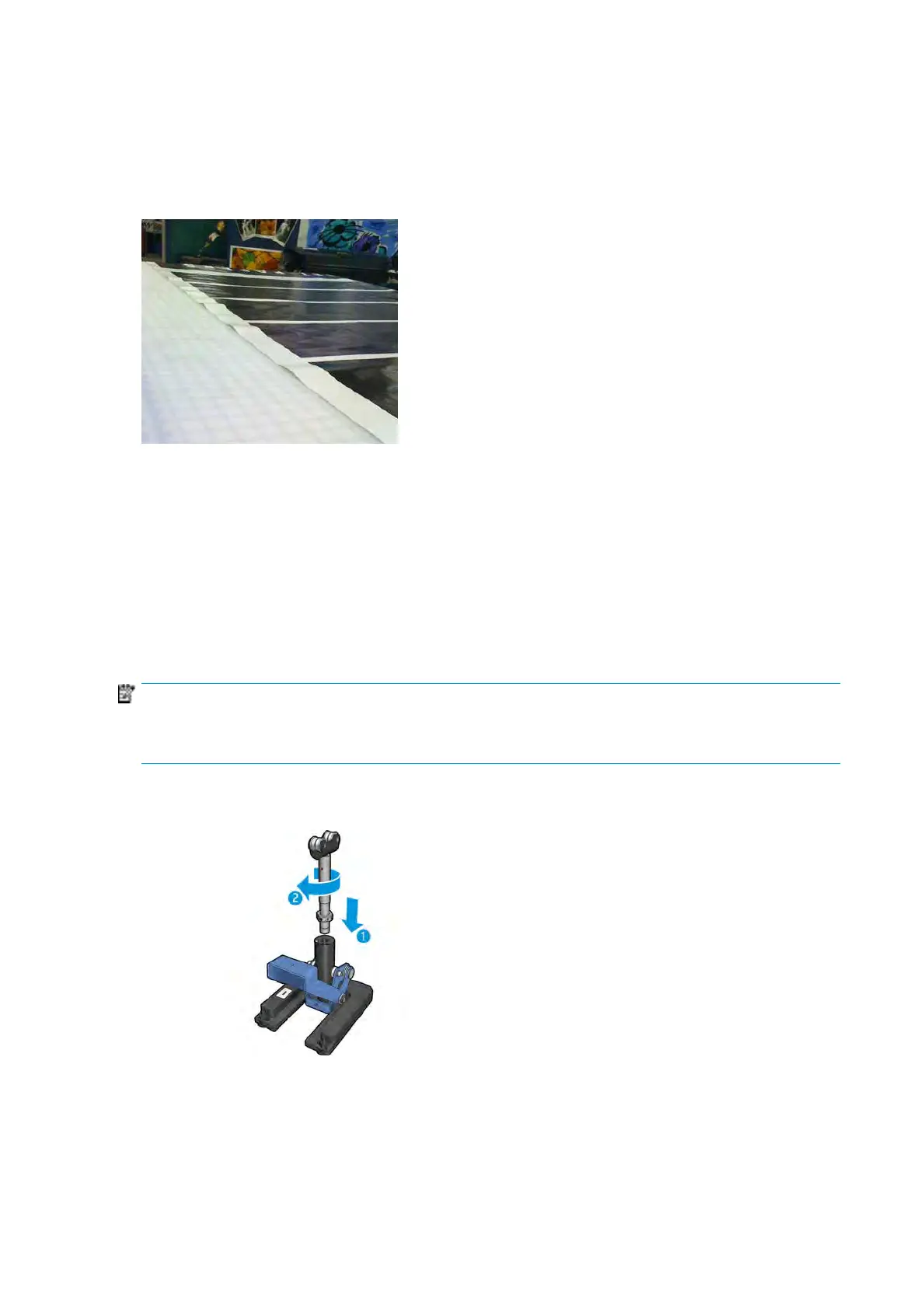

1. To assemble the input dual-roll center support (marked I), insert the top shaft into the support base and

turn.

296 Chapter 9 Troubleshoot substrate issues ENWW

Loading...

Loading...